Overview

An RTK agricultural GNSS antenna is not a mere accessory; it is a high-precision sensor and the primary source of truth for a farm's automated operations. Its purpose is to provide a continuous, ultra-accurate, and reliable position and heading solution to the vehicle's guidance computer, which in turn controls the hydraulic or electric steering system to guide the tractor along pre-defined paths with sub-inch repeatability. This goes far beyond simple car navigation. We are not talking about meter-level accuracy from a standard GPS; we are talking about 1-2 centimeter (0.5-1 inch) accuracy in real-time, at speeds of up to 15-20 mph, across thousands of acres.

The system's functionality relies on a sophisticated setup. It is a two-part system consisting of a base station and a rover (the antenna on the tractor). The base station antenna is set up on a known, fixed point—often a permanent concrete pillar with precisely surveyed coordinates. Because its position is exactly known, it can calculate the error in the satellite signals it receives. It then broadcasts this error correction data via a radio link (typically UHF or 900MHz) or cellular network (NTRIP) to the rover antenna on the moving vehicle. The rover uses this local, hyper-accurate correction data to cancel out almost all atmospheric and orbital errors from its own GNSS calculations, achieving its legendary centimeter-level precision.

The value proposition of this technology is transformative. Before auto-steering, operators faced immense fatigue from manually steering to avoid overlaps and gaps, especially during long hours, in low-visibility conditions (dust, fog, night), or with wide implements. Human error was a significant source of input waste and yield loss. A mere 5% overlap in a fertilizer application across a 1,000-acre farm represents a massive and unnecessary expense. Conversely, a gap means lost yield potential.

The RTK antenna and auto-steering system eliminate this variability. They enable:

Input Savings: Precise application of seeds, fertilizers, and pesticides, eliminating overlaps and minimizing gaps.

Yield Optimization: Accurate planting and treatment ensure every plant has the space and nutrients it needs.

Reduced Operator Fatigue: The system handles the tedious task of steering, allowing the operator to focus on monitoring implement performance and machine health.

24/7 Operation: The ability to work through night, dust, and fog, maximizing the use of limited planting or harvesting windows.

Soil Conservation: Controlled Traffic Farming (CTF), where all machinery follows the same permanent tracks, becomes possible. This compactes only specific tramlines, leaving the crop zones undisturbed, improving soil health and water infiltration.

The agricultural RTK antenna itself is a product designed for a harsh environment. It must be robust enough to withstand constant vibration, extreme temperature swings, dust, moisture, and chemical exposure. Its design is a far cry from a consumer-grade GPS puck. It is a sophisticated instrument optimized for the L-band frequencies used by GNSS satellites, engineered to mitigate multipath error (signals bouncing off the tractor itself), and often equipped with tilt sensors to compensate for vehicle roll and pitch.

In essence, the RTK agricultural GNSS antenna is the cornerstone of the digital farm. It is the tool that translates satellite signals into actionable intelligence and physical action, transforming a tractor from a simple powered vehicle into an automated, data-generating, precision platform. It is the key that unlocks the economic and environmental benefits of precision agriculture, making farming more productive, sustainable, and profitable.

Design and Construction

The design and construction of an agricultural GNSS antenna is a study in engineering for extreme reliability and performance under duress. Every aspect, from the internal components to the external housing, is chosen to withstand the agricultural environment while delivering pristine signal reception.

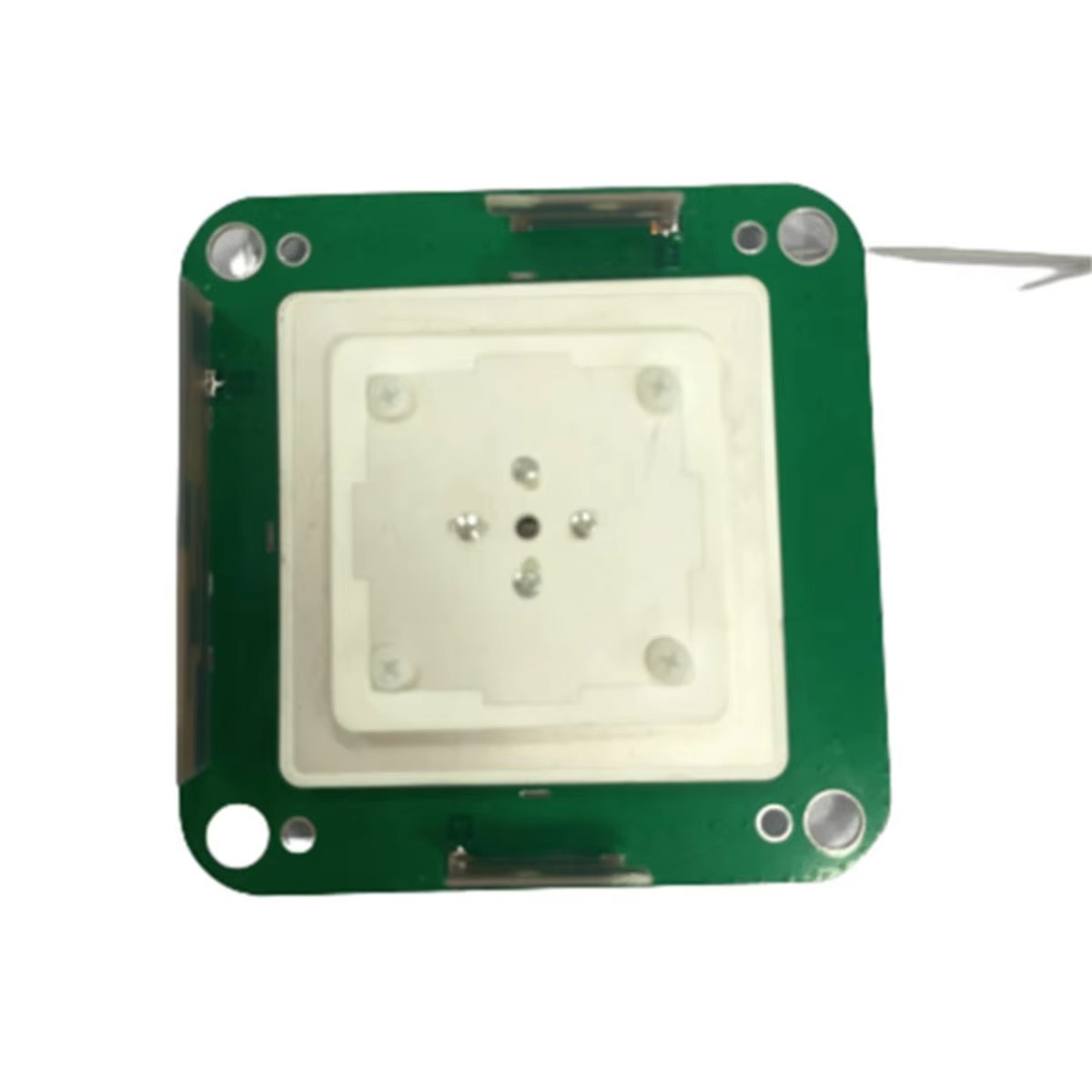

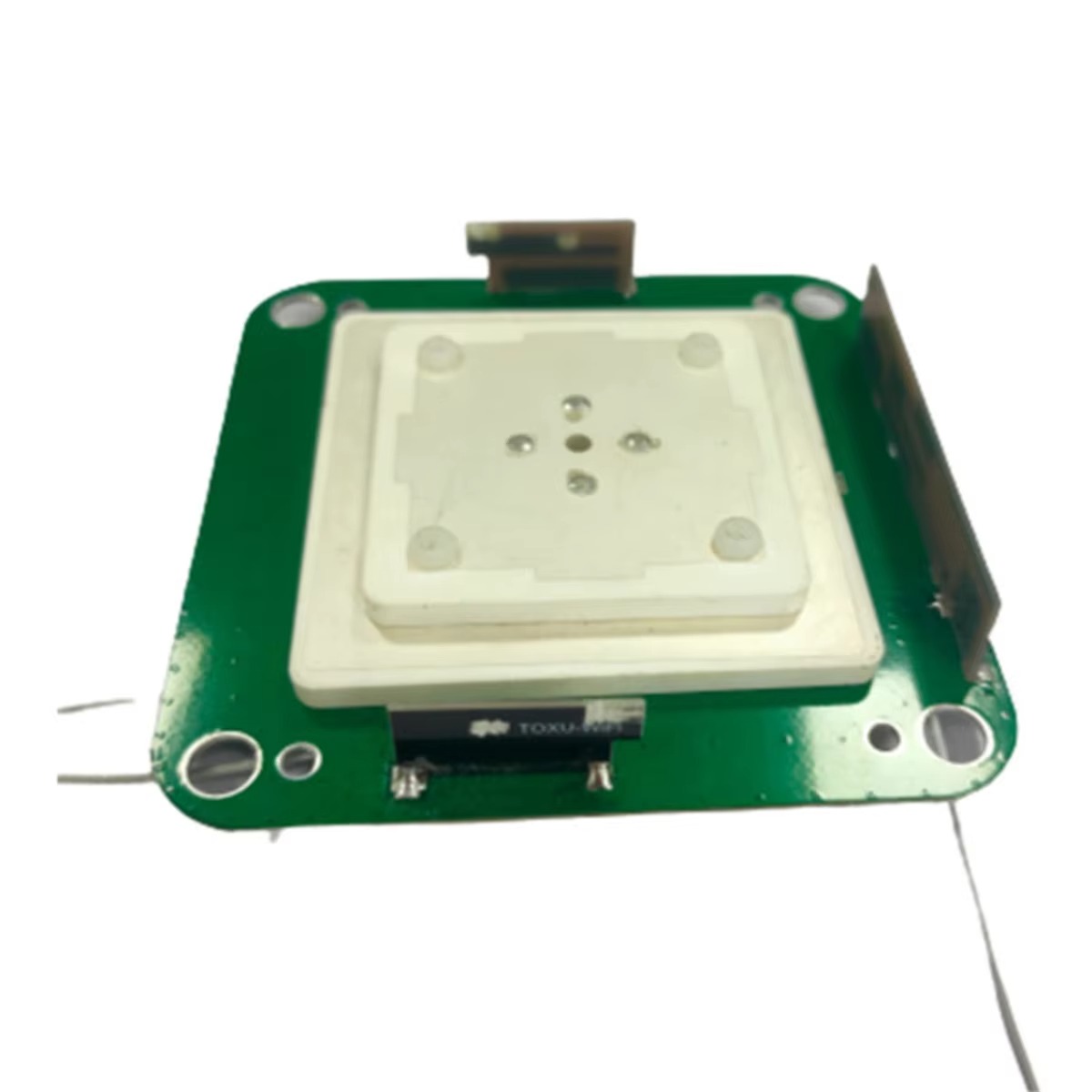

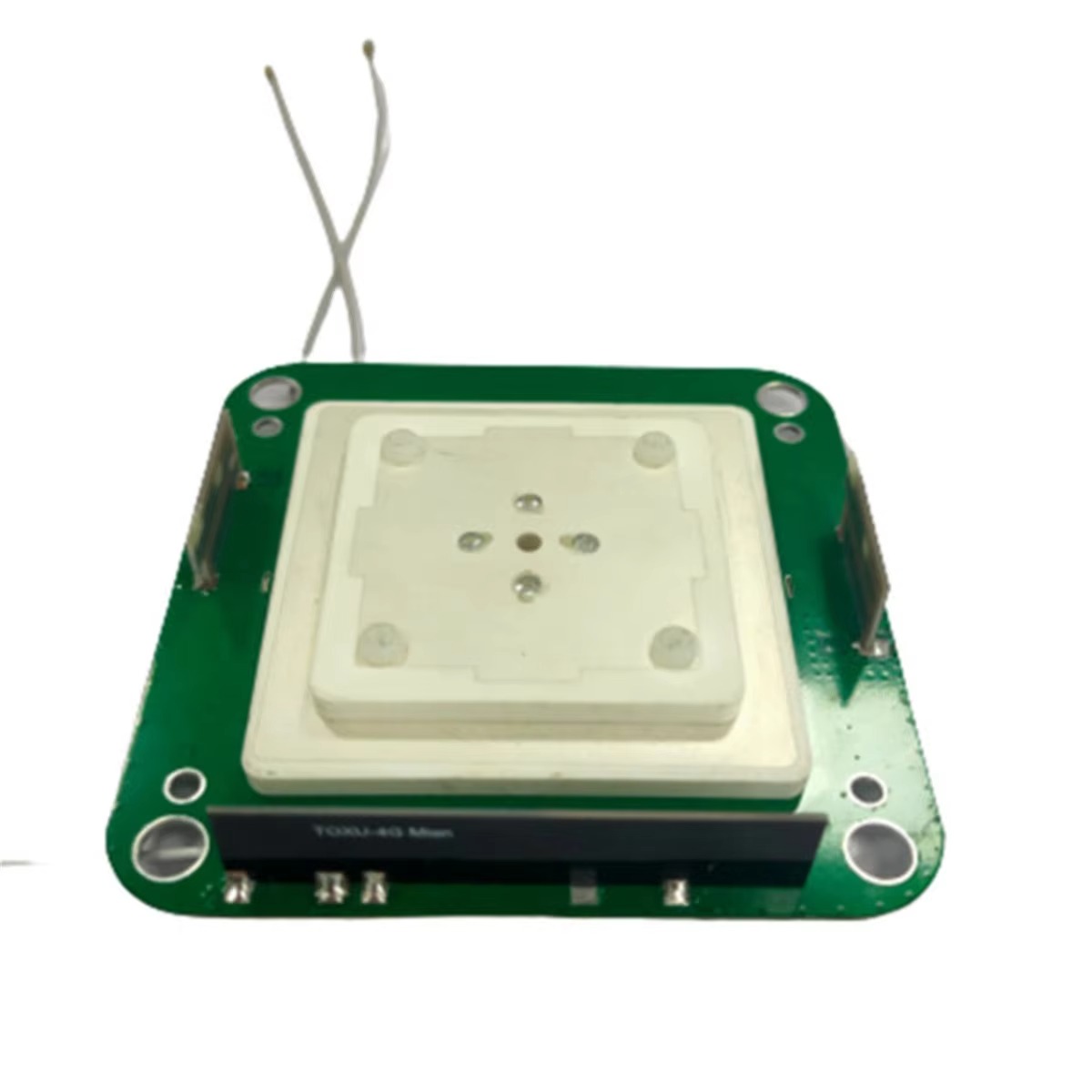

1. Radiating Element: The Heart of the System:

The core of the antenna is the element that actually captures the radio waves from satellites. Most high-precision agricultural antennas use a patch antenna design.

Material and Design: The patch is typically a ceramic substrate with a metal radiating element etched onto it. The ceramic has a high dielectric constant, allowing the antenna to be made physically small while remaining electrically tuned to the GNSS frequencies (e.g., L1 at 1575.42 MHz, L2 at 1227.60 MHz, L5 at 1176.45 MHz).

Polarization: GNSS satellites transmit Right-Hand Circularly Polarized (RHCP) signals. The patch antenna is specifically designed to be sensitive only to RHCP waves, which provides a significant advantage: it naturally rejects reflected signals. When a RHCP signal bounces off a building, the ground, or the tractor itself, its polarization reverses to Left-Hand Circular Polarization (LHCP). The antenna is largely deaf to these multipath signals, which are a primary source of positional error.

2. Ground Plane:

A critical and often overlooked component is the ground plane, a conductive surface located beneath the radiating patch. Its size and quality are paramount. A proper ground plane:

Establishes a stable and well-defined phase center. This is the virtual point from which the signal appears to originate. For RTK-level accuracy, the phase center must remain consistent regardless of the angle from which the signal arrives. Any movement or instability of the phase center introduces error into the position calculation.

Shapes the antenna's radiation pattern, directing gain upwards towards the sky (where the satellites are) and reducing sensitivity to low-angle signals and noise originating from the horizon, which are often multipath reflections or interference.

In many agricultural antennas, the vehicle's roof itself can act as a ground plane, but dedicated antennas include their own integrated ground plane to ensure consistent performance regardless of the mounting surface.

3. Low-Noise Amplifier (LNA):

The signals from GNSS satellites are incredibly weak by the time they travel over 20,000 km to Earth. The LNA is the first active component in the chain, and its job is to amplify these faint signals without adding significant noise. A high-quality, low-noise figure LNA is essential for acquiring and tracking satellites, especially in obstructed views or under foliage. The LNA is typically located directly within the antenna housing to amplify the signal before any loss can occur in the coaxial cable running to the receiver.

4. Bandpass Filtering:

To prevent out-of-band interference from cellular networks, radio transmitters, and other machinery from overloading the sensitive receiver, a bandpass filter is integrated into the antenna. This filter allows only the specific GNSS frequencies (L1, L2, L5) to pass through, rejecting all other RF energy.

5. Ruggedized Enclosure and Radome:

The external housing is what makes an agricultural antenna "agricultural."

Radome: The top dome is made of a material that is virtually transparent to RF signals (low dielectric loss tangent), such as high-quality polycarbonate or ceramic-filled plastics. It must be resistant to UV degradation to prevent yellowing and weakening over years of sun exposure.

Housing: The base is typically made from robust, corrosion-resistant materials like die-cast aluminum or hardened plastics. It is sealed to a high Ingress Protection (IP) rating, such as IP67 or IP69K, meaning it is completely dust-tight and can withstand immersion in water and high-pressure, high-temperature jet washing.

Mounting and Cabling: The antenna is designed with robust mounting options (e.g., strong magnetic bases, bolt-through holes) to resist vibration and shock. The cable connection is a sealed, weatherproof port, often using TNC or SMA connectors, and the cable itself is reinforced to resist abrasion, chemicals (fuels, oils, fertilizers), and chewing by rodents.

This combination of high-electrical-performance internals and nearly indestructible externals creates a device capable of delivering continuous, precise positioning from the heart of a dust-choked harvest to the cab of a sprayer bouncing through a rough field.

Working Principles

The operation of an RTK system is a complex dance of physics, mathematics, and real-time data processing. The antenna's role is to capture the raw satellite signals with the highest possible fidelity, but the magic of achieving centimeter accuracy happens through the sophisticated RTK algorithm.

1. The Source of Error: Why Standard GPS Isn't Good Enough

A standard GNSS receiver can achieve 2-5 meter accuracy under good conditions. The errors that cause this imprecision are well-known:

Satellite Orbit and Clock Errors: slight inaccuracies in the broadcast satellite position and time.

Ionospheric and Tropospheric Delay: The atmosphere slows down the GNSS signals, introducing a variable delay.

Receiver Noise: Internal electronic noise in the receiver.

Multipath: Signals bouncing off surfaces before reaching the antenna.

RTK neutralizes almost all of these errors through a differential technique.

2. The Differential Principle: The Base and Rover

RTK is a differential GNSS technique. It requires two receivers: a base station and a rover (the antenna on the tractor).

The base station is set up on a precisely surveyed point whose coordinates are known to the centimeter.

Because its position is known, the base can calculate the exact error in the measured satellite ranges. It determines the difference between the mathematically calculated range (based on its known position and the satellite's position) and the actual measured range (based on the signal travel time).

This difference is the total error for each satellite at that specific location and time. This error signal is highly correlated over a local area (typically within 20-40 km).

3. The Correction Data Stream

The base station formats this error information into a standardized correction message (most commonly using the RTCM - Radio Technical Commission for Maritime Services protocol) and broadcasts it to the rover via a radio link (UHF) or cellular network (using the NTRIP protocol).

4. The Rover's Calculation: Carrier Phase Tracking

This is where the precision is born. The rover does not just use the correction data to adjust its basic position calculation. Instead, it performs carrier phase tracking.

The rover measures the phase of the carrier wave of the GNSS signal itself, not just the code modulated onto it. The wavelength of the GPS L1 carrier, for example, is only about 19 cm. By measuring the phase to a small fraction of a wavelength, incredibly precise range measurements are theoretically possible.

However, the carrier phase measurement is ambiguous—the rover can measure the fractional wavelength perfectly, but it does not know the integer number of full wavelengths between it and the satellite. This is the integer ambiguity problem.

Resolving this integer ambiguity is the key to RTK. The rover uses the correction data from the base station, which includes carrier phase measurements, to help resolve these integers. Using a complex process of statistical estimation (like Least Squares or Kalman Filtering), it searches for the integer values that, when applied, result in a consistent and precise position solution relative to the base station.

5. The Role of Multi-Band Signals

Resolving the integer ambiguity is faster and more reliable when using dual or triple-frequency signals. Each frequency is affected differently by the ionosphere. By comparing the phase measurements on L1, L2, and L5, the rover can directly calculate and remove the ionospheric delay, which is a major source of error and ambiguity. This allows the system to "fix" the integer solution—a state known as RTK Fixed—within seconds, even when first turned on (a feature known as instant re-convergence or "fast-on"). Without multi-band signals, this process can take minutes and is less reliable.

6. Output: A Centimeter-Accurate Vector

Once the integer ambiguities are resolved, the rover knows its precise position relative to the base station with an accuracy of ~1 cm + 1 ppm (part per million) of the baseline distance. This relative position vector is then added to the known absolute position of the base to give the rover's absolute position in your chosen coordinate system (e.g., LAT/LON or UTM) with centimeter accuracy.

This entire process—receiving signals, getting corrections, resolving integers, and calculating position—happens multiple times per second (e.g., 10-20 Hz). This high update rate is essential for auto-steering, as the guidance computer needs a continuous, real-time stream of highly accurate position and velocity data to make constant micro-adjustments to the vehicle's steering hydraulics, keeping it precisely on its intended path.

Advantages and Challenges

-

The implementation of RTK GNSS for auto-steering brings a powerful set of advantages that have revolutionized farm economics, but it is not without its significant challenges and costs.

Advantages:

Unmatched Accuracy and Repeatability: The primary advantage is sustained centimeter-level accuracy. This allows for precise operations like inter-row cultivation and the foundation for Controlled Traffic Farming (CTF), where equipment always travels on the same wheel tracks, drastically reducing soil compaction in crop zones.

Massive Input Savings: Eliminating overlaps in seeding, spraying, and fertilizing directly saves thousands of dollars in input costs annually. A 2-5% saving on inputs on a large farm pays for the technology very quickly.

Yield Increases: Avoiding gaps ensures complete coverage, maximizing yield potential. CTF improves soil health and water infiltration, leading to better crop growth and higher yields over time.

Operational Efficiency and Fatigue Reduction: Auto-steering allows operators to focus on monitoring implement performance and machine functions rather than straining to steer straight lines. This reduces mental and physical fatigue, increases productivity, and extends working hours into low-visibility conditions (night, dust, fog).

Data-Driven Farming: The precise paths logged by the system create as-applied maps, providing a digital record of exactly what was done where. This data is invaluable for analysis, reporting, and optimizing future practices.

Challenges:

High Initial Cost: An RTK system is a significant capital investment. This includes the cost of the base station ($10,000 - $20,000+), the rover antenna and receiver for each vehicle ($5,000 - $15,000+), and the auto-steering hydraulic kit ($10,000+ per vehicle). This high barrier to entry can be prohibitive for smaller operations.

System Complexity and Management: Farmers must become IT managers. The system involves configuring GNSS receivers, managing radio networks or cellular subscriptions for NTRIP, maintaining a base station (including power and lightning protection), and ensuring all firmware is up to date.

Reliance on Communication Link: The rover must continuously receive the correction data from the base. A lost radio signal or cellular dead spot will cause the rover to lose its RTK Fixed solution, reverting to a less accurate (decimeter or meter-level) mode, which may not be sufficient for accurate auto-steering, forcing the operator to take over.

Base Station Dependency: Operating your own base station requires a secure, permanent location with a clear view of the sky and a reliable power source. Alternatively, subscribing to a paid subscription service (e.g., Trimble RTX, John Deere StarFire) eliminates the need for a private base but introduces an ongoing annual fee and relies on the cellular network coverage of the service provider.

Multipath and Signal Obstruction: While the antenna is designed to mitigate it, severe multipath from large metal structures or operating near trees and buildings can still degrade performance and cause occasional accuracy drops.

Maintenance and Support: When a highly complex system fails, downtime during critical planting or harvest windows is extremely costly. Access to timely and knowledgeable technical support is essential.

The decision to adopt RTK auto-steering is an economic calculation where the substantial long-term savings and yield benefits must be weighed against the high upfront investment and operational complexity.

Applications and Future Trends

-

The application of RTK auto-steering has expanded far beyond simply driving straight lines on a large field. It is the foundational technology enabling a suite of advanced precision agriculture techniques.

Current Applications:

Auto-Steering for All Field Operations: Guidance for tillage, planting, spraying, fertilizing, and harvesting.

Section and Row Control: On planters and sprayers, individual row units or sections can be automatically turned on and off based on the RTK-derived position, preventing overlaps on point rows and irregular field edges. This saves seeds and chemicals.

Controlled Traffic Farming (CTF): The repeatability of RTK allows all equipment to use the same permanent traffic lanes year after year.

Land Leveling and Drainage: For laser-guided land leveling, an RTK-equipped scraper can operate without a laser, providing even greater precision over large areas for perfect water management.

Yield Mapping: Correlating ultra-precise position data with yield monitor data creates highly accurate yield maps, which are the basis for understanding field variability.

Future Trends:

Platforms and Automation: RTK is the primary positioning source for emerging agricultural robots and autonomous tractors. Its centimeter-level accuracy is non-negotiable for safe and effective unmanned operation.

Machine-to-Machine (M2M) Coordination: In the future, a "leader" tractor with an RTK receiver could be followed by an autonomous "follower" implement (e.g., a grain cart) that uses its own RTK system to precisely track the leader's path, a concept known as "follow-me" functionality.

Advanced IMU Integration: Tighter coupling of GNSS and Inertial Navigation Systems (INS) will provide even more robust positioning. During short GNSS outages (e.g., driving under a tree), the IMU will dead-reckon and maintain accuracy, providing uninterrupted steering.

Precision GNSS for Individual Elements: The next evolution is moving beyond vehicle guidance to implement control. Imagine a sprayer boom where each nozzle is individually controlled based on its precise RTK-derived position, or a planter that micro-adjusts seed depth based on real-time topography.

Consolidation and Cost Reduction: As technology matures, costs will gradually decrease, making the technology accessible to smaller farms. All-in-one units that combine the antenna, receiver, and IMU into a single, simpler package will lower the barrier to entry.

The future of agricultural RTK is about integration—merging precise positioning with other data layers (soil, crop, weather) and machine data to enable fully optimized, automated, and sustainable farming systems.

Conclusion

The RTK agricultural GNSS antenna is far more than a simple navigation device. It is a high-precision sensor that has fundamentally redefined the practices of modern farming. By providing a continuous, centimeter-accurate geospatial reference, it has become the unmovable foundation upon which the entire structure of precision agriculture is built.

It has transformed the role of the farmer from an operator to a manager, leveraging data and automation to make smarter decisions. The economic and environmental benefits—through massive input savings, yield optimization, soil conservation, and reduced fuel consumption—are undeniable and have proven the technology's return on investment time and again.

The challenges of cost and complexity are real but are being steadily eroded by technological advancement, market competition, and the growing availability of subscription-based correction services. The future trajectory points towards deeper integration, greater automation, and wider adoption.

From guiding a 500-horsepower tractor pulling a 60-foot planter to enabling a small, autonomous weeding robot, the principle remains the same: knowing exactly "where" with unwavering certainty. In the relentless pursuit of efficiency and sustainability required to feed the world, the RTK antenna stands as a critical enabler, ensuring that every action in the field is performed with purpose, precision, and profit. It is the silent, steadfast guide that helps agriculture navigate its future.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)