Future Trends

1. AI-Enhanced Signal Processing

Future active antennas may integrate machine learning algorithms to detect and mitigate interference in real time. By analyzing signal patterns, these systems could dynamically adjust filtering or gain settings to maintain optimal reception in complex RF environments.

2. Multi-Antenna Arrays and Beamforming

Instead of a single patch, future surveying drones may use arrays of ceramic patches with beamforming capabilities. This would allow the antenna to electronically steer its reception pattern toward stronger satellite signals or null out sources of interference, significantly improving reliability in urban or forested areas.

3. Integration with Inertial Navigation Systems (INS)

Tighter fusion between GNSS antennas and high-grade MEMS or fiber-optic gyroscopes will enable robust navigation during signal outages (e.g., flying under bridges or tree canopies). The stable phase center of ceramic patches enhances the accuracy of such GNSS/INS integration.

4. Miniaturization and Conformal Designs

Advances in ceramic materials and 3D printing may lead to ultra-thin, flexible, or conformal antennas that can be embedded into drone fuselages or wings without compromising aerodynamics or aesthetics.

5. Enhanced Multi-Frequency Support

As new GNSS signals become available (e.g., GPS L6, Galileo E6), active ceramic antennas will evolve to support additional bands, enabling even more robust ionospheric correction and faster ambiguity resolution.

6. Quantum-Inspired Positioning Assistance

While still in research, quantum accelerometers and gravimeters may one day complement GNSS. High-stability active antennas will remain essential for aligning and calibrating these next-generation sensors.

7. Autonomous and BVLOS Operations

For drones flying Beyond Visual Line of Sight (BVLOS), precise and reliable positioning is a regulatory requirement. Active ceramic patch antennas will be critical in enabling safe, autonomous survey missions over large areas.

8. Onboard Edge Processing

Future antennas may include embedded processors that perform real-time signal quality assessment, health monitoring, and data preprocessing, reducing latency and bandwidth requirements.

9. Sustainable Materials and Manufacturing

There is growing interest in eco-friendly ceramic formulations and energy-efficient amplifier designs to reduce the environmental footprint of drone systems.

10. Standardization and Calibration Services

As demand grows, standardized phase center calibration databases and over-the-air testing protocols will emerge, ensuring consistent performance across different manufacturers and models.

These trends point toward a future where active ceramic patch antennas are not just passive signal receivers, but intelligent, adaptive components of a fully integrated navigation ecosystem. Their evolution will parallel advancements in drone autonomy, AI-driven data analysis, and global geospatial infrastructure.

6. Conclusion

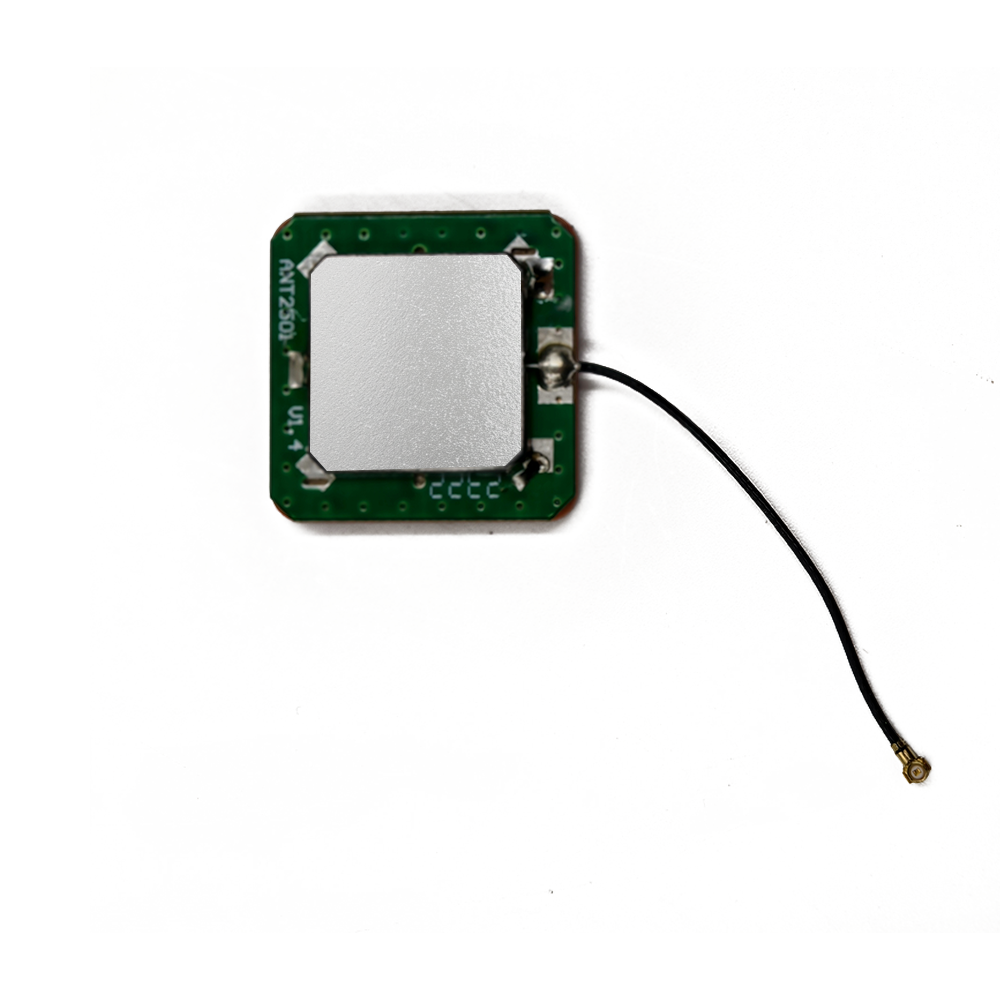

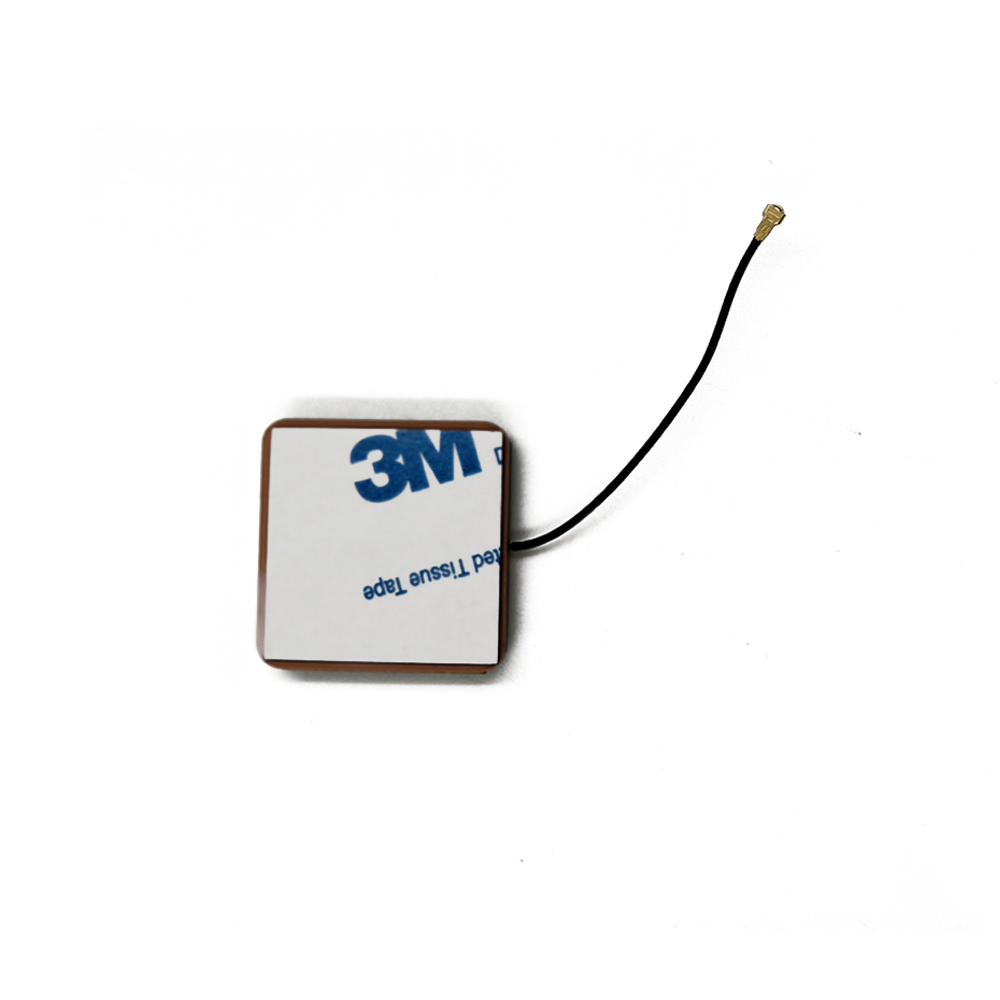

Active ceramic patch antennas have become an indispensable technology in the field of drone-based surveying, serving as the cornerstone of high-precision geospatial data collection. By combining the inherent advantages of high-dielectric ceramic materials with integrated low-noise amplification, these antennas deliver the signal fidelity, phase stability, and environmental resilience required for centimeter-level positioning accuracy.

Their compact size, multi-band capability, and directional gain make them ideally suited for integration into modern surveying drones, which must operate efficiently in challenging environments ranging from dense urban canyons to remote mountainous regions. The ability to support Real-Time Kinematic (RTK) and Post-Processed Kinematic (PPK) techniques ensures that aerial imagery and LiDAR data are accurately georeferenced, enabling reliable outputs for mapping, construction, agriculture, and environmental monitoring.

While challenges such as power dependency, electromagnetic interference, and cost remain, ongoing advancements in materials science, microelectronics, and signal processing are steadily addressing these limitations. The integration of AI, beamforming, and multi-sensor fusion promises to elevate the performance of active antennas beyond current capabilities, transforming them from passive components into intelligent navigation nodes.

As the demand for accurate, timely, and scalable geospatial data continues to grow—driven by smart cities, climate monitoring, and autonomous systems—the role of active ceramic patch antennas will only become more critical. They represent not just a technological solution, but a foundational enabler of the digital transformation in surveying and earth observation.

In conclusion, the active ceramic patch antenna is more than a component; it is a key enabler of precision, reliability, and innovation in the rapidly evolving world of surveying drones. As drone technology advances toward full autonomy and global deployment, these antennas will remain at the forefront, ensuring that every pixel captured from the sky is precisely where it should be.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)