High sensitivity active GNSS ceramic antennas are already transforming a wide range of industries by enabling reliable positioning in environments where standard antennas fail. As technology advances and new use cases emerge, their applications will expand further, and innovative trends will shape their design and functionality. This section explores the current key applications of these antennas and the future trends that will drive their evolution.

5.1 Current Key Applications

5.1.1 IoT Asset Tracking

The IoT asset tracking market is one of the largest adopters of high sensitivity active GNSS ceramic antennas, as it requires reliable positioning of assets in diverse environments—from shipping containers in ports to delivery packages in urban areas.

Shipping and Logistics: Shipping containers stacked in ports are surrounded by metal structures that block GNSS signals, resulting in weak or intermittent signal reception. High sensitivity antennas can capture these weak signals, enabling real-time tracking of containers as they move through ports, onto ships, and to their final destinations. For example, a logistics company using high sensitivity antennas in its container trackers can reduce the time spent searching for misplaced containers by 40%, improving operational efficiency and reducing costs.

Last-Mile Delivery: Delivery drones and vehicles operating in urban canyons face challenges with weak GNSS signals due to tall buildings. High sensitivity antennas allow these devices to maintain positioning accuracy of 5-10 meters, ensuring that packages are delivered to the correct address. For example, a drone delivery service in a major city can use high sensitivity antennas to navigate between skyscrapers and deliver packages to rooftop drop-off points with minimal errors.

Cold Chain Logistics: Assets in cold chain logistics (e.g., refrigerated trucks transporting food or pharmaceuticals) require positioning and temperature monitoring. High sensitivity antennas are designed to operate in extreme temperatures (-40°C to 85°C), making them suitable for this application. The antenna’s low power consumption also ensures that the tracker’s battery lasts for months, even in cold conditions where battery performance typically degrades.

5.1.2 Automotive and Autonomous Vehicles

The automotive industry relies on high sensitivity active GNSS ceramic antennas for telematics, navigation, and autonomous driving—applications that require precise and reliable positioning in all environments.

Telematics: Automotive telematics devices use GNSS antennas to track vehicle location, speed, and driver behavior. High sensitivity antennas ensure that these devices can maintain positioning even when the vehicle is in urban canyons or under bridges—critical for fleet management and insurance telematics (e.g., pay-as-you-drive insurance). For example, a fleet management company can use high sensitivity antennas to monitor the location of its trucks in real time, optimizing routes and reducing fuel consumption by 15%.

Advanced Driver Assistance Systems (ADAS): ADAS features like adaptive cruise control and lane-keeping assist require precise positioning to function correctly. High sensitivity antennas provide the sub-10-meter accuracy needed for these systems, even in weak-signal environments. For example, an ADAS-equipped car using a high sensitivity antenna can maintain its lane position on a highway surrounded by tall trees, which would block signals for standard antennas.

Autonomous Vehicles: Fully autonomous vehicles require centimeter-level positioning accuracy to navigate safely. While high sensitivity active GNSS ceramic antennas alone cannot achieve this level of accuracy, they are a critical component of hybrid positioning systems that combine GNSS with other technologies—such as LiDAR, radar, and inertial measurement units (IMUs). The antenna provides the base GNSS positioning, while the other technologies correct for errors and fill in gaps when GNSS signals are weak.

5.1.3 Wearable Devices

Wearable devices like smartwatches, fitness trackers, and medical wearables use high sensitivity active GNSS ceramic antennas to provide location-based features—while maintaining a compact form factor and long battery life.

Fitness and Outdoor Wearables: Fitness trackers and outdoor smartwatches use GNSS antennas to track running routes, hiking trails, and cycling distances. High sensitivity antennas allow these devices to maintain positioning accuracy in dense forests or mountainous areas, where signals are scattered by trees and terrain. For example, a hiker using a smartwatch with a high sensitivity antenna can track their location in a dense pine forest, where a standard antenna would lose signal.

Medical Wearables: Medical wearables for patients with chronic conditions (e.g., Alzheimer’s disease or diabetes) use GNSS antennas to provide real-time location monitoring. High sensitivity antennas ensure that these devices can track patients even when they are indoors (e.g., in a hospital or nursing home) or in urban areas. For example, a caregiver can use a medical wearable with a high sensitivity antenna to track a patient with Alzheimer’s who wanders into a shopping mall, ensuring their safe return.

Sports Performance Monitoring: Professional sports teams use wearables with GNSS antennas to monitor athletes’ movements and performance during training and games. High sensitivity antennas provide accurate positioning data even in stadiums surrounded by large structures (e.g., bleachers or scoreboards), allowing coaches to analyze players’ speed, distance covered, and positioning on the field.

5.1.4 Smart Cities and Urban Infrastructure

Smart cities use high sensitivity active GNSS ceramic antennas to monitor and manage urban infrastructure—such as traffic lights, streetlights, and waste management systems.

Traffic Management: Smart traffic lights and traffic cameras use GNSS antennas to synchronize their operations and monitor traffic flow. High sensitivity antennas allow these devices to maintain time synchronization (critical for traffic light coordination) even in urban canyons, where standard antennas struggle with weak signals. For example, a city can use high sensitivity antennas in its traffic management system to reduce traffic congestion by 25% by optimizing traffic light timing based on real-time traffic flow.

Waste Management: Smart waste bins equipped with GNSS trackers use high sensitivity antennas to alert waste management teams when they are full. These trackers operate in urban areas and near buildings, where signals are weak, but the high sensitivity antenna ensures that the bin’s location is always visible. For example, a city can reduce fuel consumption by 30% by using these trackers to optimize waste collection routes, avoiding unnecessary trips to empty bins.

Infrastructure Monitoring: Sensors attached to bridges, tunnels, and buildings use high sensitivity GNSS antennas to monitor structural health and detect movement (e.g., due to earthquakes or erosion). The antenna’s ability to operate in remote or urban areas ensures that these sensors can provide continuous data, helping engineers identify potential structural issues before they become critical.

5.2 Future Trends

5.2.1 Integration with AI for Adaptive Signal Optimization

One of the most promising future trends for high sensitivity active GNSS ceramic antennas is the integration of artificial intelligence (AI) to enable adaptive signal optimization. AI algorithms will analyze real-time data from the antenna (e.g., signal strength, noise levels, and interference sources) and adjust the antenna’s parameters (e.g., gain, resonant frequency, and filter bandwidth) to maximize performance in changing environments.

Real-Time Interference Mitigation: AI algorithms will detect interference from sources like Wi-Fi or cellular networks and adjust the filter’s bandwidth to attenuate the interfering signal. For example, if the antenna detects a strong 2.4 GHz Wi-Fi signal, the AI can narrow the filter’s passband to block the Wi-Fi frequency while maintaining coverage of GNSS bands.

Dynamic Gain Adjustment: The AI will adjust the LNA’s gain based on signal strength—increasing gain for ultra-weak signals (-170 dBm) and reducing gain for stronger signals (-150 dBm) to avoid distortion. This dynamic adjustment will improve the antenna’s linearity and reduce power consumption, as the LNA does not need to operate at maximum gain at all times.

Predictive Maintenance: AI will analyze historical performance data to predict when the antenna may fail (e.g., due to component degradation or environmental damage). This allows for proactive maintenance, reducing downtime for critical applications like autonomous vehicles or asset tracking.

AI integration will require the antenna to include a small microcontroller and memory to run the algorithms, but advances in low-power microchips will ensure that this does not significantly increase the antenna’s power consumption or size.

5.2.2 Miniaturization with MEMS Technology

Micro-Electro-Mechanical Systems (MEMS) technology will drive further miniaturization of high sensitivity active GNSS ceramic antennas, making them suitable for even smaller devices—such as tiny IoT sensors, implantable medical devices, and smart contact lenses.

MEMS-Based Ceramic Elements: MEMS technology allows for the fabrication of ceramic elements with dimensions as small as 2mm × 2mm × 0.5mm—far smaller than current 6mm × 6mm antennas. These tiny elements use microfabrication techniques to create precise patch structures and ground planes, ensuring that they maintain high sensitivity despite their size.

Integrated MEMS LNAs: MEMS technology can also be used to fabricate ultra-small LNAs using GaAs or SiGe transistors. These MEMS LNAs have a noise figure of 0.5-0.8 dB (same as current LNAs) but occupy only 10% of the space, allowing for full integration of the antenna, LNA, filter, and matching network into a single MEMS chip.

Implantable Medical Applications: Miniaturized high sensitivity antennas using MEMS technology will enable new implantable medical devices—such as glucose sensors or pacemakers with location tracking. These devices can use the antenna to transmit location data to external receivers, allowing doctors to monitor patients’ movements and ensure that the device remains in place.

MEMS-based miniaturization will not only reduce the antenna’s size but also lower its cost, as MEMS devices can be mass-produced using standard semiconductor manufacturing processes.

5.2.3 Multi-Band and Multi-Technology Integration

Future high sensitivity active GNSS ceramic antennas will support an even wider range of frequencies and integrate with other positioning technologies to provide seamless indoor-outdoor positioning.

Expanded GNSS Band Support: In addition to current bands (GPS L1, GLONASS G3, Galileo E1, BeiDou B1), future antennas will support newer GNSS bands—such as GPS L5 (1176.45 MHz), Galileo E5 (1191.795 MHz), and BeiDou B2 (1207.14 MHz). These bands offer better signal penetration and resistance to interference, further improving the antenna’s performance in weak-signal environments.

Integration with UWB and BLE: High sensitivity GNSS antennas will be integrated with UWB and BLE modules in a single package, creating hybrid positioning systems that provide accurate positioning both indoors and outdoors. The GNSS antenna handles outdoor positioning, while UWB or BLE handles indoor positioning—with seamless handoff between the two technologies as the device moves from outdoor to indoor spaces.

5G Integration: 5G networks will provide additional positioning capabilities through cell-based positioning (e.g., timing advance or angle of arrival). Future high sensitivity GNSS antennas will integrate with 5G modules to combine GNSS and 5G positioning, providing even higher accuracy and reliability in urban areas where 5G infrastructure is dense.

5.2.4 Sustainable and Eco-Friendly Designs

As the world focuses on sustainability, future high sensitivity active GNSS ceramic antennas will adopt eco-friendly designs to reduce their environmental impact.

Recyclable Materials: Manufacturers will use recyclable ceramic materials (e.g., alumina, which is fully recyclable) and biodegradable encapsulation materials (e.g., plant-based epoxies) to reduce waste. These materials will maintain the antenna’s performance while making it easier to recycle at the end of its lifespan.

Energy Harvesting: Antennas will integrate small energy harvesting modules—such as solar cells or vibration harvesters—to power the LNA and other components. This will reduce reliance on disposable batteries, making the antenna more sustainable for long-term IoT applications (e.g., sensors deployed in remote areas).

Low-Power Manufacturing: Manufacturing processes for high sensitivity antennas will be optimized to reduce energy consumption. For example, sputtering processes used to deposit conductive layers on ceramic elements will use less energy, and curing processes for encapsulation materials will operate at lower temperatures.

Conclusion

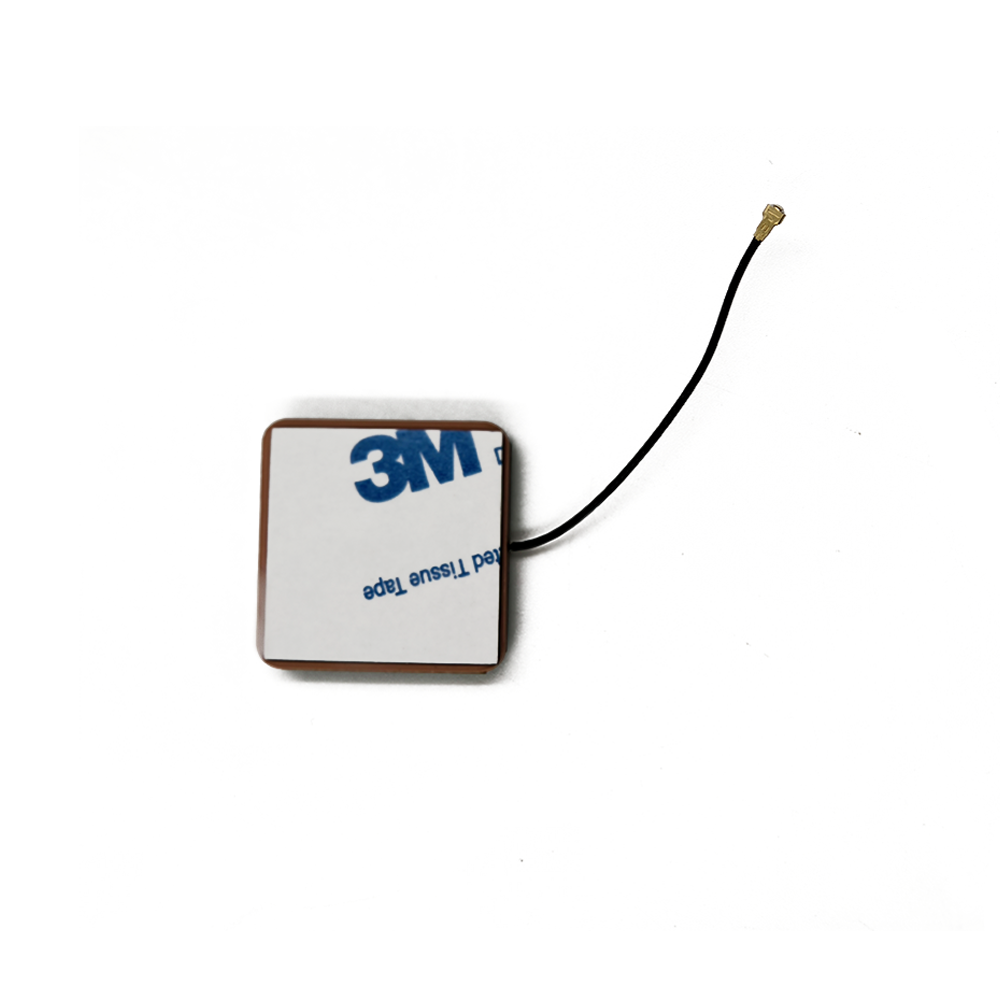

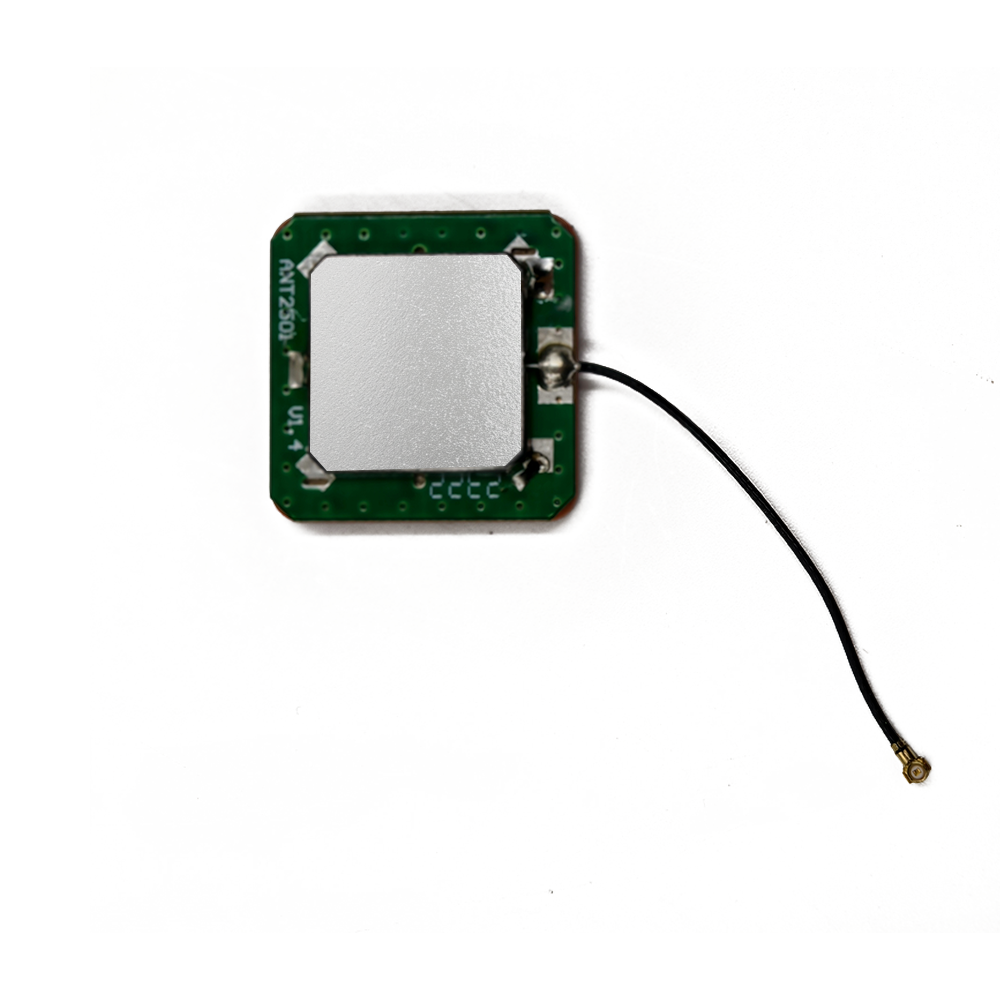

High sensitivity active GNSS ceramic antennas represent a transformative technology in the field of positioning, addressing the critical limitation of standard antennas—their inability to operate reliably in weak-signal environments. By combining a compact ceramic element, ultra-low-noise LNA, and high-performance filter, these antennas can detect signals as low as -165 dBm to -170 dBm, enabling reliable positioning in urban canyons, indoor spaces, dense forests, and remote rural areas. Their small size (6mm × 6mm to 15mm × 15mm), low power consumption (5-10 mA), and multi-constellation support make them indispensable for a wide range of applications—from IoT asset tracking to autonomous vehicles and wearable devices.

As we have explored, these antennas offer significant advantages over standard GNSS antennas: they expand the range of environments where positioning is possible, integrate seamlessly into space-constrained devices, and reduce operational costs for industries like logistics and automotive. However, they also face challenges—including higher cost, sensitivity to EMI, temperature-induced performance degradation, and limited indoor positioning capabilities. These challenges are being addressed through innovations like low-cost SiGe LNAs, temperature-compensating materials, and hybrid positioning systems, making high sensitivity active GNSS ceramic antennas more accessible and versatile.

Looking to the future, the evolution of these antennas will be driven by AI integration, MEMS-based miniaturization, multi-technology fusion, and sustainable design. AI will enable adaptive signal optimization, ensuring that the antenna performs optimally in changing environments. MEMS technology will shrink the antenna to microscopic sizes, opening up new applications in implantable medical devices and tiny IoT sensors. Integration with 5G, UWB, and BLE will provide seamless indoor-outdoor positioning, eliminating the gap between outdoor GNSS and indoor positioning. And sustainable designs will reduce the antenna’s environmental impact, aligning with global efforts to build a more eco-friendly electronics industry.

In conclusion, high sensitivity active GNSS ceramic antennas are not just a technical advancement—they are a enabler of a more connected, efficient, and safe world. By making reliable positioning ubiquitous, they will transform industries, improve the user experience of consumer devices, and support the development of smart cities and autonomous systems. As technology continues to advance, these antennas will remain at the forefront of positioning innovation, helping to shape the future of how we track, navigate, and interact with the world around us.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)