Applications

Weatherproof RTK ceramic patch antennas are deployed in environments where standard antennas would fail, enabling precise positioning in challenging conditions:

Offshore and Marine Operations: These antennas are used on drones, vessels, and offshore platforms to support tasks such as wind farm inspection, oil rig positioning, and coastal mapping. For example, a drone equipped with an IP68 antenna can inspect offshore wind turbine blades during storms, using RTK to maintain a safe distance while capturing high-resolution imagery. The antenna’s saltwater resistance ensures long-term reliability in marine environments.

Agriculture in Extreme Conditions: Mounted on tractors, harvesters, and drones, these antennas provide continuous guidance during rain, dust storms, or extreme temperatures. In regions with monsoon seasons, they enable farmers to plant crops precisely even during heavy rainfall, avoiding delays that could reduce yields. In desert agriculture, they withstand sandstorms and high temperatures, ensuring consistent performance during irrigation and harvesting.

Infrastructure Inspection in Harsh Climates: Bridges, dams, and pipelines in arctic, desert, or coastal regions are monitored using drones and robots equipped with weatherproof antennas. For example, a robot inspecting a pipeline in the Sahara Desert uses the antenna to navigate with centimeter accuracy, even in 50°C heat and sandstorms, ensuring precise mapping of corrosion or cracks.

Search and Rescue in Extreme Weather: Emergency response teams use drones and handheld devices with these antennas to locate survivors during hurricanes, blizzards, or floods. The antenna’s ability to operate in heavy rain or snow ensures that the drone can maintain RTK positioning, even in low-visibility conditions, accelerating rescue efforts.

Mining and Quarrying: In open-pit mines, where dust, vibration, and extreme temperatures are common, weatherproof antennas guide autonomous trucks and drilling equipment with centimeter accuracy. They withstand exposure to dust, water, and chemicals used in mining processes, ensuring uninterrupted operation and reducing downtime.

Future Trends

The development of weatherproof RTK ceramic patch antennas is driven by advances in materials science, sensor integration, and environmental engineering:

Nano-Coatings for Enhanced Protection: Next-generation antennas will use superhydrophobic and oleophobic nanocoatings (e.g., graphene-based films) that repel water, oil, and dust more effectively than traditional materials. These coatings will reduce signal attenuation by minimizing surface buildup and allow for even thinner housing materials, improving gain.

Smart Thermal Regulation: Integrated sensors and phase-change materials will enable passive thermal management, absorbing excess heat in high temperatures and releasing it in cold conditions. This will stabilize the antenna’s operating temperature, reducing frequency shifts and improving performance across extreme ranges.

Wireless Power and Data Transmission: Future models may integrate wireless charging and Bluetooth/LoRa communication, eliminating the need for cables and connectors that can be points of failure. This will simplify installation and reduce vulnerabilities to moisture ingress, while maintaining weather resistance.

AI-Driven Performance Optimization: Antennas paired with AI-enabled receivers will adapt to environmental conditions in real time, adjusting gain, filtering, and RTK correction parameters to compensate for weather-related signal degradation. For example, during heavy rain, the AI could prioritize stronger satellite signals and apply additional multipath corrections to maintain accuracy.

Biodegradable and Biodegradable and Eco-Friendly Materials: As sustainability becomes a priority, manufacturers will develop weatherproof antennas using biodegradable polymers and recycled metals. These materials will maintain ruggedness while reducing environmental impact, particularly in applications like agricultural sensors that are deployed in large numbers and may be left in the field.

Multi-Band Expansion for Emerging GNSS Systems: Future antennas will support new GNSS frequencies, such as Galileo E6 and BeiDou B3I, to enhance accuracy and redundancy. This expansion will ensure compatibility with next-generation satellite systems, enabling even more precise positioning in harsh environments as these constellations grow.

Conclusion

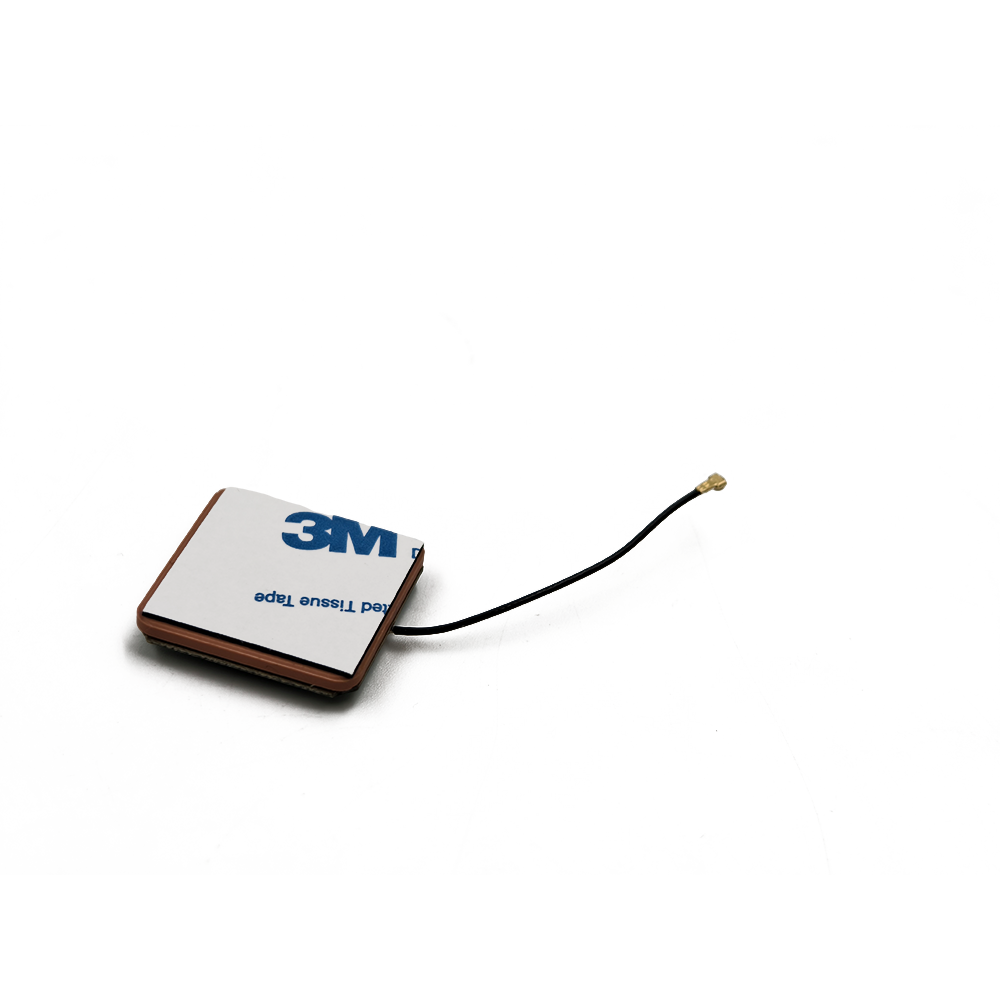

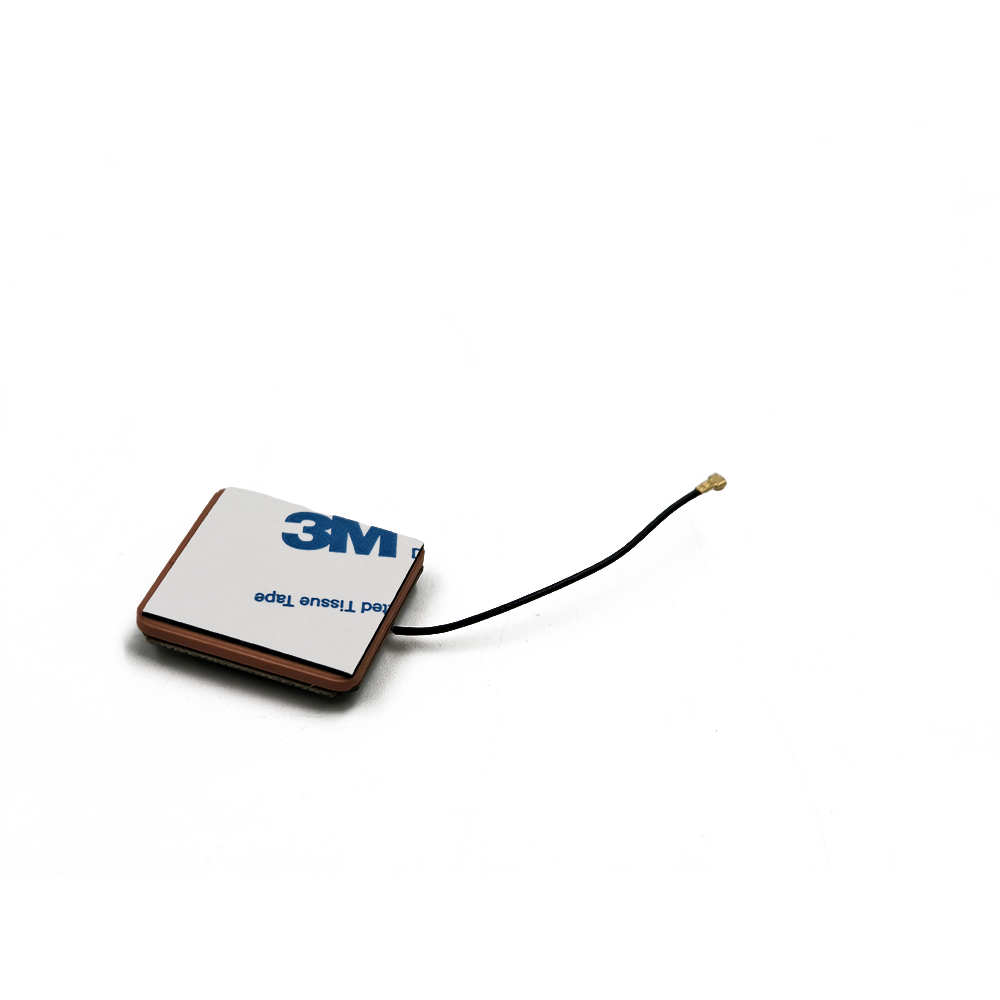

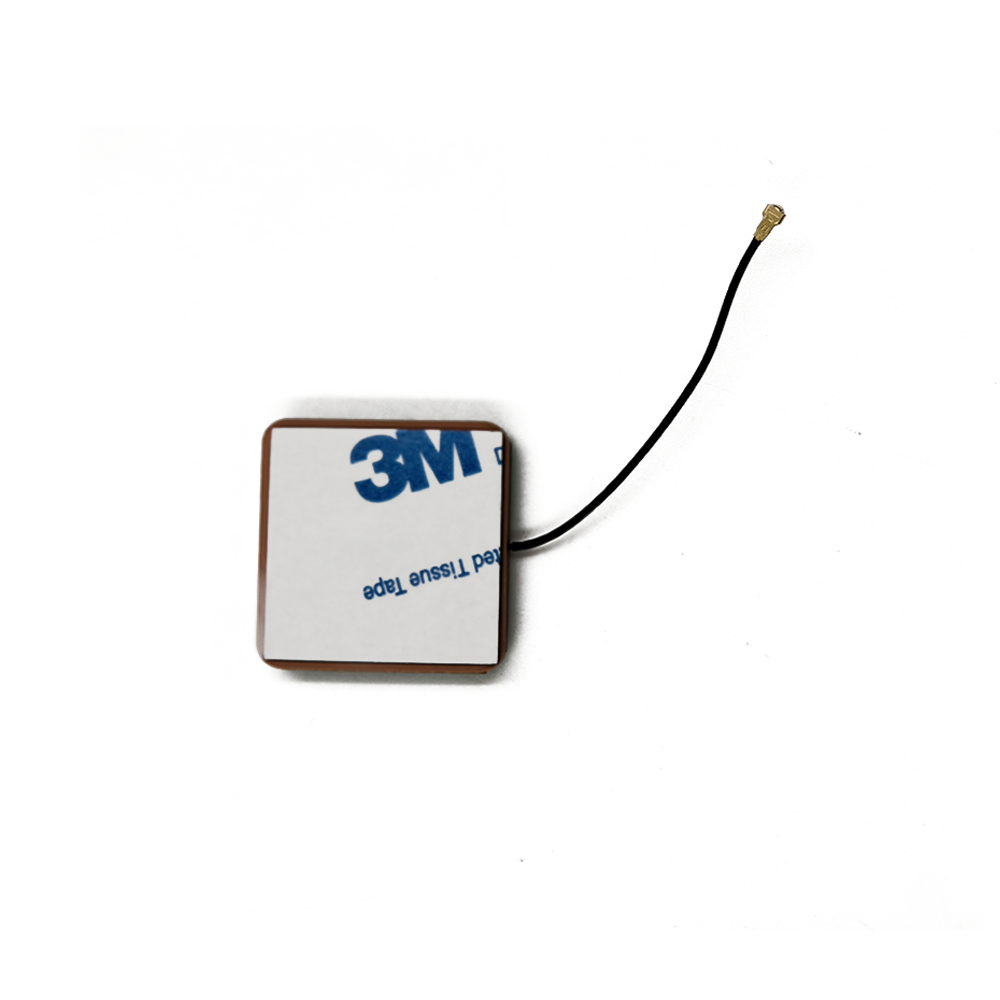

Weatherproof RTK ceramic patch antennas stand at the intersection of precision and durability, addressing the critical need for reliable high-accuracy positioning in the world’s harshest environments. By combining the compact efficiency of ceramic patch designs with robust weatherproofing—including hermetic sealing, thermally stable materials, and corrosion resistance—these antennas deliver centimeter-level RTK performance even in rain, snow, extreme temperatures, and saltwater exposure. Their ability to operate seamlessly across IP67 and IP68 standards has made them indispensable in industries ranging from offshore energy to emergency response, where weather-related downtime is costly or life-threatening.

The advantages of these antennas—uninterrupted operation in extreme conditions, reduced maintenance costs, and consistent data quality—far outweigh their challenges, such as higher upfront costs and minor gain reductions. As climate variability increases and field operations expand into more extreme territories, their role in enabling productivity and safety will only grow.

Looking ahead, innovations in nanocoatings, smart thermal regulation, and AI-driven optimization will further enhance their performance, making them smaller, more efficient, and more adaptable. The integration of eco-friendly materials will also align them with global sustainability goals, ensuring they remain relevant in an increasingly environmentally conscious market.

In essence, weatherproof RTK ceramic patch antennas are not just technical solutions—they are enablers of progress in harsh environments. Whether guiding a drone through a hurricane, monitoring a pipeline in the desert, or ensuring precise planting during monsoons, these antennas prove that precision and durability can coexist, pushing the boundaries of what is possible in geospatial technology.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)