OverView

A GPS RTK active antenna is a specialized type of GNSS (Global Navigation Satellite System) antenna. The "active" designation signifies that it incorporates a Low-Noise Amplifier (LNA) integrated directly into the antenna housing. This amplifier is crucial for boosting the incredibly weak signals received from GNSS satellites before they are sent through the coaxial cable to the receiver. Any loss in the cable attenuates both the signal and the noise equally; by amplifying the signal at the source (the antenna), the system maintains a favorable Signal-to-Noise Ratio (SNR), which is vital for the receiver to acquire and track satellites, especially for the precise carrier-phase measurements required for RTK.

The "waterproof" aspect, however, transcends a simple added feature; it is a fundamental design philosophy. These antennas are deployed in some of the most demanding environments on Earth. They are mounted on agricultural machinery, where they are subjected to relentless exposure to sun, rain, and chemical spray. They are fixed on marine vessels, constantly assaulted by saltwater spray and high humidity. They are used on construction sites, exposed to dust, debris, and downpours. In surveying, they might be placed in muddy fields or dropped into puddles. A standard consumer-grade antenna would succumb to these conditions in a short period, leading to system failure, downtime, and costly repairs.

The waterproof design ensures continuous operation through a multi-faceted approach to environmental protection. It is not merely about preventing liquid water from entering the housing. A truly robust design must also guard against:

Condensation: The ingress of humid air which can condense on internal electronics, causing short circuits and corrosion over time.

Dust and Particulates: Fine dust can infiltrate non-sealed units, coating circuits, and potentially causing overheating or electrical leakage.

UV Degradation: prolonged exposure to ultraviolet radiation from the sun can break down many plastics, making them brittle and prone to cracking.

Thermal Stress: Extreme temperature fluctuations cause materials to expand and contract, which can break seals and solder joints if not properly accounted for.

Physical Impact: Field use involves knocks, drops, and abrasion that the antenna must withstand.

To quantify and standardize this protection, the Ingress Protection (IP) rating system (defined by international standard IEC 60529) is used. The most common rating for professional-grade RTK antennas is IP67. Here, the '6' indicates complete protection against dust (dust-tight), and the '7' signifies protection against the effects of immersion in water between 15 centimeters and 1 meter for 30 minutes. Some military-spec or ultra-rugged antennas may achieve higher ratings like IP68 or IP69K.

Furthermore, for marine and coastal environments, resistance to salt fog corrosion is critical. This often involves using specific stainless-steel alloys for mounting hardware and specialized conformal coatings on internal circuit boards to protect them from the corrosive effects of salt.

In essence, a waterproof GPS RTK active antenna is a masterpiece of interdisciplinary engineering. It merges the precision of RF (Radio Frequency) design and electromagnetics with the practical disciplines of materials science, mechanical engineering, and industrial design. It represents a commitment to reliability, ensuring that the vital flow of satellite data—the lifeblood of any high-precision positioning system—remains uninterrupted, regardless of what the environment throws at it. This reliability is what allows industries to build automated and precision-critical processes around RTK technology, trusting that their "eye in the sky" will never be blinded by a storm.

Design and Construction

The creation of a waterproof GPS RTK active antenna is a meticulous process where electrical performance and environmental robustness are given equal priority. Every material, every seal, and every design decision is made to ensure the antenna performs flawlessly while enduring years of abuse. The construction is a layered approach, building protection from the inside out.

1. The Core Electrical Components:

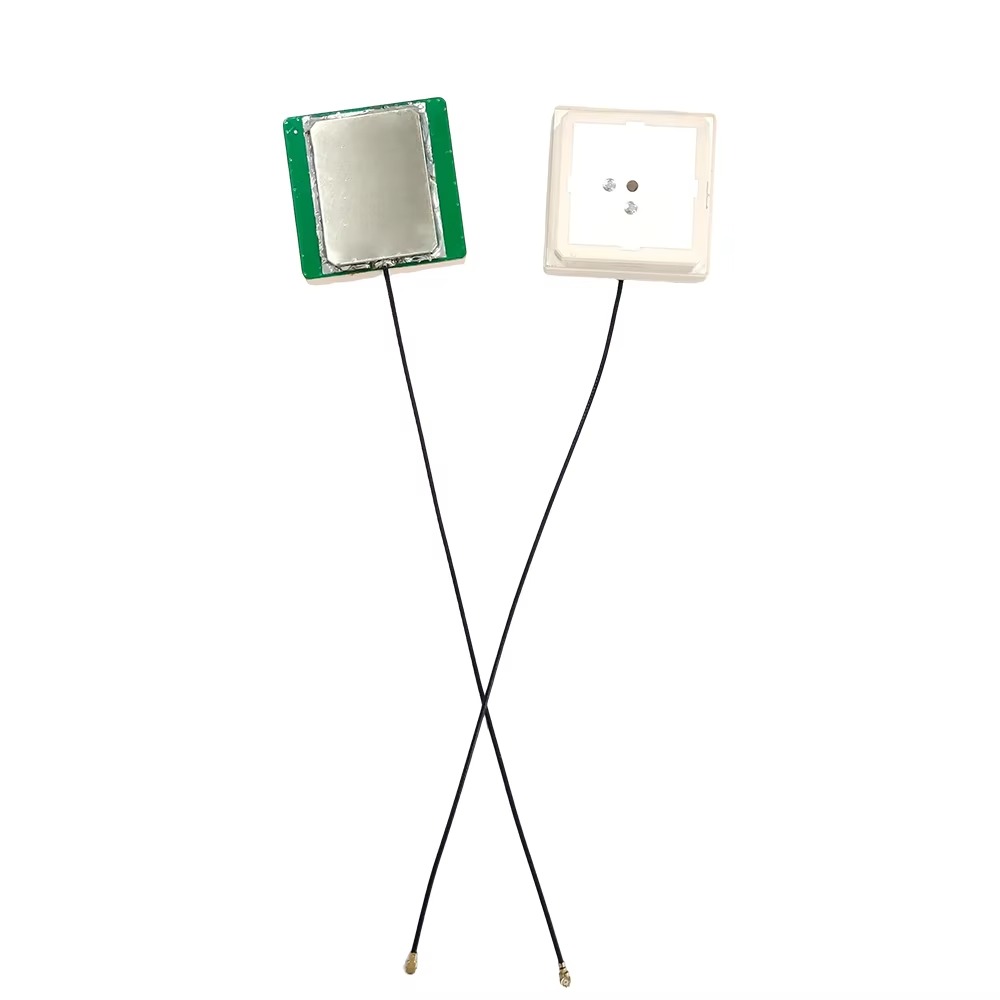

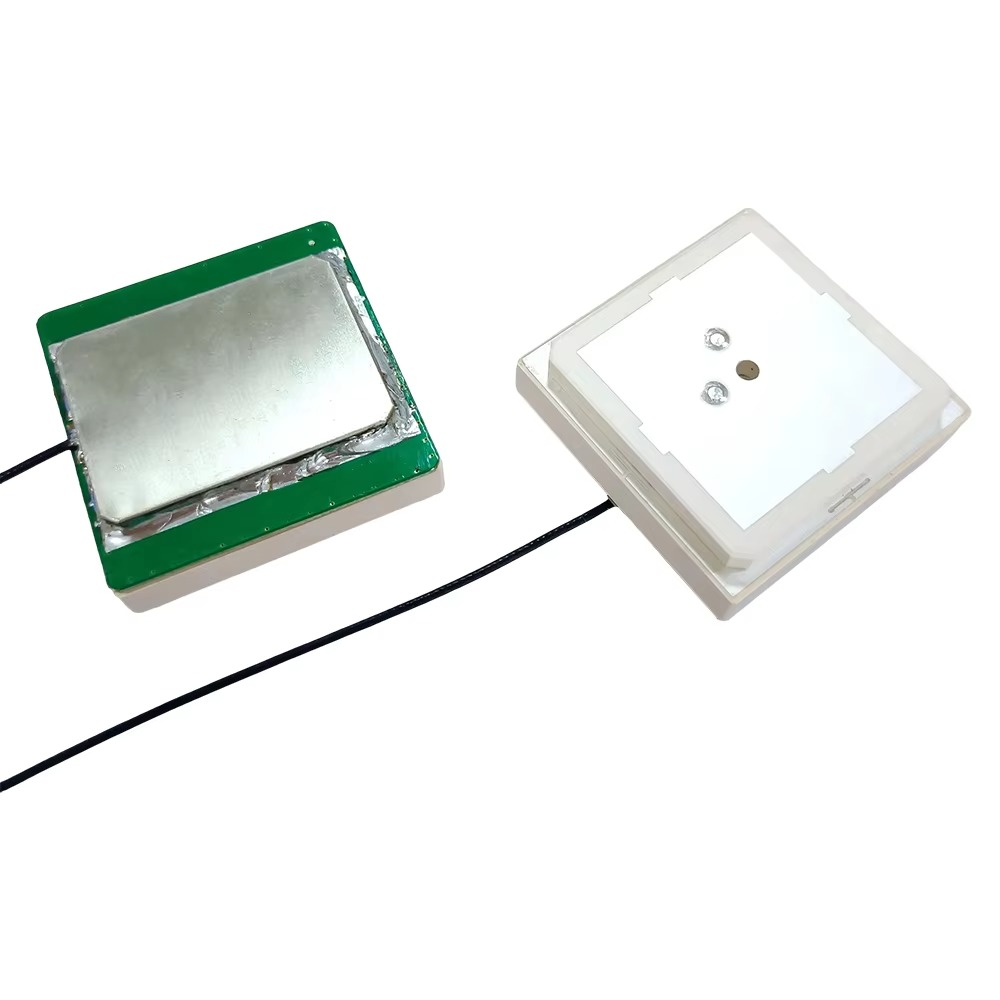

Radiating Element: This is the heart of the antenna, responsible for capturing the satellite signals. For RTK applications, a multi-frequency, multi-constellation (supporting GPS, GLONASS, Galileo, BeiDou) patch antenna is standard. This is typically a ceramic patch element, prized for its ability to be made small due to a high dielectric constant while maintaining good performance. The patch is meticulously designed for a stable phase center, low axial ratio (for good circular polarization), and a radiation pattern that maximizes gain towards the horizon and rejects signals from below (to mitigate multipath error).

Ground Plane: Beneath the radiating element lies a solid metal ground plane. This is crucial for defining the antenna's radiation pattern, directing energy upward, and providing a reference plane for the patch. Its size and quality directly impact the antenna's gain and front-to-back ratio.

Low-Noise Amplifier (LNA): This is the "active" part of the antenna. The LNA is mounted directly onto the RF feed line, immediately behind the radiating patch. Its purpose is to amplify the exceptionally weak satellite signals (often below the thermal noise floor) by typically 25 to 40 dB. This amplification is critical to overcome the signal loss in the coaxial cable that connects the antenna to the receiver. The LNA must be exceptionally low-noise itself; any noise it adds is amplified along with the signal, degrading the overall SNR. It is usually powered by a DC voltage (typically 3V to 5V) supplied to the antenna up the same coaxial cable from the receiver, a method known as "DC bias" or "phantom power."

2. The Layered Protection System:

Internal Conformal Coating: Once the patch, LNA, and associated circuitry are assembled on the substrate, the entire board is often treated with a conformal coating. This is a thin, protective polymeric film that is applied to insulate and protect the components from moisture, mild chemicals, dust, and temperature extremes. It prevents short circuits and corrosion, particularly from humidity that might slowly permeate even a sealed enclosure.

Environmental Sealing and Potting: For the highest levels of protection, the internal cavity is often filled with a potting compound. This is a thick, viscous material (like epoxy or silicone) that is poured in a liquid state and then cures into a solid or gel-like state. Potting provides superior defense against:

Water and Humidity: Creates a complete physical barrier.

Vibration and Shock: Encapsulates components, immobilizing them and preventing solder joints from cracking due to physical impact or constant vibration (e.g., on farm equipment).

Thermal Management: Some compounds are designed to help dissipate heat generated by the LNA.

The Radome: This is the external shell or dome that covers the entire antenna assembly. It is the first line of defense. Radome design is a critical compromise:

Material: Must be virtually transparent to RF signals at GNSS frequencies. Materials like polycarbonate, ABS, or ceramic-filled plastics are common. They must be chosen for UV stability to prevent yellowing and brittleness over time.

Shape: A dome shape is preferred as it sheds water easily and has no flat surfaces where water can pool. It also contributes to the antenna's mechanical strength.

Color: Light colors like white or light gray are standard to reflect solar radiation and minimize heat buildup, which can affect the LNA's performance and long-term reliability.

Seals and Gaskets: The interface between the radome and the baseplate is a critical failure point. A high-quality, compression o-ring gasket made of a durable elastomer like EPDM or silicone is used here. The baseplate is designed with a precise groove to compress this o-ring when the housing is screwed together, creating a water- and dust-tight seal. The cable entry point is another critical seal, often using a strain relief and a waterproof gland or compression fitting.

3. Mechanical and Mounting Design:

Baseplate: The bottom of the antenna is typically a metal baseplate (often aluminum) that provides structural rigidity, acts as part of the ground plane, and serves as a thermal mass to help dissipate heat. It features a standard mounting interface, most commonly a 5/8"-11 thread,

which is the industry standard for surveyor's poles, tripods, and vehicle mounts. Some antennas incorporate a magnetic mount for quick temporary placement on vehicle roofs.

Cable and Connector: The attached cable is itself a specialized component. It is a low-loss coaxial cable (e.g., LMR-type) to preserve the amplified signal. The outer jacket is thick, UV-resistant, and often made of materials like Polyurethane or TPE for flexibility in cold weather and resistance to abrasion, oils, and chemicals. The connector at the end (typically TNC, SMA, or N-type) is also chosen for its environmental resilience, often featuring a rubber boot for strain relief and a threaded coupling mechanism that is less likely to vibrate loose than a push-on connector.

In summary, the design and construction of a waterproof RTK antenna is an exercise in creating a hermetically sealed, electromagnetically optimized, and mechanically robust capsule. It is a device where every gram of potting compound and every millimeter of o-ring compression is calculated to ensure that the delicate process of capturing billionth-of-a-watt signals from space can continue uninterrupted in the harshest conditions on Earth.

Working Principles

The fundamental working principle of a waterproof GPS RTK active antenna is a seamless integration of electromagnetic wave reception, signal conditioning, and robust environmental protection. While the waterproofing is a passive mechanical feature, its presence is absolutely critical to maintaining the active electrical functions over time. The antenna's operation can be broken down into a sequential process from sky to cable.

1. Signal Capture and Initial Filtering:

The process begins with the radiating patch element. Engineered to resonate at the specific frequencies of GNSS signals (e.g., 1575.42 MHz for GPS L1, 1227.60 MHz for GPS L2), the patch acts as a transducer, converting the electromagnetic waves from the satellites into a tiny, oscillating electrical current on its feed point. The antenna's design ensures it is most sensitive to Right-Hand Circularly Polarized (RHCP) waves, which is the polarization used by GNSS satellites, and rejects reflected signals that may have become partially LHCP, thus providing innate multipath mitigation.

Simultaneously, the antenna's structure and the properties of the radome provide the first stage of filtering. The radome is designed to be transparent to the GNSS frequency band but will attenuate signals far outside this range. Furthermore, the antenna's ground plane and pattern reject signals arriving from below the horizon, minimizing interference from terrestrial sources.

2. Low-Noise Amplification (LNA): The "Active" Heart

The minuscule electrical current generated at the patch feed point is extraordinarily weak, often measured in picowatts. If this signal were sent directly down a several-meter-long cable to the receiver, the inherent loss (attenuation) of the cable would reduce it to a level indistinguishable from the thermal noise floor, making it impossible for the receiver to detect.

This is where the Low-Noise Amplifier (LNA) proves its indispensability. Located mere millimeters from the feed point, the LNA's primary job is to boost the amplitude of the received signal by a factor of 100 to 10,000 times (20 to 40 dB) before any significant loss can occur. The "Low-Noise" characteristic is paramount. Every electronic component generates a certain amount of noise. A poor-quality amplifier would add more noise than the gain it provides, drowning the signal in noise. The LNA in an RTK antenna is specifically selected and tuned for an exceptionally low Noise Figure (NF), typically around 1-2 dB, meaning it adds almost negligible noise of its own.

This pre-amplification is the single most important factor enabling the use of long cables between the antenna and the receiver without degrading system performance. It ensures that a strong, clean signal arrives at the receiver's front-end.

3. Power Delivery via DC Bias:

The LNA requires power to operate. Running a separate power wire to the antenna would compromise the waterproof seal and add complexity. The elegant solution is DC bias or phantom power. The GNSS receiver sends a low DC voltage (usually between 3 and 5 volts) up the center conductor of the very same coaxial cable that carries the amplified RF signal down to the receiver.

Inside the antenna, a simple circuit called a bias tee is used. It consists of inductors and capacitors that perform two functions:

It directs the incoming DC power from the cable to the LNA to power it.

It allows the amplified RF signal from the LNA to be coupled onto the cable without shorting out the DC power.

At the receiver end, another bias tee separates the DC power from the incoming RF signal, sending the RF signal to the processing circuitry.

4. The Role of Waterproofing in Upholding These Principles:

The waterproofing is not an electrical principle per se, but it is the guardian of all principles. Its function is to ensure the electrical characteristics remain stable and reliable over the product's lifetime.

Preventing Performance Drift: Moisture ingress on the PCB can change the dielectric constant around microstrip lines, altering the impedance matching and detuning the antenna and LNA. This would lead to increased VSWR (Voltage Standing Wave Ratio), signal loss, and degraded SNR.

Preventing Corrosion and Failure: Water, especially saltwater, causes rapid corrosion of the delicate metallic traces on the PCB, the solder joints, and the LNA itself. This would first increase electrical noise and eventually lead to a complete failure of the amplifier.

Maintaining Structural Integrity: The protection against physical shock and vibration ensures that the precise mechanical dimensions of the patch and its feed point remain unchanged. Any shift could alter the antenna's phase center stability—a critical parameter for RTK accuracy—and its resonant frequency.

Thermal Stability: The sealing and potting compounds help manage the thermal load from the LNA and from solar heating, preventing thermal cycling that could stress solder joints and cause them to fail over time (a phenomenon known as "thermal fatigue").

In essence, the working principle is a continuous cycle: capture weak signals, amplify them cleanly, and send them robustly to the receiver. The waterproof design ensures this cycle can repeat billions of times, in rain, dust, heat, and cold, without degradation, providing the receiver with a pristine signal from which it can derive its centimeter-accurate position.

Advantages and Challenges

-

The integration of robust environmental protection into a high-performance RTK antenna creates a product with compelling advantages that are essential for professional use. However, achieving this reliability introduces specific design and economic challenges that manufacturers must navigate.

Advantages:

Unmatched Reliability and Uptime: This is the paramount advantage. Waterproof antennas are designed for continuous, 24/7 operation in adverse conditions. This reliability translates directly to operational efficiency and cost savings by eliminating downtime due to weather-related equipment failure. A survey doesn't need to be halted for rain, and a farm tractor can operate in dew-soaked fields at dawn without concern.

Long-Term Performance Stability: Environmental protection is synonymous with performance stability. By preventing corrosion, moisture ingress, and UV degradation, the antenna's electrical parameters—gain, noise figure, axial ratio, phase center stability—remain consistent over years of use. This long-term stability is critical for scientific applications, permanent reference stations, and any project where data consistency over time is required.

Durability and Reduced Total Cost of Ownership (TCO): While the initial purchase price is higher than a non-ruggedized antenna, the waterproof antenna's longevity and resistance to failure lead to a lower TCO. It drastically reduces maintenance costs, replacement频率, and the risk of costly project delays. This makes it a financially sound investment for professional and industrial applications.

Versatility of Deployment: A single waterproof antenna model can be deployed across a vast range of applications without modification. It is equally at home on a surveyor's pole in a desert, on a fishing vessel in the North Atlantic, on a bulldozer on a construction site, or as a fixed base station on a roof. This versatility simplifies logistics for companies operating in multiple sectors.

Signal Integrity Assurance: The primary function of the active antenna is to deliver a high-fidelity signal. Waterproofing directly protects this function. By ensuring the LNA and its associated circuitry remain dry and corrosion-free, the antenna guarantees that the signal-to-noise ratio delivered to the receiver is always optimal, which is the foundation for achieving and maintaining a fixed RTK solution.

Challenges and Limitations:

Higher Unit Cost and Manufacturing Complexity: The addition of waterproof seals, high-quality radome materials, conformal coating, potting compounds, and rigorous testing inevitably increases the bill of materials and the complexity of the assembly process. This cost is passed on to the end-user. The potting process itself is a critical manufacturing step that must be precisely controlled to avoid introducing stresses or affecting RF performance.

Increased Weight and Size: The layers of protection, metal baseplate, and potting compound add significant mass and volume compared to a non-ruggedized antenna. This can be a consideration for applications where weight is a critical factor, such as on small drones or lightweight robotic platforms.

Thermal Management Challenges: While potting protects against the environment, it also acts as a thermal insulator. The LNA generates heat during operation, and this heat, combined with solar loading on a dark antenna, can cause internal temperatures to rise. High temperatures can slightly degrade the LNA's noise figure and, more importantly, long-term exposure to heat can reduce the lifespan of electronic components. Designers must carefully manage this through material selection and design to dissipate heat effectively.

Repair and Maintenance is Impossible: A truly potted and sealed antenna is essentially a "black box." If the internal electronics fail, the unit is not serviceable; it must be replaced entirely. This contrasts with some non-ruggedized systems where components might be replaced. This underscores the importance of extreme quality control during manufacturing.

Performance Trade-offs in Design: Every design decision is a compromise. A thicker, more robust radome might offer better protection but could introduce greater signal attenuation. Certain potting compounds can have dielectric properties that slightly detune the antenna if not accounted for in the initial design. The quest for absolute ruggedness can sometimes impose minor penalties on the absolute peak electrical performance achievable in a lab-grade, non-ruggedized unit.

Navigating the Trade-offs:

The market addresses these challenges through tiered product lines. Not every application requires the highest level of protection. Manufacturers offer:

Economy Models: May have a basic IP67 rating but use less potting or simpler seals for cost-sensitive applications where environmental exposure is moderate.

Professional Models: Feature full potting, high-quality materials, and rigorous testing for demanding daily use in all conditions. This is the core market for waterproof RTK antennas.

Marine & Geodetic Models: Represent the pinnacle, with enhanced corrosion resistance (e.g., stainless steel hardware), wider operating temperature ranges, and meticulously characterized phase center stability for the most critical applications.

The advantages of reliability, durability, and performance stability overwhelmingly outweigh the challenges for any professional user. The higher initial cost is rightly perceived as an insurance policy against the far greater costs of project failure, system downtime, and data corruption. The challenges are not roadblocks but rather engineering parameters that define the development of a product that is built not just to perform, but to endure.

Applications and Future Trends

-

The waterproof GPS RTK active antenna is not a niche product; it is the enabling sensor for high-precision positioning across the global economy. Its resilience allows it to be deployed in environments where standard electronics would fail, unlocking automation and data-driven precision in sectors that operate at the mercy of the elements.

Core Applications:

Precision Agriculture: This is one of the largest application areas. Waterproof antennas are mounted on the roofs of tractors, combines, and sprayers for RTK auto-guidance. They enable sub-inch pass-to-pass accuracy, eliminating overlaps and gaps in planting, fertilizing, and harvesting. This saves fuel, time, and inputs, boosting yield and profitability. Their ruggedness is essential for enduring dust, chemical spray, rain, and the constant vibration of farm machinery.

Marine and Hydrographic Survey: On boats, buoys, and unmanned surface vessels (USVs), these antennas provide precise positioning for charting, dredging, port construction, and underwater pipeline inspection. The waterproof rating is critical here, not just for rain but for constant saltwater spray and immersion-splash. corrosion resistance is equally important.

Construction and Machine Control: Bulldozers, graders, and excavators equipped with these antennas can grade land to precise design specifications without stakes. The antenna must survive the extreme vibration, dust, and occasional impacts of a construction site. Its reliability ensures that expensive machinery is not idle due to a failed sensor.

Surveying and Mapping: Surveyors rely on these antennas for all field work, whether in humid jungles, arid deserts, or urban settings. The antenna's phase center stability is as important as its waterproofing, as it directly impacts measurement accuracy. The ability to work in any weather keeps projects on schedule.

Fixed Infrastructure and CORS Networks: Continuously Operating Reference Station (CORS) networks form the backbone of modern positioning. Each base station uses a high-quality waterproof antenna installed on a permanent monument, often on a roof. These antennas operate unattended for years, enduring sun, rain, snow, and ice, and must provide exceptionally stable and reliable data 24/7.

Autonomous Vehicles and Robotics: From autonomous tractors and mining trucks to warehouse robots that venture outdoors, a reliable GNSS position is a fundamental source of truth. The waterproof antenna ensures this vital data stream is never interrupted by weather, enabling safe and continuous operation.

Future Trends:

Integration with Other Sensors ("Antenna+": The future is not just an antenna, but an integrated positioning hub. We will see more antennas with built-in Inertial Measurement Units (IMUs) and tilt sensors. This allows the antenna to provide not just position, but also precise heading, pitch, and roll, even when stationary—a feature known as GNSS Compass or Instantaneous RTK. This is invaluable for machine control and robotics. Further integration with cellular modems for correction streaming and UHF radios for base-rover links will create all-in-one solutions.

Advanced Materials and Miniaturization: Research into new radome materials that offer even better RF transparency and greater resistance to abrasion and UV will continue. The use of Metamaterials could lead to thinner, lighter, yet more robust designs. The drive for smaller, lighter antennas for drones and portable devices will continue without sacrificing durability.

Enhanced Cybersecurity for RTK Streams: As systems become more connected via NTRIP and other IP-based correction services, the antenna or its connected receiver will need to play a role in securing the data stream. We may see hardware-based encryption for correction data to prevent spoofing or malicious interference, which is a critical concern for autonomous systems.

AI-Enabled Performance Optimization: Future antennas could incorporate minimal processing power to self-monitor their health (LNA gain, noise figure) and signal environment. They could use basic AI algorithms to detect and filter out interference or multipath in the analog domain before it even reaches the receiver, providing an even cleaner signal.

Pervasive Use in the IoT: As the cost of high-precision GNSS continues to fall, waterproof antennas will become standard on a new class of Industrial Internet of Things (IIoT) devices. Imagine environmental sensors, wildlife trackers, or logistics tags that can report their location with centimeter accuracy, anywhere on the globe, in any weather.

The trajectory is clear: the waterproof RTK antenna will evolve from a standalone component into a smarter, more integrated, and even more resilient positioning node. It will remain the durable, reliable, and trusted workhorse on the front lines, capturing the signals from space that power the automated and precision-driven future of countless industries.

Conclusion

The waterproof GPS RTK active antenna is a paradigm of engineering where form and function are perfectly fused to meet the uncompromising demands of the real world. It stands as a critical testament to the principle that advanced technology must not only be high-performing but also profoundly reliable to deliver value in industrial and professional settings. It is the unsung hero of the high-precision positioning world, the robust and resilient sentinel that ensures the vital flow of satellite data remains constant, rain or shine.

Its significance lies in its role as an enabler. By providing a guaranteed, high-integrity signal in environments that would destroy lesser components, it allows industries to build complex, automated, and precision-critical systems with confidence. Farmers can automate their machinery, surveyors can trust their data in a downpour, and marine engineers can map the seabed with precision, all because they have a sensor they can depend on absolutely. This reliability is the foundation upon which the economic benefits of RTK technology—efficiency, reduced waste, accuracy, and automation—are built.

The journey of its design, from the electromagnetic purity of the ceramic patch to the brute-force environmental protection of the potting compound, is a story of thoughtful compromise. Engineers continually balance the quest for perfect electrical performance with the pragmatic needs of durability, cost, and manufacturability. The result is a product that may not always win on a single spec sheet metric in a lab but consistently wins in the far more important metric of field performance over time.

Looking forward, the waterproof antenna will not be made obsolete by new technologies; rather, it will evolve to incorporate them. The trends of sensor fusion, miniaturization, and increased connectivity will make it an even more intelligent and central component of the positioning system. Its core mandate, however, will remain unchanged: to capture the faintest whispers from space, amplify them with clarity, and protect this precious data stream from the elements with unwavering resolve.

In conclusion, the waterproof GPS RTK active antenna is far more than a simple accessory. It is a key pillar of modern precision technology. It represents a deep understanding that true sophistication in engineering is not just about achieving peak performance under ideal conditions, but about guaranteeing robust performance under the worst conditions. It is this rugged reliability, married to high precision, that transforms RTK from a laboratory curiosity into a powerful tool that is reshaping industries and paving the way for an autonomous future.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)