Overview

This device is not merely an antenna; it is a complete GNSS (Global Navigation Satellite System) subsystem. It integrates a high-precision ceramic patch antenna, a multi-band, multi-constellation GNSS receiver engine, an RTK correction processor, and supporting electronics into a single, miniaturized package designed for surface-mount technology (SMT) or easy embedding into a host device. Its primary function is to output not just raw satellite data, but a validated, centimeter-accurate position solution in real-time, drastically reducing the integration burden for OEMs (Original Equipment Manufacturers).

The evolution to this level of integration follows a clear trajectory. Historically, achieving RTK performance required a complex system: a separate, high-quality survey-grade antenna (often with a large ground plane or choke ring), a low-loss coaxial cable, and a standalone RTK GNSS receiver/processor unit. This system was bulky, expensive, power-hungry, and required significant expertise to integrate and operate. The compact module collapses this entire chain into a single PCB-mountable unit, often smaller than a credit card and only a few centimeters tall.

The driving force behind this miniaturization is the relentless demand from new markets. Consumer and industrial robotics, from warehouse logistics bots to autonomous lawn mowers, require precise positioning for navigation and task execution without the bulk of external components. Drones for mapping, surveying, and precision agriculture need lightweight, low-profile modules to maintain flight stability and payload capacity. Advanced automotive ADAS (Advanced Driver-Assistance Systems) and eventual autonomous vehicles require highly reliable, tamper-proof positioning that can be seamlessly integrated into the vehicle's roof or dashboard.

The "built-in" aspect is crucial. Unlike a module that simply provides a data output, an RTK module is designed to be an embedded component. It features standard mechanical mounting points, a defined antenna reference point (ARP) for precision, and communication interfaces like UART, SPI, I2C, or USB. It often comes with a complete software development kit (SDK), application programming interfaces (APIs), and detailed integration guidelines, allowing engineers to treat high-precision positioning as a solved problem—a black box that delivers a reliable coordinate stream.

Furthermore, these modules are designed to work within the constraints of modern electronic devices. They operate on low voltage (e.g., 3.3V or 5V), manage power consumption carefully with multiple sleep modes, and generate minimal RF noise to avoid interfering with other onboard sensors. They represent the culmination of advancements in ceramic material science, RF integrated circuit (RFIC) design, and embedded systems engineering, packaged to bring previously unattainable performance to mass-market applications. This overview sets the stage for understanding the intricate components and synergies that make this possible.

Design and Construction

The design of a compact built-in RTK module is a masterclass in miniaturization and RF integration, balancing conflicting demands of performance, size, thermal management, and isolation. Every cubic millimeter is optimized.

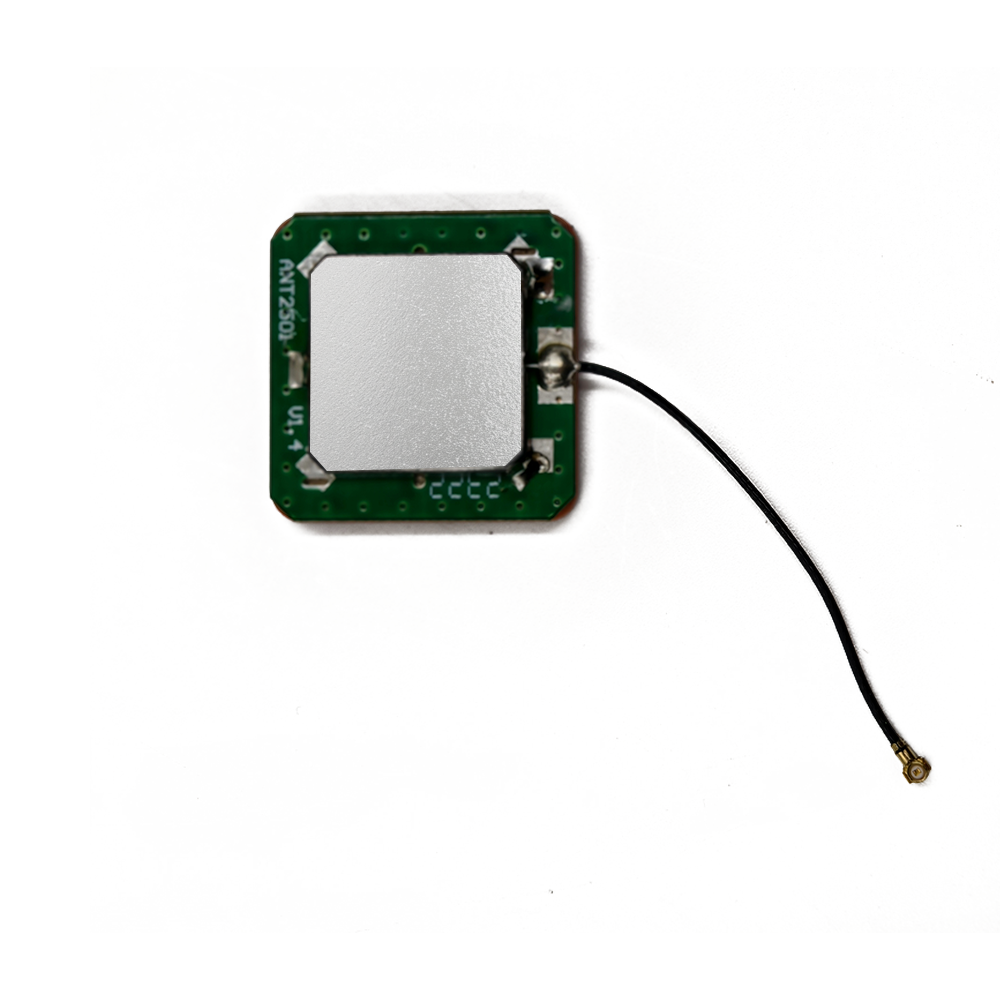

1. The High-Precision Ceramic Patch Antenna:

This is the module's front end and most visible component. Its design is more advanced than a standard patch.

Stacked Ceramic Design: To achieve the necessary bandwidth for receiving multiple GNSS bands (e.g., GPS L1/L2, Galileo E1/E5b, BeiDou B1/B2) crucial for RTK, a single patch is insufficient. Designers use a stacked-patch configuration. A smaller, high-dielectric constant ceramic patch is stacked on top of a larger, lower-dielectric constant patch. This creates two coupled resonant cavities, effectively creating a dual-band antenna within a single footprint.

Enhanced Ground Plane: The antenna is mounted on its own dedicated, continuous ground plane within the module. This is critical for maintaining a stable radiation pattern and phase center, independent of the host device's PCB layout, which can be electrically "noisy" and irregular.

Integrated Low-Noise Amplifier (LNA): Located immediately beneath the antenna feed point is a specialized GaAs or GaN FET-based LNA. Its position is strategic: it amplifies the extremely weak satellite signals (often below -130 dBm) before any significant loss can occur in the transmission line to the receiver chip. This is vital for maintaining a low overall system noise figure.

2. The RTK Engine and GNSS Receiver IC:

This is the brain of the module. It is a System-on-a-Chip (SoC) that integrates:

RF Front-End: Down-converts the amplified RF signals from the antenna to an intermediate frequency (IF) or directly to digital.

Multi-Channel Correlators: High-end modules possess hundreds of parallel channels to simultaneously track all visible satellites from multiple constellations (GPS, GLONASS, Galileo, BeiDou, QZSS) and multiple frequencies.

powerful CPU: A dedicated microprocessor runs the baseband processing, navigation algorithms, and the complex RTK engine. The RTK engine is responsible for resolving the integer ambiguities in the carrier-phase measurements by processing correction data from a base station or network.

Memory: Includes Flash memory for the firmware and SRAM for operational data and correction buffers.

3. Supporting Electronics and Power Management:

Timing Core: A highly stable temperature-compensated crystal oscillator (TCXO) or even an oven-controlled crystal oscillator (OCXO) provides the critical clock reference. Clock stability is paramount for accurate carrier-phase measurement.

Power Regulation: Multiple low-dropout regulators (LDOs) provide clean, stable voltages to the sensitive RF and digital sections, isolating them from noise on the host's power bus.

Interfaces: Level shifters and transceivers for communication protocols (UART, USB, SPI, I2C) and often a dedicated pulse-per-second (PPS) output for precise timing synchronization.

4. Packaging and Shielding:

Module PCB: A multi-layer PCB (often 6-8 layers) using high-quality, low-loss materials like FR-4 or Rogers laminate. This board hosts all components and provides intricate RF transmission lines with controlled impedance.

EMI/RFI Shielding: A metal can (typically soldered to the module's ground plane) is placed over the entire RF section and digital processor. This shielding is absolutely critical. It prevents internal digital noise from de-sensing the sensitive RF receiver and protects it from external electromagnetic interference from the host device's other components (processors, motors, radios).

Radome: The entire assembly is topped with a plastic radome. Its material is carefully chosen for minimal RF attenuation and signal distortion. It protects the fragile ceramic antenna from physical damage and environmental exposure.

5. Calibration and Testing:

This is what separates a precision module from a simple receiver. Each module design, or often each individual unit, undergoes rigorous testing in an anechoic chamber.

Phase Center Calibration: The exact phase center variation (PCV) of the integrated antenna is measured across all angles and frequencies. This data is used to generate an ANTEX (ANTenna EXchange) format calibration file unique to that module model.

Integration into Firmware: The sophisticated firmware of the RTK engine is pre-loaded with this PCV data. This means that before the raw carrier-phase measurements are even processed by the RTK algorithm, they are corrected for the known imperfections of its own antenna. This is a monumental advantage over a discrete design, where the antenna and receiver are calibrated separately and the end-user must manually apply corrections.

The construction is a harmonious integration of these subsystems, resulting in a component that is far greater than the sum of its parts—a calibrated, self-contained positioning instrument.

Working Principles

The operation of a compact RTK module is a complex, multi-stage process that transforms faint microwave signals from space into a centimeter-accurate position fix.

1. Signal Reception and Amplification:

The process begins at the ceramic patch antenna. RHCP signals from GNSS satellites induce tiny oscillating currents at the antenna's feed point. These incredibly weak signals, buried deep in thermal noise, are immediately amplified by the integrated LNA. This first amplification is critical for defining the system's overall signal-to-noise ratio (SNR).

2. Downconversion and Digitization:

The amplified RF signal is routed via a carefully designed microstrip transmission line on the module's PCB to the GNSS SoC. Inside the chip's RF front-end, the signal is mixed with a local oscillator signal (generated by the TCXO) to downconvert it to a lower intermediate frequency (IF) or directly to baseband. This analog signal is then converted into a digital bitstream by a high-speed analog-to-digital converter (ADC).

3. Correlation and Tracking:

The digital signal enters the correlator engines. Each correlator is assigned to search for and track a specific satellite's PRN (Pseudo-Random Noise) code. This process, known as parallel correlation, involves replicating the satellite's code and shifting it in time until it aligns (correlates) with the incoming signal. Once locked, the correlators continuously track the code phase and, more importantly, the phase of the carrier wave itself.

4. Raw Observation Generation:

For each tracked satellite, the receiver generates three key "observables":

Pseudorange: The code-phase-based distance measurement, accurate to about a meter.

Carrier Phase: The precise measurement of the phase of the carrier wave, accurate to a fraction of a wavelength (a few millimeters). However, this measurement is ambiguous by an unknown integer number of whole wavelengths (the "integer ambiguity").

Doppler Shift: The measured change in frequency, used to calculate velocity.

5. The RTK Engine: Resolving the Ambiguity

This is the core of the module's high-precision capability. The RTK engine receives a stream of correction data from a reference station or a network (via a cellular modem, WiFi, or radio link integrated into the host device). This data typically includes:

The reference station's precise coordinates.

The raw pseudorange and carrier-phase measurements from the reference station.

The engine then performs double-differencing:

Between Satellites: It calculates the difference between measurements from two different satellites made by the rover (the module) and the same two satellites made by the base station. This eliminates satellite clock errors.

Between Receivers: It calculates the difference between measurements from the same satellite made by the rover and the base station. This eliminates receiver clock errors.

The double-differenced carrier-phase measurement is virtually free from clock errors and atmospheric delays (if the base and rover are close, e.g., < 10 km). What remains is a measurement that is proportional to the geometric distance between the base and rover, plus the double-differenced integer ambiguity. The RTK engine's processing core employs sophisticated search algorithms (e.g., LAMBDA method) to rapidly resolve these integer ambiguities to their correct values. Once resolved, the carrier-phase measurements become ultra-precise range measurements.

6. Navigation Solution:

With the ambiguities resolved, the engine uses a Kalman filter or least-squares algorithm to compute its position relative to the base station. It fuses the ultra-precise carrier-phase ranges with the code-phase ranges and Doppler measurements to produce a final, validated output: latitude, longitude, and height with centimeter-level accuracy, along with velocity and time. This solution is then output via the serial interface to the host application.

This entire process, from signal reception to position output, happens in real-time, typically at update rates of 5-20 Hz, enabling dynamic platforms like drones and robots to navigate with precision.

Advantages and Challenges

-

Advantages:

Dramatically Simplified Integration: The primary advantage. OEMs can add high-precision GPS without deep RF or GNSS expertise. It reduces design time, testing, and certification efforts.

Guaranteed Performance: The module is pre-calibrated as a system (antenna + receiver). The end performance (accuracy, time-to-first-fix) is characterized and guaranteed by the manufacturer, reducing engineering risk.

Compact Form Factor: Its small size and low profile are enabling for applications where size and weight are critical constraints (drones, wearables, handhelds).

Improved Reliability: The module is a tested, certified, and shielded unit. Its performance is less susceptible to poor integration by the end-user, as the critical RF components are isolated from the host PCB.

Power Efficiency: Module designers optimize the entire system for power consumption, incorporating advanced sleep and wake-up modes that would be difficult to implement with discrete components.

Challenges and Limitations:

Thermal Management: The high level of integration concentrates heat-generating components (the processor, RF front-end) in a small, shielded area. Heat can destabilize the TCXO and LNA, degrading performance. Careful thermal design of the host PCB is often required.

Antenna Performance Compromise: The antenna's size is ultimately limited by the module's footprint. A smaller antenna has lower gain and a wider beamwidth, making it more susceptible to low-elevation multipath compared to a larger, external antenna.

Cost: High-performance modules, with their specialized components and calibration processes, are significantly more expensive than standard GPS modules. This can be a barrier for extremely cost-sensitive applications.

Dependency on Corrections: The module's high accuracy is entirely dependent on receiving timely, low-latency RTK correction data. If the cellular link is lost or the radio link is interrupted, the position will revert to a less accurate single-point solution.

Fixed Configuration: The module is a closed system. An integrator cannot upgrade just the antenna or just the receiver; they are locked into the manufacturer's chosen components and performance envelope.

Applications and Future Trends

-

Applications:

Autonomous Mobile Robots (AMRs): For navigation in warehouses, factories, and hospitals.

Unmanned Aerial Vehicles (UAVs): For precision agriculture, surveying, mapping, and infrastructure inspection.

Advanced Driver-Assistance Systems (ADAS): For lane-level positioning, providing a reliable input for automated driving functions.

Precision Agriculture: Not just for drones, but for autonomous tractors, harvesters, and implement control.

Industrial IoT and Asset Tracking: Monitoring high-value assets in ports, yards, and construction sites with centimeter accuracy.

Future Trends:

Tighter Sensor Fusion: Modules will increasingly integrate IMUs (Inertial Measurement Units) and barometers internally to provide seamless navigation through GNSS outages (e.g., in urban canyons, tunnels).

Cloud-RTK and PPP-RTK: Modules will natively support protocols for receiving corrections from global satellite-based augmentation systems, reducing reliance on local base stations.

Enhanced Security: Integration of hardware-based security features to prevent jamming, spoofing, and cyber-attacks, which is critical for autonomous systems.

AI/ML Integration: On-module machine learning cores to predict multipath, classify interference, and further optimize the navigation solution.

Conclusion

The compact built-in RTK GPS ceramic antenna module is a transformative technology. It has successfully packaged the complex science of high-precision GNSS into an accessible, reliable, and manufacturable component. By solving the profound challenges of integration, calibration, and miniaturization, it has broken down the barriers to entry for centimeter-level positioning. It is no longer a specialized tool but an enabling commodity, fueling innovation across robotics, automotive, and IoT industries and acting as a key catalyst for our autonomous future. Its development represents a pinnacle of systems engineering, making extreme precision available for any device, anywhere.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)