Overview

A low-cost passive GNSS ceramic antenna is a type of antenna designed for mass-market applications where performance requirements must be balanced against stringent constraints of size, cost, and power consumption. Its name defines its core characteristics:

Low-Cost: Priced from a few cents to a few dollars in high volume, this affordability is achieved through economies of scale, simplified design, standardized materials, and fully automated manufacturing processes. This makes GNSS technology viable for consumer goods and large-scale IoT deployments.

Passive: It contains no active electronic components, such as a Low-Noise Amplifier (LNA). It is a purely passive radiating element that does not require a power source. This simplifies integration and reduces bill-of-materials (BOM) cost but places a greater burden on the receiver's sensitivity and the system's design to overcome signal losses.

Ceramic: The antenna's core is a block of ceramic material with a high dielectric constant (εr). This property allows the antenna to be electrically large (resonant at GNSS frequencies) while being physically small, a crucial feature for modern compact devices.

GNSS: It is typically tuned to receive signals in the L1 band (1560-1610 MHz), which is common to all major constellations (GPS, Galileo, GLONASS, and BeiDou), providing broad compatibility.

The proliferation of these antennas is a direct consequence of the consumer electronics revolution. The demand for location-based services in smartphones, wearables, drones, and asset trackers necessitated an antenna that could be invisibly integrated inside a device's housing, manufactured by the millions, and added for mere pennies. Unlike their high-precision, survey-grade counterparts—which are large, expensive, actively amplified, and meticulously calibrated—these low-cost variants prioritize form factor and cost above ultimate performance.

However, this prioritization involves significant engineering trade-offs. The performance of a low-cost passive ceramic antenna is intrinsically and profoundly linked to its integration environment. Its efficiency, bandwidth, and radiation pattern are not solely determined by its own design but are co-designed by the printed circuit board (PCB) it is mounted on, the device's plastic casing, and the proximity of other components. A poorly implemented antenna can render a sensitive GNSS receiver practically useless, leading to long satellite acquisition times, frequent signal drop-outs, and inaccurate positioning.

Therefore, the "low-cost" aspect is somewhat misleading from a total system perspective. While the component itself is inexpensive, realizing its full potential often requires careful and sometimes expensive RF design expertise, including proper PCB layout, ground plane design, and impedance matching. It is a component that offers accessibility but demands knowledge to wield effectively.

In essence, the low-cost passive GNSS ceramic antenna is the unsung enabler of the located world. It is a triumph of materials science and mass manufacturing that has placed the power of global positioning into the palms of our hands and the fabric of our connected lives, representing a critical balance between performance, size, and economy.

Design and Construction

The design and construction of a low-cost passive GNSS ceramic antenna is a meticulous exercise in optimizing performance within brutally strict economic and physical constraints. Every material, manufacturing step, and design choice is scrutinized to shave fractions of a cent from the production cost while maintaining acceptable functionality.

1. The Ceramic Core: The Engine of Miniaturization

The foundation is a sintered ceramic block, typically composed of a titanium-based material (e.g., Barium Strontium Titanate). The single most important property of this ceramic is its high dielectric constant (εr or Dk), which usually ranges from 20 to 40 for these cost-optimized versions (higher-end materials can exceed 80). A high Dk is the key to miniaturization. The physical length required for an antenna to resonate at a specific frequency is inversely proportional to the square root of the Dk (λ = λ₀ / √εr). By using a high-Dk material, the wavelength within the ceramic is dramatically shortened, allowing the physical antenna size to be reduced to a small fraction of the free-space wavelength (~19 cm for a ¼ wave at 1.5 GHz), resulting in typical dimensions of just 10x10x3 mm or even smaller.

2. The Radiating Element: Printed Precision

The radiating element is not a separate piece of wire but a silver electrode pattern printed onto the surface of the ceramic block. The most common design is a variant of the Planar Inverted-F Antenna (PIFA). The PIFA is favored for its good compromise between size, bandwidth, and ease of impedance matching. Its key features include:

Radiating Plate: The main area that defines the resonant frequency.

Feed Point: The precise location where the signal is coupled to the PCB's transmission line via a solder pad.

Shorting Pin: A critical feature that connects the radiating plate to the ground plane. This pin lowers the antenna's resonant frequency and helps to match its impedance closer to the desired 50 ohms, reducing the complexity and cost of the external matching network.

The shape, length, and placement of this silver pattern are meticulously calculated through electromagnetic simulation software to achieve resonance in the GNSS L1 band.

3. Cost-Optimized Materials and Processes

The pursuit of low cost dictates every material choice:

Ceramic Material: While high-Dk is essential, the specific ceramic composition is chosen for its cost-effectiveness and ease of manufacturing rather than ultimate low-loss performance. The loss tangent (a measure of signal energy lost as heat) of these materials may be higher than that of premium ceramics.

Electrode Material: Silver paste is used for its excellent conductivity and suitability for screen printing and high-temperature firing processes.

Mass Production: The manufacturing process is highly automated. Ceramic sheets are printed with hundreds of electrode patterns, laminated, diced into individual units, fired in kilns, and then taped-and-reeled for use by automated pick-and-place machines. This scale is what drives the cost down to commodity levels.

4. The Indispensable Partner: The PCB Ground Plane

A low-cost passive ceramic antenna cannot function alone. It is designed to be used with a PCB ground plane, which becomes an integral part of the radiating system. The antenna element excites currents on the ground plane, which itself radiates. The size and quality of this ground plane are arguably more important to final performance than the antenna itself. Manufacturers always specify a minimum required ground plane area (e.g., 40x40 mm) that must be kept clear of components and signals on other layers. A undersized or poorly designed ground plane is the most common cause of antenna failure, rendering the component useless.

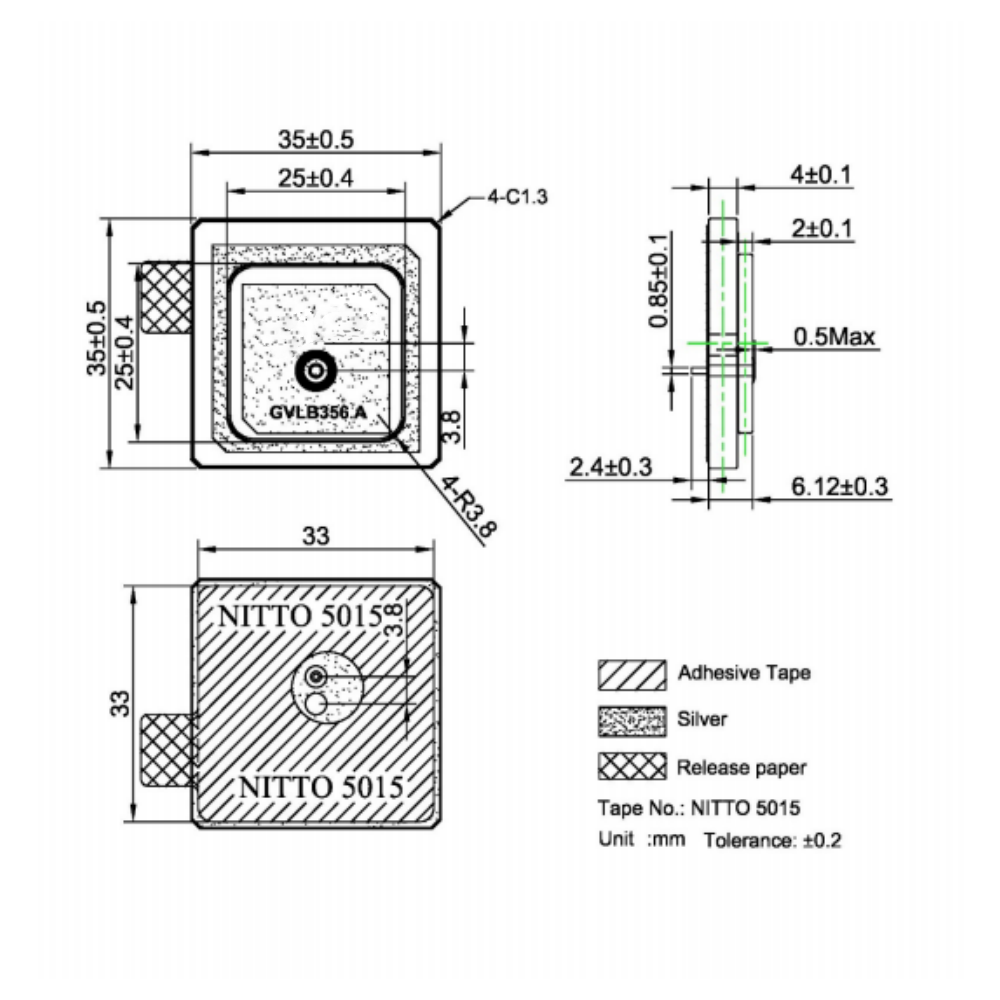

5. Construction for Assembly

The antenna is packaged as a standard Surface-Mount Device (SMD). The solder pads on the bottom are designed to create a small air gap between the antenna body and the PCB after reflow soldering. This air gap, with its lower dielectric constant than the PCB's FR4 substrate, is part of the antenna's designed operating environment. Soldering the entire base to the board would embed it in the FR4, detuning its frequency and degrading performance.

In summary, the construction of a low-cost antenna is a holistic process of creating a "performance engine" that is intentionally incomplete. Its final characteristics are co-designed by the host device's PCB, making the system integrator a crucial partner in its performance. The design choices are a constant balance between achieving acceptable RF performance and hitting an aggressive cost target that enables mass-market adoption.

Working Principles

The operation of a low-cost passive GNSS ceramic antenna is a delicate dance of resonance, energy transfer, and environmental interaction. Its task is to efficiently capture electromagnetic energy from satellites over 20,000 km away, where signal power is billions of times weaker than a mobile phone signal, and deliver it to the receiver with minimal loss.

1. Resonance: The Foundation of Reception

An antenna is fundamentally a resonant circuit. The ceramic PIFA is carefully dimensioned to be electrically resonant at the GNSS L1 frequency (~1575 MHz). At resonance, the antenna's impedance is purely resistive (ideally 50 ohms), and its reactance is zero. This is the condition for maximum power transfer from free space into the antenna's terminals. The high-dielectric ceramic enables this resonance to occur in a physically small structure by effectively "compressing" the electromagnetic wavelength.

2. The Symphony with the Ground Plane

The antenna does not operate in isolation. The currents on the ceramic element induce "image currents" on the PCB's ground plane. These currents cause the entire ground plane to radiate. Therefore, the complete antenna system is the combination of the ceramic chip and the PCB. The radiation pattern is not isotropic but is typically a distorted hemisphere, directed away from the ground plane. This is often beneficial, as it naturally directs energy toward the sky (where the satellites are) and away from the lossy components inside the device.

3. Impedance Matching: The Critical Handshake

For maximum power transfer, the impedance of the antenna system (element + ground plane) must match the impedance of the transmission line (the microstrip trace on the PCB) and the input of the GNSS receiver (50 ohms). While the PIFA's shorting pin helps, a perfect match is rarely achieved. Therefore, a matching network is essential.

This network is a simple circuit of passive components—usually one or two capacitors and inductors—placed on the PCB between the antenna and the receiver. This network transforms the antenna's complex impedance to as close to 50 ohms as possible. The design of this network is not generic; it must be customized for the final PCB layout and enclosure, as these factors significantly affect the antenna's impedance. Optimizing this match is the single most important step in ensuring good performance.

4. Balancing Bandwidth and Performance

GNSS signals themselves are narrow, but the antenna needs bandwidth to cover signals from multiple constellations (e.g., GPS L1 at 1575.42 MHz and Galileo E1 at 1575.42 MHz, with others nearby) and to account for manufacturing tolerances and environmental shifts (e.g., temperature change, proximity to plastic). However, small antennas have a high Q factor, which inherently limits their bandwidth. Designers work to achieve an adequate bandwidth (typically 10-20 MHz) while maintaining efficiency, often a challenging trade-off.

5. Efficiency: The Measure of Success

The ultimate metric of a passive antenna's performance is its radiation efficiency—the percentage of power accepted at its terminals that is actually radiated into space (or received from space). Efficiency is always less than 100% due to losses:

Dielectric Loss: Energy converted to heat within the ceramic material (higher in cost-optimized ceramics).

Conductor Loss: Resistance in the silver electrodes.

Ground Plane Loss: Imperfect conduction in the PCB copper.

Mismatch Loss: Power reflected back due to impedance mismatch.

Near-Field Loss: Energy absorbed by nearby components and materials (e.g., the battery, LCD screen, or device casing).

A well-integrated low-cost antenna might achieve 50-60% efficiency (-3 to -2.2 dB), meaning nearly half the signal is lost. A poor implementation can easily fall below 25% (-6 dB), crippling the receiver's ability to acquire and track satellites.

In essence, the antenna works by resonating in sympathy with the satellite signals. It captures their minuscule energy and, in concert with its ground plane, delivers that energy through a carefully tuned pathway to the receiver. The receiver's job is to amplify this weak signal and extract the data, but it can only work with what the antenna system provides. A weak, inefficient antenna forces the receiver to work at the very edge of its sensitivity, resulting in poor performance.

Advantages and Challenges

-

The decision to use a low-cost passive GNSS ceramic antenna is a fundamental engineering trade-off, offering compelling advantages for product design and economics while introducing significant technical challenges that must be meticulously managed.

Advantages:

Extremely Low Cost: This is the paramount advantage. Costing pennies in volume, it makes GNSS functionality economically viable for consumer products and large-scale IoT deployments where BOM cost is a primary driver.

Miniaturization: Its tiny form factor (often under 100 mm³) allows it to be integrated into the most space-constrained devices like wearables, trackers, and compact modules, enabling sleek product designs without external protrusions.

Ruggedness and Reliability: As a single, solid ceramic component soldered directly to the PCB, it is highly resistant to shock, vibration, corrosion, and physical wear. There are no cables to break or connectors to fail.

Ease of Manufacturing: Being a standard SMD component, it is perfectly suited for fully automated PCB assembly using pick-and-place machines and reflow ovens, eliminating manual steps and ensuring manufacturing consistency and scalability.

Zero Power Consumption: As a passive component, it requires no power supply, simplifying the overall system design and contributing to lower power consumption for battery-operated devices.

Design Flexibility: It can be hidden within the device's enclosure, granting industrial designers complete freedom over the product's aesthetic form.

Challenges:

Performance Entirely Dependent on Integration: This is the greatest challenge. The antenna's performance is not intrinsic; it is a product of its integration. The PCB layout, ground plane size and shape, component placement, and plastic housing all dramatically affect its efficiency and resonance. A perfect antenna can be ruined by a poor PCB design.

Lower Performance: Compared to an active external antenna, a passive internal antenna inherently has lower gain and efficiency due to its small size, higher-loss materials, and losses in the surrounding environment. This results in weaker signal reception, longer Time-To-First-Fix (TTFF), and poorer performance in challenging signal environments (urban canyons, under tree cover).

Sensitivity to the Human Body (Hand Effect): The human body is mostly water, which absorbs RF energy at GNSS frequencies. When a hand grips a device, it can block the antenna's radiation pattern, detune its resonant frequency, and drastically reduce its efficiency. This is a major design hurdle for smartphones and wearables.

Complex and Expertise-Driven Design Process: Successfully integrating one of these antennas requires significant RF expertise. It involves:

Careful PCB Stack-up Design: Ensuring continuous ground planes.

Strategic Placement: Locating the antenna in a corner or at the edge of the board, away from noise sources and large obstructive components like batteries and displays.

Mandatory Tuning: The matching network must be optimized on the final physical board with its enclosure installed. This requires access to a vector network analyzer (VNA) and RF engineering knowledge.

Susceptibility to Noise: Located on the main PCB, the antenna is vulnerable to noise from digital circuits (processors, memory), power supplies, and other radios (cellular, WiFi, Bluetooth). This noise can easily drown out the incredibly weak GNSS signals, necessitating careful board layout, filtering, and often shielding.

Narrow Bandwidth: It is challenging and expensive to design a very small, low-cost antenna that covers multiple GNSS bands (e.g., L1 and L5) effectively. Most are optimized solely for the L1 band.

In conclusion, the advantages of ultra-low cost and small size make these antennas the default choice for mass-market electronics. However, these benefits are not free; they are exchanged for a set of complex design challenges that require specialized knowledge to overcome. The "low-cost" component can often lead to "high-cost" design efforts.

Applications and Future Trends

-

The low-cost passive GNSS ceramic antenna is the linchpin of the mass-market location revolution, finding its way into a breathtaking array of devices. Its future evolution is shaped by the demands of these applications and the relentless push for better performance at lower cost.

Applications:

Smartphones and Tablets: The primary driver of volume. Nearly every smartphone on the market uses one or more of these antennas for GNSS, battling space constraints and the "hand effect" to provide adequate location services for navigation and apps.

Wearable Technology: Fitness trackers, smartwatches, and child monitors rely on these tiny antennas. This is perhaps the most challenging environment due to extreme miniaturization and the significant signal blockage and detuning caused by the human body.

Asset Tracking and IoT: A massive growth area. Small, low-power trackers for logistics, supply chain management, agricultural monitoring, and theft prevention use these antennas to report their position over cellular (LTE-M, NB-IoT) or other wireless networks.

Drones and Robotics: Consumer drones and small robotic platforms use these antennas for basic navigation and position holding, where their small size and weight are critical advantages.

In-Vehicle Telematics and UBI: Small dongles that plug into a car's OBD-II port for usage-based insurance (UBI) or fleet tracking areapplications, often leveraging the vehicle's exterior to get a better signal.

Consumer Electronics: Digital cameras (for geotagging photos), portable gaming devices, and personal navigation devices (PNDs) have historically been major users.

GNSS Modules: Many off-the-shelf GNSS receiver modules for developers come with a pre-integrated ceramic antenna, simplifying the design process for embedding GNSS into a final product.

Future Trends:

Improved Resilience to Detuning: A major focus is on designing antennas that are less sensitive to the effects of the human body and device casing. Techniques include:

Balanced Feed Designs: Using a differential feed to make the antenna less susceptible to near-field interference.

Reconfigurable Antennas: Using tunable components (like varactor diodes) to dynamically adjust the antenna's resonance as its environment changes (e.g., when a hand grips the phone). While adding cost, this is a powerful solution to the hand-effect problem.

Multi-Band Support for Mass Markets: As high-accuracy GNSS (using L1 + L5 bands) trickles down from premium to mass-market applications, there is a growing need for low-cost antennas that can operate efficiently across these widely separated bands. This will drive innovation in multi-resonant, coupled-element designs.

Enhanced Integration:

Antenna-in-Package (AiP): The ultimate step in miniaturization is to embed the antenna directly into the package of the GNSS receiver chip itself. This would save PCB space and simplify design but presents immense challenges in isolating the antenna from the noise of the silicon die and achieving good efficiency.

Use of Device Elements: Using parts of the device itself, such as the metal frame or display bezel, as radiating elements to improve performance.

Advancements in Simulation: More powerful and accessible electromagnetic (EM) simulation software will allow designers to accurately model the entire system—antenna, PCB, components, and housing—virtually before building prototypes. This will reduce design cycles, cost, and risk.

Material Science: Development of lower-cost ceramic and polymer-ceramic composite materials with lower loss tangents and stable dielectric constants will enable better efficiency or smaller sizes without increasing cost.

The low-cost passive ceramic antenna will remain the dominant solution for consumer GNSS for the foreseeable future. Its evolution will be characterized by incremental improvements in bandwidth, stability, and integration depth, continuing to enable new and innovative location-aware applications.

Conclusion

The low-cost passive GNSS ceramic antenna is a testament to the principle that the most impactful technologies are often the most invisible. It is a component that embodies the central ethos of modern consumer electronics: the relentless pursuit of miniaturization and cost reduction to enable functionality at a scale that transforms society. It has been the critical hardware enabler in the journey of GNSS from a specialized tool to a universal utility, as essential as the processor or the battery in powering the location-based economy.

Its story, however, is one of nuanced trade-offs. Its low purchase price is counterbalanced by a high design-cost threshold. It offers the gift of integration but demands the expertise of careful system-level RF design in return. It is a component that punishes negligence with failed performance but rewards diligent implementation with reliable, cost-effective functionality. It teaches a crucial lesson: in RF design, there are no truly independent components; everything is part of a interconnected system.

The challenges it presents—sensitivity to environment, body detuning, and low efficiency—are not mere drawbacks but the direct physical consequences of its microscopic size and minuscule cost. They are the boundaries within which engineers must innovate, driving advancements in materials, simulation, and design techniques.

As we look to a future of ever-more connected IoT devices, autonomous systems, and pervasive computing, the demand for small, cheap, and ubiquitous positioning will only intensify. The low-cost passive ceramic antenna, continually evolving to become more robust, more wideband, and more intelligent, will remain the fundamental hardware gateway between the physical world and the digital constellations overhead. It is a humble ceramic chip, but it is the foundation upon which our located, connected world is built.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)