Active ceramic patch antennas with waterproof housing are already widely used across industries that demand reliable wireless connectivity in wet or harsh environments. As technology advances and new use cases emerge, their applications will expand further, and innovative trends will shape their design and functionality. This section explores the current key applications of these antennas and the future trends that will drive their evolution.

5.1 Current Key Applications

5.1.1 Outdoor IoT and Smart Agriculture

The outdoor IoT market relies heavily on these antennas to enable connectivity for sensors deployed in fields, forests, and remote areas—where exposure to rain, humidity, and dust is constant.

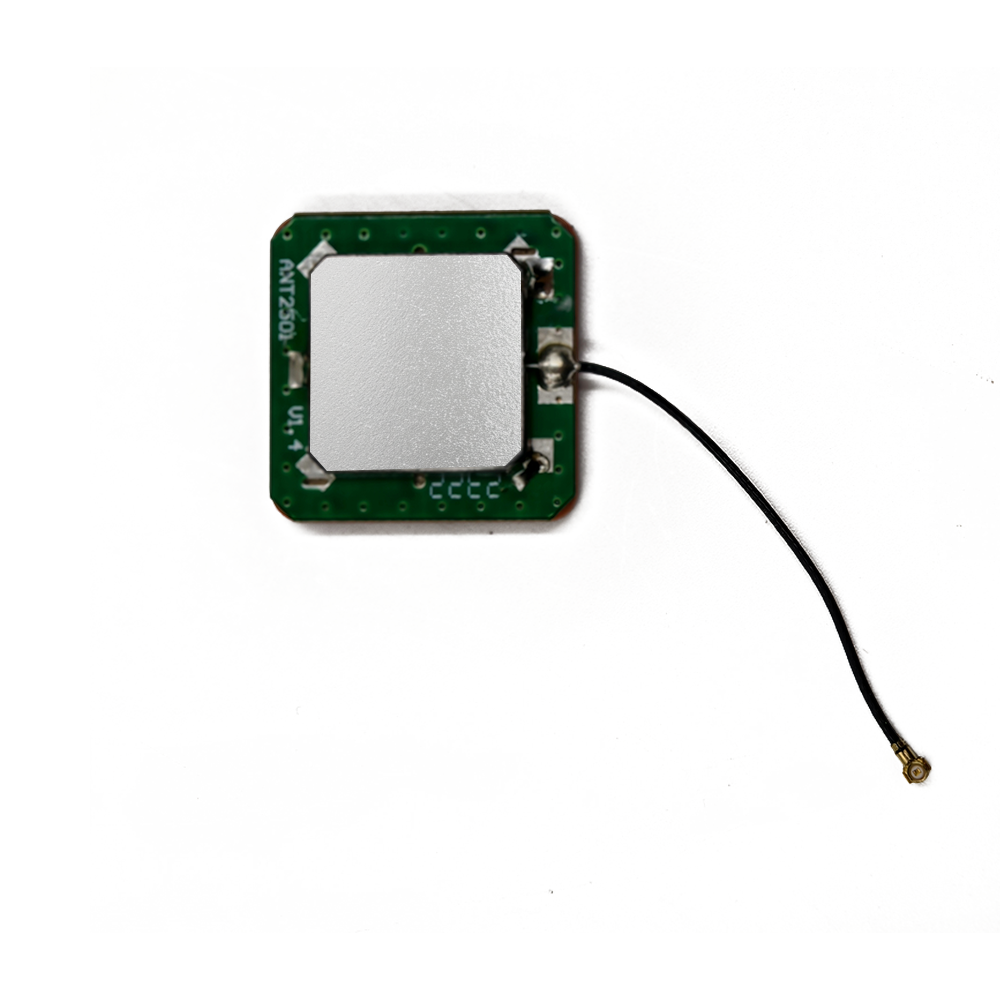

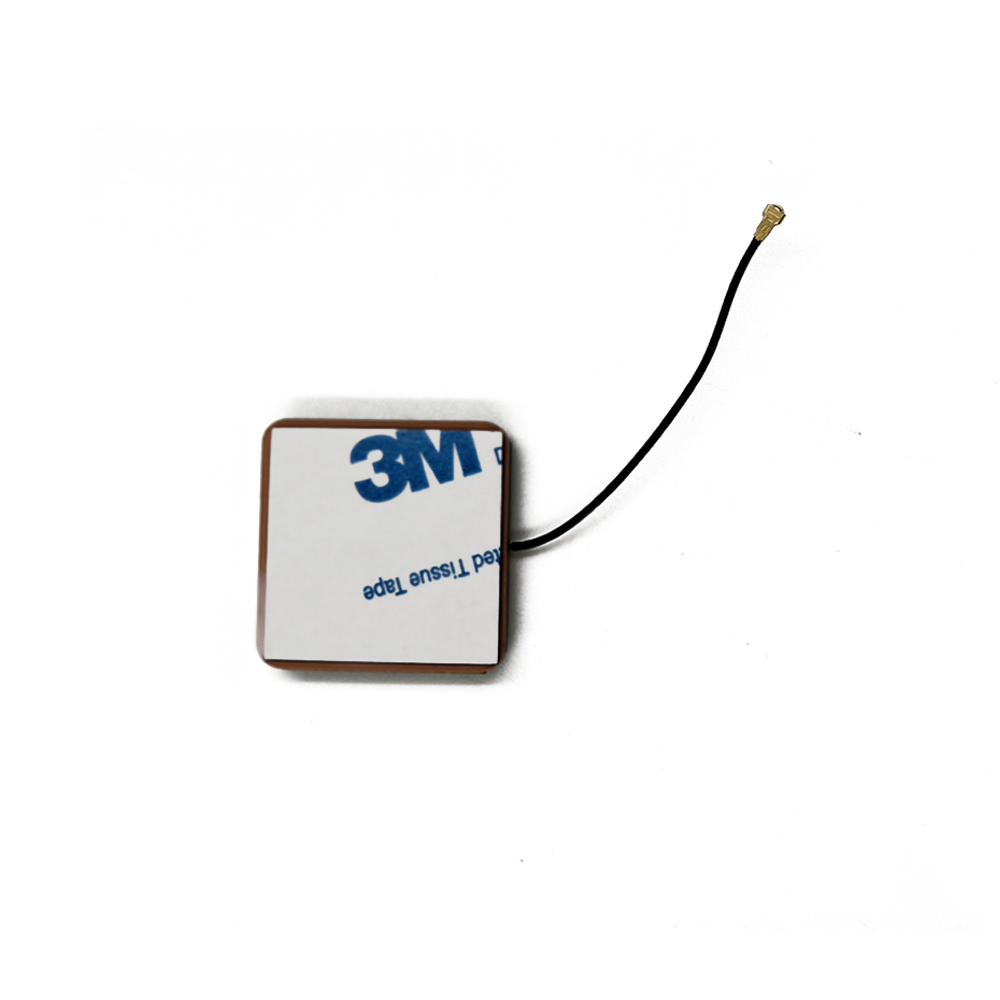

Soil Moisture and Crop Health Sensors: In smart agriculture, sensors equipped with waterproof active ceramic patch antennas monitor soil moisture, temperature, and crop health (via NDVI—Normalized Difference Vegetation Index). These sensors transmit data wirelessly (via LoRa or Wi-Fi) to a central gateway, even during heavy rain or irrigation. For example, a farmer in Iowa can use these sensors to track soil moisture levels in a cornfield, adjusting irrigation schedules to reduce water waste by 30%. The antenna’s compact size (8mm×8mm×3mm) allows it to fit in small sensor enclosures (20mm×20mm×10mm), and its low power consumption (10 mA) ensures the sensor operates for 6-12 months on a single battery.

Wildlife Tracking Collars: Conservation organizations use waterproof active ceramic patch antennas in wildlife tracking collars to monitor the movement of animals like deer, bears, and sea turtles. The antenna enables GPS positioning and LoRa data transmission, even when the collar is submerged (e.g., a sea turtle diving into the ocean) or exposed to rain. For example, researchers tracking sea turtles in the Great Barrier Reef use collars with IP68-rated antennas to collect data on migration patterns, helping to protect critical nesting habitats.

5.1.2 Marine and Maritime Industries

The marine industry is a major adopter of these antennas, as saltwater, heavy rain, and constant humidity make standard antennas impractical.

Marine GPS and Navigation Systems: Boats, ships, and yachts use waterproof active ceramic patch antennas for GPS positioning and chartplotting. These antennas maintain sub-5-meter accuracy even in rough seas, where saltwater spray and rain would corrode standard antennas. For example, a small fishing boat equipped with an IP68-rated GPS antenna can navigate safely through fog and storms, avoiding reefs and other hazards. The antenna’s compact size allows it to be mounted on the boat’s dashboard or mast without adding bulk.

AIS (Automatic Identification System) Transponders: AIS transponders use these antennas to transmit and receive vessel identification, position, and speed data—critical for collision avoidance in busy waterways (e.g., ports, straits). The antenna’s waterproof housing ensures reliable operation in saltwater environments, and its multi-band support (VHF 156-174 MHz + GPS L1) reduces the number of antennas needed on the vessel. For example, a cargo ship in the Suez Canal uses an AIS transponder with a waterproof active ceramic patch antenna to communicate with other ships and port authorities, ensuring safe passage through the narrow waterway.

5.1.3 Rugged Consumer Electronics

Rugged consumer devices—designed for outdoor activities or water-based sports—use these antennas to enable GPS tracking, Wi-Fi, and Bluetooth connectivity.

Outdoor Smartwatches and Fitness Trackers: Smartwatches like the Garmin Fenix 8 or Suunto 9 use waterproof active ceramic patch antennas for GPS tracking (running, hiking, swimming) and Bluetooth music streaming. The antenna’s IP68/IP69K rating ensures it survives swimming, showering, or exposure to rain, while its compact size (6mm×6mm×2mm) fits in the watch’s small casing. For example, a hiker using a Garmin Fenix 8 can track their route in a rainstorm, with the antenna maintaining GPS accuracy to within 3 meters.

Action Cameras and Drones: Action cameras (e.g., GoPro Hero 12) and consumer drones (e.g., DJI Mini 4 Pro) use these antennas for GPS positioning and Wi-Fi video transmission. The antenna’s waterproof housing protects it from water damage during water sports (e.g., surfing, snorkeling), and its low power consumption extends the device’s battery life. For example, a GoPro Hero 12 mounted on a surfboard can transmit live video to a smartphone via Wi-Fi, even when submerged in 10 meters of water, thanks to its IP68-rated antenna.

5.1.4 Industrial and Infrastructure Monitoring

Industries like oil and gas, construction, and utilities use these antennas to monitor critical infrastructure in harsh environments.

Pipeline and Utility Meter Monitoring: Sensors attached to oil/gas pipelines or water meters use waterproof active ceramic patch antennas to transmit data on pressure, flow rate, and leaks. These sensors operate in remote areas (e.g., deserts, wetlands) and are exposed to rain, snow, and mud. For example, a pipeline operator in Canada uses these sensors to monitor a 500km oil pipeline, detecting leaks within minutes and reducing environmental damage. The antenna’s IP68 rating ensures it survives sub-zero temperatures and heavy snowfall.

Construction Equipment Tracking: Construction companies use GPS trackers with these antennas to monitor the location and usage of equipment like excavators, bulldozers, and cranes. The antenna’s waterproof housing protects it from rain, dust, and construction debris, while its high sensitivity ensures it maintains positioning accuracy even in urban construction sites (where buildings block GPS signals). For example, a construction company in Dubai can track a fleet of bulldozers working on a skyscraper site, optimizing equipment usage and preventing theft.

5.2 Future Trends

5.2.1 Multi-Band and Multi-Constellation Support for Enhanced Connectivity

Future active ceramic patch antennas with waterproof housing will support an even wider range of frequency bands and GNSS constellations, enabling more versatile connectivity and higher positioning accuracy.

Expanded GNSS Support: Beyond GPS L1 and GLONASS G3, future antennas will support Galileo E5, BeiDou B2, and GPS L5—bands that offer better signal penetration (e.g., through foliage or buildings) and higher accuracy (sub-1-meter for GPS L5). This multi-constellation support will ensure reliable positioning even in weak-signal environments (e.g., dense forests or urban canyons). For example, a wildlife tracking collar with Galileo E5 support can track a bear in a dense pine forest, where GPS L1 signals are blocked by trees.

Dual-Band Wi-Fi and Cellular Support: Antennas will integrate support for Wi-Fi 6E (2.4/5/6 GHz) and 5G NR (New Radio) bands, enabling faster data transmission for outdoor IoT sensors. For example, a smart agriculture sensor with 5G NR support can transmit high-resolution crop health images to a cloud platform in real time, allowing farmers to make immediate decisions about pest control or irrigation.

This expanded band support will be enabled by advanced patch designs (e.g., multi-layer patches with slots for multiple frequencies) and wideband LNAs (which can amplify signals across 1-6 GHz), while maintaining the antenna’s compact size and waterproofing.

5.2.2 Miniaturization with MEMS Technology for Ultra-Small Devices

Micro-Electro-Mechanical Systems (MEMS) technology will drive further miniaturization of these antennas, making them suitable for even smaller devices—such as tiny IoT sensors, implantable medical devices, and smart contact lenses.

MEMS-Based Patch Radiators: MEMS fabrication techniques will enable the creation of ultra-small ceramic patches (2mm×2mm×0.5mm) by depositing thin layers of ceramic (1-10 micrometers) on a silicon substrate. These patches will maintain high gain (1-3 dBi) despite their size, thanks to advanced material engineering (e.g., nano-composite ceramics with high εr and low tanδ).

Integrated MEMS LNAs and Filters: MEMS technology will also enable the integration of ultra-small LNAs and filters onto the same silicon substrate as the patch, creating a “system-on-chip” (SoC) antenna. These SoC antennas will be 50-70% smaller than current designs (e.g., 3mm×3mm×1mm) and consume less power (2-5 mA), making them ideal for tiny IoT sensors (e.g., dust-sized environmental monitors) or implantable medical devices (e.g., glucose sensors for diabetics).

For example, a MEMS-based waterproof active ceramic patch antenna could be embedded in a smart contact lens to monitor intraocular pressure (for glaucoma patients) and transmit data wirelessly to a smartphone—all while being small enough to fit comfortably in the eye and waterproof to withstand tears.

5.2.3 AI-Powered Adaptive Performance Optimization

Artificial Intelligence (AI) will be integrated into these antennas to enable real-time performance optimization, addressing challenges like temperature sensitivity, interference, and signal weakening.

Dynamic Frequency Tuning: An AI algorithm running on a low-power microcontroller will monitor the antenna’s resonant frequency (via a built-in frequency sensor) and adjust the matching network (using a MEMS varactor) to compensate for temperature-induced shifts. For example, in a desert environment where temperatures swing from 10°C to 50°C, the AI will adjust the varactor’s capacitance to keep the patch’s resonant frequency within the GPS L1 band, maintaining full gain.

Interference Mitigation: The AI will analyze incoming signals to detect and filter out interference from Wi-Fi, cellular, or industrial equipment. If a strong 2.4 GHz Wi-Fi signal is detected, the AI will adjust the band-pass filter’s bandwidth to block the interference while preserving the target signal (e.g., GPS L1). This will ensure reliable performance in dense wireless environments (e.g., smart cities or industrial facilities).

Predictive Maintenance: The AI will track the antenna’s performance over time (e.g., gain, noise figure, seal integrity) and predict when maintenance is needed (e.g., a failing cable gland seal). For example, in a marine GPS antenna, the AI will alert the boat operator if the seal’s integrity degrades, preventing saltwater ingress and costly repairs.

5.2.4 Sustainable and Eco-Friendly Designs

As global focus on sustainability grows, future active ceramic patch antennas with waterproof housing will adopt eco-friendly materials and manufacturing processes to reduce their environmental impact.

Recyclable Materials: Housing materials will shift from non-recyclable plastics (e.g., PC) to recyclable or biodegradable alternatives (e.g., PLA-based polymers or recycled ABS). Ceramic substrates will use recycled alumina or barium titanate, reducing the need for virgin raw materials.

Energy-Efficient Manufacturing: Manufacturing processes like sputtering (for patch deposition) and injection molding (for housing) will be optimized to reduce energy consumption. For example, low-temperature sputtering (200°C vs. 400°C) will cut energy use by 30% while maintaining patch quality.

Energy Harvesting Integration: Antennas will integrate small energy harvesting modules (e.g., solar cells or vibration harvesters) to power the LNA and AI microcontroller, eliminating the need for disposable batteries. For example, a pipeline sensor with a solar-powered antenna can operate indefinitely in sunny areas, reducing waste from battery replacements.

6. Conclusion

Active ceramic patch antennas with waterproof housing represent a critical innovation in wireless communication and positioning, bridging the gap between compact, high-performance active antennas and rugged environmental resistance. Their unique combination of ultra-compact size (8mm×8mm×3mm to 15mm×15mm×5mm), low power consumption (5-15 mA), high RF performance (gain 1-5 dBi, NF 0.8-1.5 dB), and robust waterproofing (IP67/IP68/IP69K) makes them indispensable for industries ranging from outdoor IoT and smart agriculture to marine navigation and rugged consumer electronics.

As we have explored, these antennas overcome the limitations of standard active ceramic patch antennas—protecting internal components from moisture, dust, and saltwater while maintaining reliable signal performance. They enable wireless connectivity in environments that were previously inaccessible, from rain-soaked crop fields to deep-sea marine vessels, and their compact size allows integration into the smallest devices, from smartwatches to tiny IoT sensors.

While challenges remain—higher cost compared to non-waterproof antennas, signal loss in extreme configurations, mechanical fragility, and temperature sensitivity—manufacturers are addressing these issues through innovations like low-cost housing designs, MEMS miniaturization, and AI-powered adaptive tuning. These advancements will only increase the antenna’s versatility and accessibility, making it a staple in future wireless systems.

Looking ahead, the future of active ceramic patch antennas with waterproof housing is defined by multi-band connectivity, ultra-miniaturization, AI optimization, and sustainability. These trends will expand their applications to new frontiers—from implantable medical devices to smart city infrastructure—and ensure they play a key role in the next generation of wireless technology. Whether enabling precision agriculture in remote fields, guiding ships through stormy seas, or tracking athletes in extreme sports, these antennas will continue to be a critical enabler of reliable, ubiquitous wireless connectivity in the harshest environments.

In conclusion, active ceramic patch antennas with waterproof housing are more than just components—they are a catalyst for innovation in industries that demand resilience and performance. As technology evolves, they will remain at the forefront of wireless design, helping to build a more connected, efficient, and sustainable world.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)