The unique capabilities of high-precision ceramic patch antennas have enabled a technological revolution across a diverse spectrum of industries. Their journey began in specialized fields but is rapidly expanding into mass-market applications.

Current Applications:

Geomatics and Surveying: This is the traditional and most demanding domain. RTK-GPS systems used for land surveying, construction site preparation, and civil engineering require the ultimate in phase center stability and multipath rejection. These antennas are often mounted on fixed-height poles or integrated into ruggedized, survey-grade receivers, sometimes coupled with external choke rings for the most challenging environments.

Precision Agriculture (AgriTech): This is a major growth area. GPS-guided tractors and harvesters use RTK for auto-steering, achieving sub-inch pass-to-pass accuracy. This eliminates overlaps and gaps in planting, spraying, and harvesting, leading to massive savings in fuel, seed, fertilizer, and time. Variable Rate Technology (VRT) uses precise position data to apply inputs only where needed.

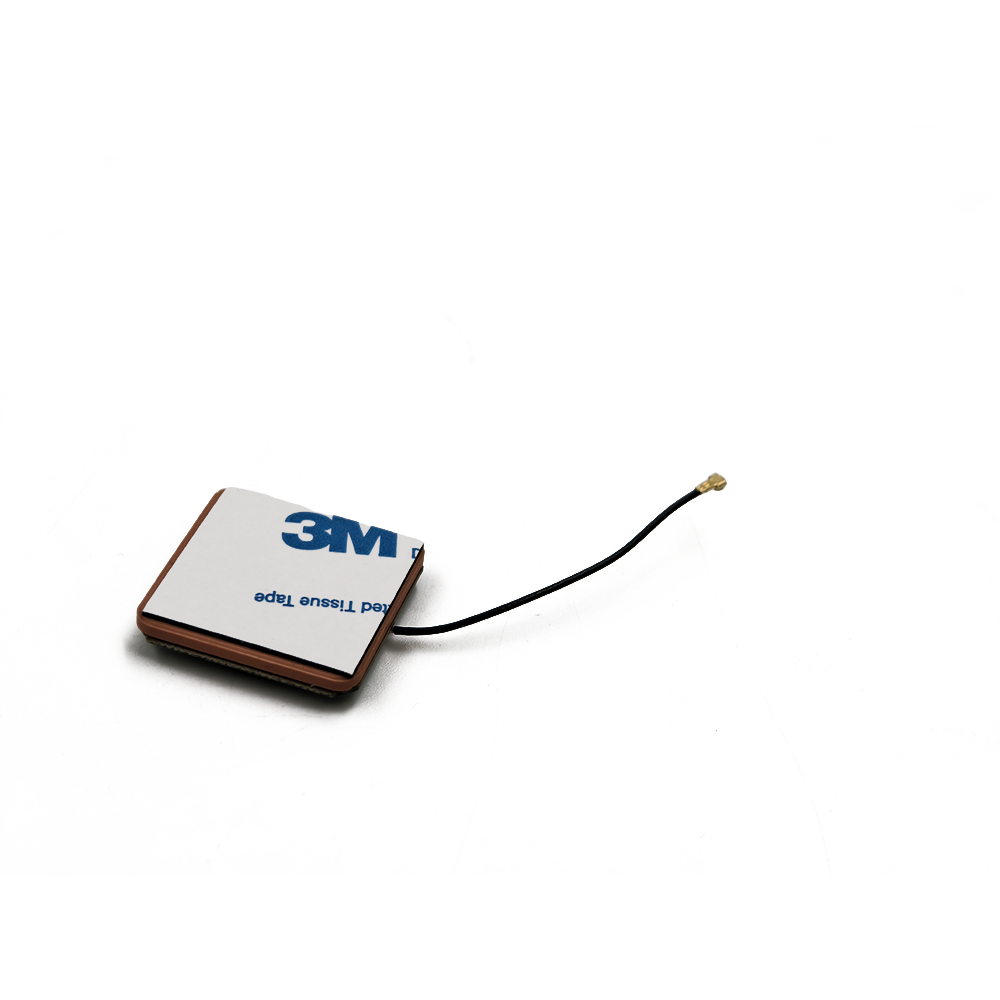

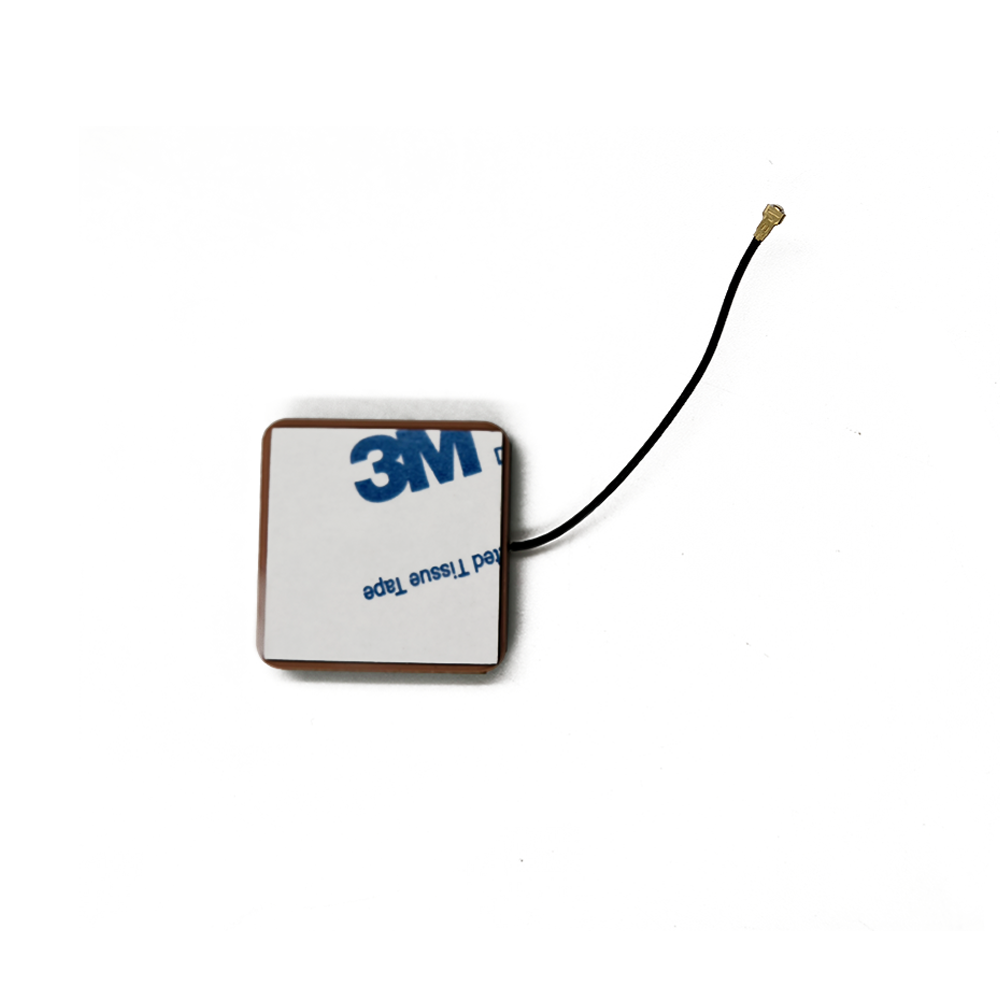

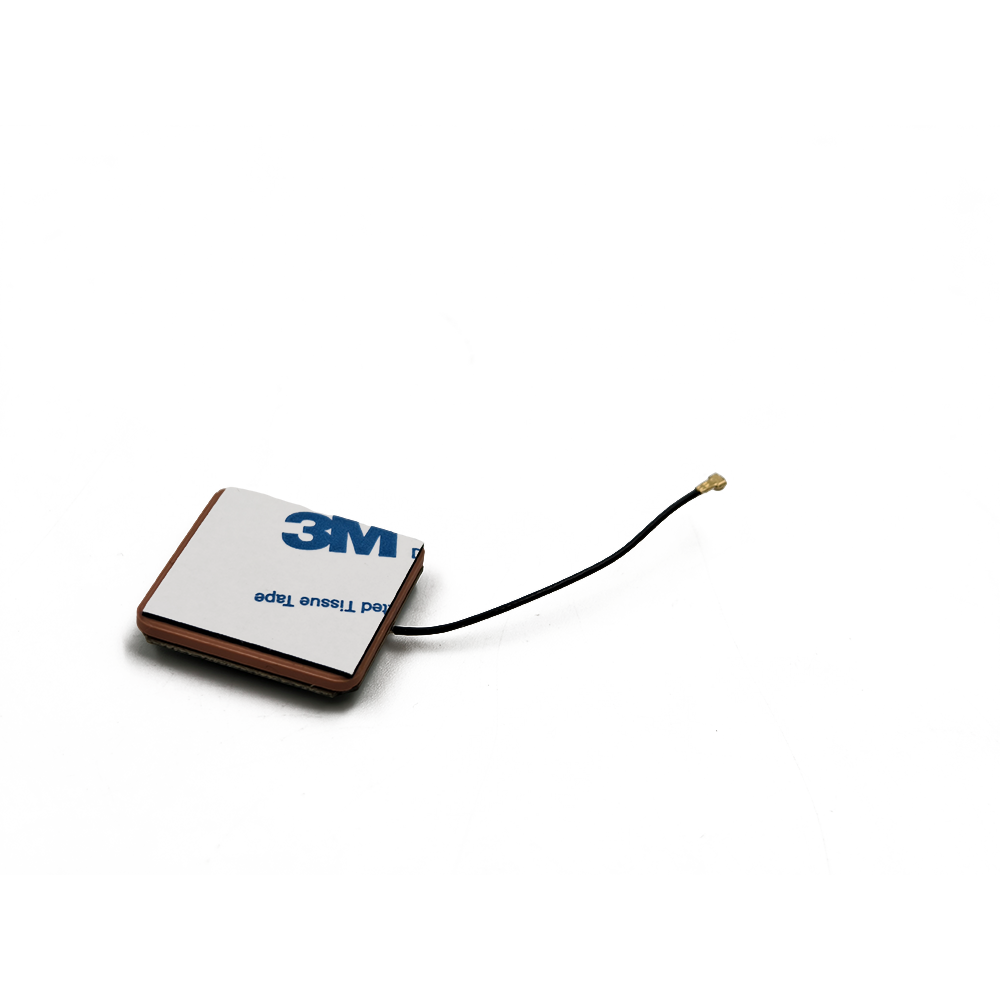

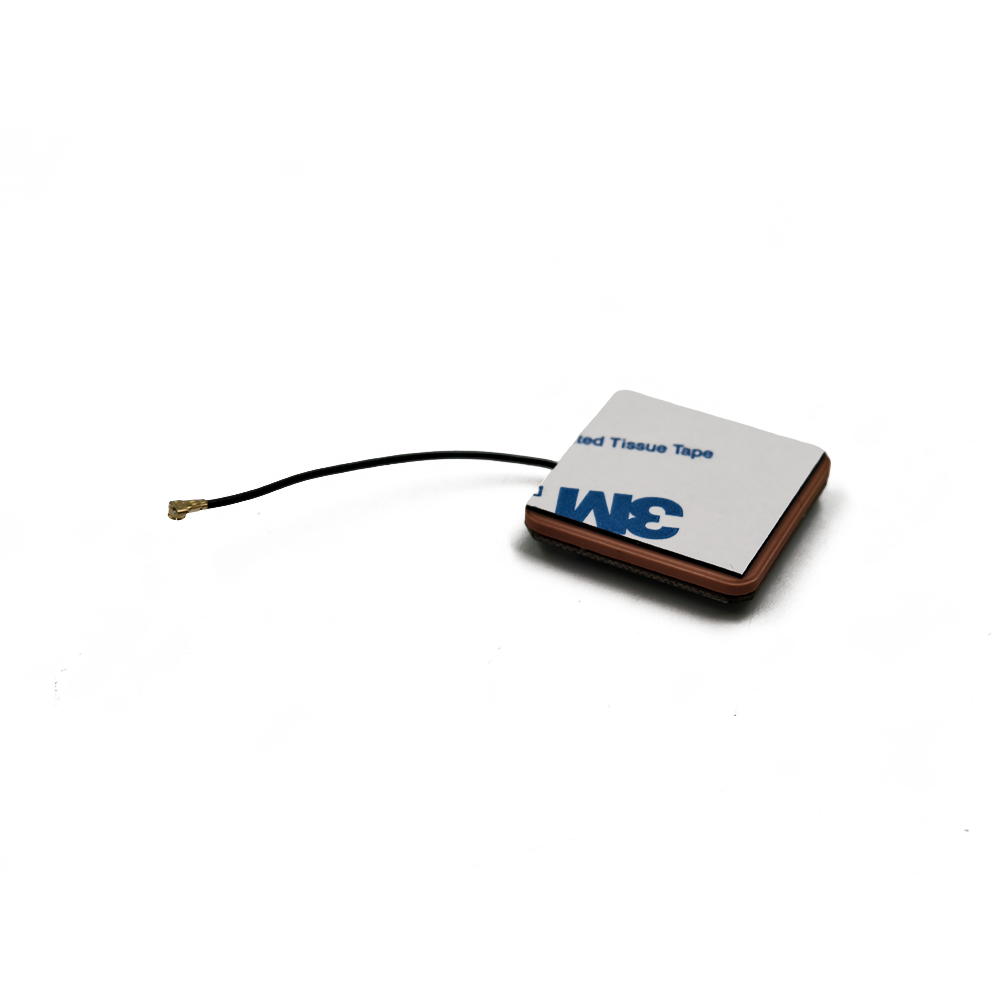

Unmanned Aerial Vehicles (Drones) and Robotics: The small size and light weight of ceramic patches make them ideal for drones. They are used for precision mapping, photogrammetry, agricultural spraying, and infrastructure inspection. In robotics, they enable autonomous navigation for warehouse robots, lawn mowers, and last-mile delivery vehicles.

Marine and Autonomous Shipping: High-precision GNSS is critical for harbor navigation, dredging, hydrographic surveying, and the emerging field of autonomous surface vessels. The antenna's ruggedness and corrosion resistance are key benefits in the harsh marine environment.

Aviation: Aircraft navigation, especially during approach and landing phases (GBAS - Ground-Based Augmentation System), requires extremely high integrity and precision. Ceramic patch arrays are used in aviation-grade receivers.

Scientific and Timing Applications: Scientific applications like crustal deformation monitoring for earthquake prediction and glacier flow tracking require long-term, millimeter-level stability. GNSS is also a primary source for precise time synchronization in telecommunications networks (4G/5G base stations), financial trading networks, and power grids, where a stable antenna phase center is critical for nanosecond-level timing accuracy.

Automotive and Autonomous Vehicles (ADAS): This is the frontier for mass adoption. Lane-level positioning is crucial for Advanced Driver Assistance Systems (ADAS) and the path towards full autonomy. High-precision ceramic patches are being integrated into vehicle rooflines and dashboards to provide continuous, reliable position, velocity, and time (PVT) data, fusing with LiDAR, radar, and cameras.

Future Trends:

Multi-Band, Multi-Constellation Operation: The future is about receiving all signals from all constellations (GPS, Galileo, GLONASS, BeiDou) across all frequencies (L1, L2, L5, etc.). This "constellation redundancy" improves accuracy, availability, and reliability. Antenna design will focus on achieving ultra-wideband performance covering 1.1 GHz to 1.6 GHz in a single, compact element.

Integrated Active Antennas: The trend is towards tighter integration of the antenna element with a Low-Noise Amplifier (LNA) and often a bandpass filter into a single sealed module. This "active antenna" improves the overall system noise figure and protects the weak signal from being degraded by loss in the coaxial cable before amplification.

Advanced Multipath Mitigation: Research continues into improving built-in multipath rejection without increasing size. This includes designs with integrated artificial magnetic conductor (AMC) surfaces or electromagnetic bandgap (EBG) structures that act like miniature, integrated choke rings.

Antenna Arrays and Beamforming: For automotive and other challenging environments, single antennas are vulnerable to jamming and spoofing. The future lies in multi-element ceramic patch arrays that can electronically steer their beam towards desired satellites and null interference sources. This Controlled Reception Pattern Antenna (CRPA) technology is becoming more compact and affordable.

"Smart" or Cognitive Antennas: Integrating processing capabilities with the antenna to allow it to adapt in real-time to its RF environment—for example, by dynamically adjusting its pattern to nullify a newly detected jamming signal.

Enhanced Integration and Aesthetics: For consumer automotive, the antenna must disappear. Future designs will be fully integrated into the vehicle's glass (as printed patches), body panels, or plastic components, providing high performance without a visible "shark-fin" or puck.

The high-precision ceramic patch antenna, therefore, is not a static technology. It is continuously evolving to meet the ever-increasing demands of accuracy, reliability, and integration, solidifying its role as the essential gatekeeper to the world of precise positioning.

Conclusion

The high-precision ceramic patch GPS antenna is a masterpiece of engineering that exemplifies the profound impact a single, well-designed component can have on an entire technological ecosystem. It is far more than a passive receiver; it is the critical front-end that defines the ultimate performance ceiling of any high-precision GNSS system. Its journey from a theoretical concept to a mass-produced, highly calibrated instrument underscores its successful balance of physics, materials science, and practical application needs.

This series has detailed its inner workings: from its overview as the foundation of modern positioning, through the meticulous design and construction that transforms ceramic and metal into a resonant cavity, to the fundamental physics that govern its operation. We have seen that its core value lies in its exceptional phase center stability, a characteristic that allows carrier-phase measurements to be translated into centimeter-level position accuracy. Its ability to reject multipath through careful pattern shaping and polarization purity further cements its role as the first and most important line of defense against error.

While it boasts significant advantages in size, robustness, and manufacturability, these benefits are not without their challenges. Engineers perpetually wrestle with the trade-offs between bandwidth, efficiency, size, and thermal stability. Overcoming these limitations requires continuous innovation in materials, feeding techniques, and bandwidth-enhancement strategies like stacked patches.

The applications for this technology are vast and growing, enabling revolutions in surveying, agriculture, robotics, and setting the stage for the autonomous future of transportation. As we look forward, the trends are clear: the antenna will become more integrated, more wideband, more intelligent, and even more central to systems that rely on flawless absolute positioning.

In conclusion, as GNSS signals travel over 20,000 km from medium Earth orbit, they arrive at Earth's surface incredibly weak and corrupted by a myriad of errors. The high-precision ceramic patch antenna stands as the dedicated sentinel, designed to capture these faint whispers from space with unwavering fidelity and stability. It is the indispensable gateway, the precise and stable starting point upon which all subsequent signal processing and calculation is built, making it the true cornerstone of modern high-precision navigation.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)