Overview

The design and construction of an integrated custom GNSS patch antenna is a meticulous, iterative process that blends electromagnetic theory, materials science, and mechanical engineering. It begins not with the antenna itself, but with a comprehensive set of system requirements and constraints derived from the host device.

1. Initial Requirements Gathering:

The process starts by defining key parameters:

Target GNSS Frequency Bands: The antenna must cover the relevant bands: L1 (1575.42 MHz), L2 (1227.60 MHz), L5 (1176.45 MHz), and/or others like Galileo E1/E5a/E5b. Multi-band operation is increasingly common.

Physical Form Factor: The available volume, height (z-height), and footprint are often the most limiting factors, especially in slim devices like phones or trackers.

Performance Metrics: Required gain, efficiency, axial ratio (for circular polarization purity), and hemispherical coverage (a key factor for maintaining a lock on satellites at low elevations).

Environmental Conditions: Operating temperature range, resistance to humidity, UV exposure, vibration, and shock.

Integration Method: Will it be a standalone module, a printed-on-PCB (PCB-embedded) antenna, or a laser-direct-structured (LDS) antenna molded into the plastic housing?

2. Substrate Selection:

The choice of dielectric substrate material is critical as it directly influences the antenna's size, bandwidth, and efficiency. The physical size of a patch antenna is inversely proportional to the square root of the substrate's dielectric constant (εr). A high εr allows for a smaller antenna but typically at the cost of reduced bandwidth and efficiency. For GNSS, where bandwidth is needed for multi-band operation and high efficiency is non-negotiable, designers often use substrates with moderate εr (e.g., 3.0 to 10). Common materials include:

FR-4: Standard PCB material. Low cost but lossy (high dissipation factor) at GHz frequencies, leading to poor efficiency. Suitable only for less demanding applications.

Rogers RO4000系列 or Taconic TLY系列: Specialty high-frequency laminates. They have stable dielectric constants, low loss tangents, and are the preferred choice for high-performance custom GNSS antennas, despite their higher cost.

Ceramic-filled composites: Very high εr (e.g., 20-40), enabling extremely miniaturized antennas. However, they are brittle and have very narrow bandwidth, often requiring complex feeding techniques to make them usable for GNSS.

3. Patch Element and Feed Design:

The classic rectangular patch is just the starting point. Customization involves sophisticated geometries to meet the requirements:

Feeding Mechanism: How power is delivered to the antenna is crucial. Probe feeding (via a coaxial connector) is simple but not ideal for thin profiles. Microstrip line feeding is planar but can introduce spurious radiation. Aperture-coupled feeding, where the patch is excited through a slot in the ground plane, isolates the feed network from the radiator, offering excellent bandwidth and performance but with increased complexity.

Multiband Techniques: To cover multiple GNSS bands, single patches are insufficient. Designers use:

Stacked Patches: A smaller patch for a higher band (e.g., L1) is placed on top of a larger patch for a lower band (e.g., L2/L5). This is a common high-performance approach.

Slotted Patches: Introducing U-shaped or other slots on the patch surface can perturb current paths and create multiple resonant modes.

Multi-Arm Fractals: Geometries like the Hilbert curve can create multiple resonances from a single, compact structure.

4. The Ground Plane and Integration:

The antenna's performance is profoundly affected by the size and shape of the ground plane upon which it is built. In an integrated design, the device's own PCB often serves as the ground plane. A critical rule of thumb is that the ground plane should extend at least a quarter-wavelength (~4 cm at L1 band) beyond the edge of the radiator for optimal performance. If the device's PCB is smaller than this, the radiation pattern will be distorted, and gain will drop significantly. This is a primary reason for customization—the antenna design must be simulated and tuned with the exact dimensions of the host device's PCB to predict and correct for these effects.

5. The Role of Simulation and Prototyping:

Modern antenna design is impossible without 3D electromagnetic field simulators like ANSYS HFSS, CST Studio Suite, or Keysight ADS. Engineers create a virtual model of the antenna, including its precise integration into the device model, complete with nearby components (batteries, screens, cameras), the plastic housing, and even the user's hand. They simulate performance across frequency, optimize geometry, and iterate rapidly before a physical prototype is ever built. Only after simulation predicts acceptable performance are prototypes manufactured and tested in an anechoic chamber to validate the models.

6. Construction and Assembly:

The final construction method depends on the chosen integration path:

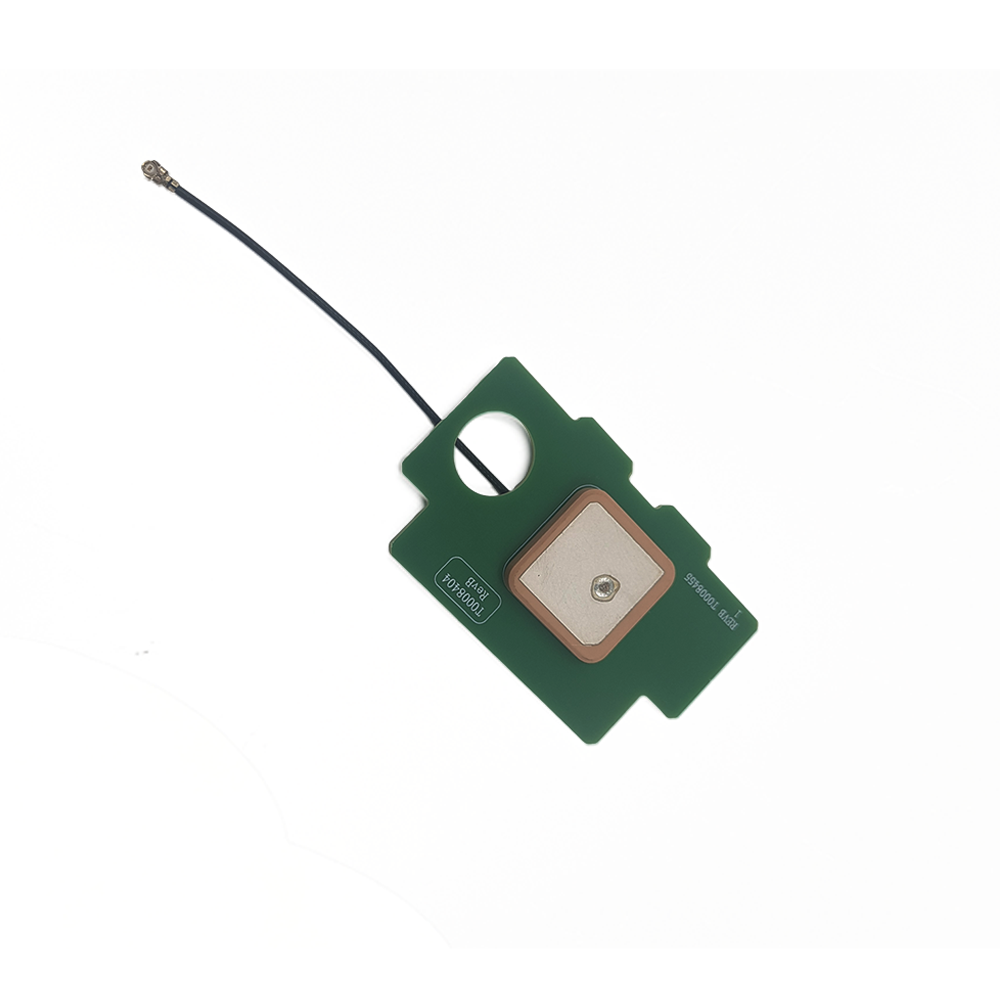

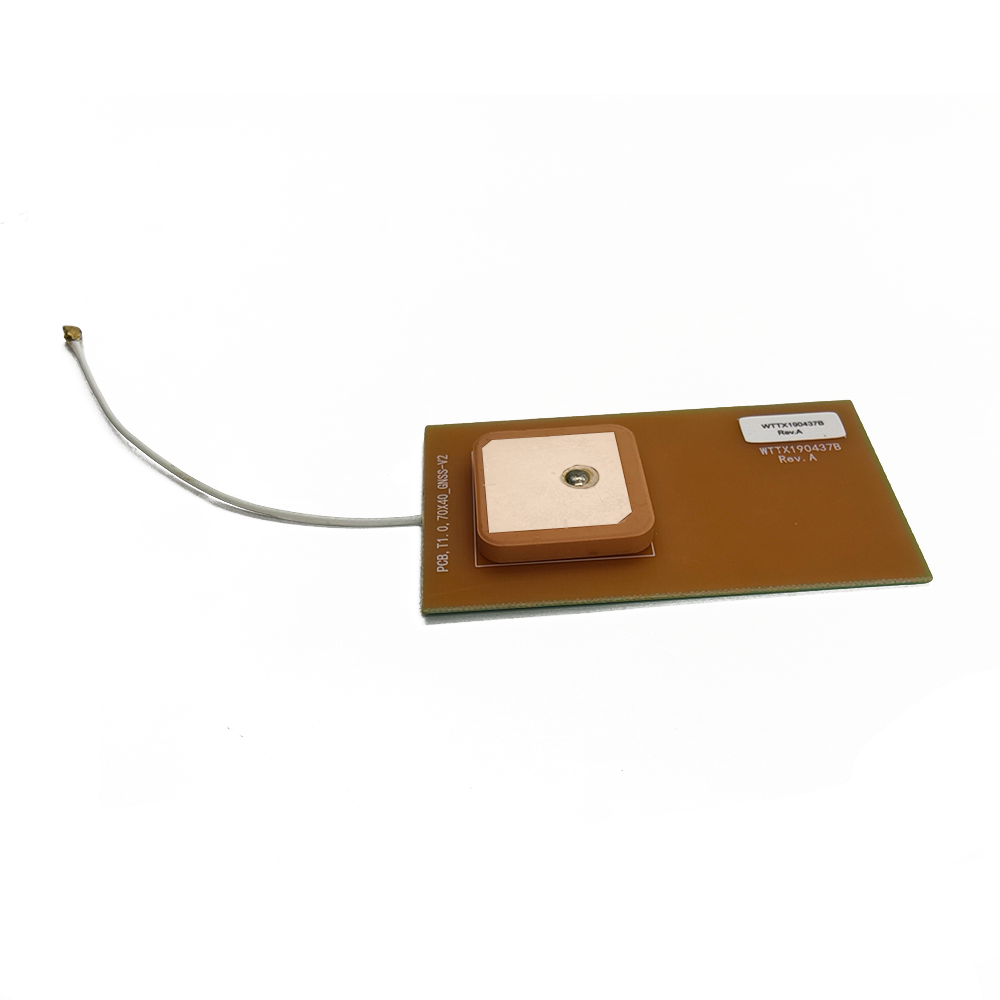

PCB-Embedded: The antenna is photolithographically etched directly onto the main device PCB or a separate sub-PCB. This is low-cost and highly integrated but requires careful management of lossy substrate materials.

Ceramic Patch: A standalone ceramic antenna element is purchased and soldered onto the PCB. This offers good performance in a small package.

LDS (Laser Direct Structuring): A plastic housing component is injection-molded with a special doped thermoplastic. A laser then etches the antenna pattern directly onto the plastic, which is subsequently metallized via electroless plating. This allows for complex 3D antenna shapes that conform to the available space inside the device, offering immense design freedom.

In conclusion, the design and construction of an integrated custom GNSS patch antenna is a complex, multi-disciplinary effort. It transforms a simple theoretical concept into a practical, high-performance component whose identity is fused with the product it enables.

Design and Construction

The operation of an integrated custom GNSS patch antenna is rooted in the fundamental principles of radiating electromagnetic waves, but its customized nature means its behavior is finely tuned for the specific task of receiving RHCP signals from medium Earth orbit (MEO) satellites.

1. Basic Resonance:

At its core, a patch antenna is a resonant cavity. The metal patch and the larger ground plane form two parallel conducting surfaces, and the substrate between them acts as the cavity's dielectric filler. The most fundamental mode of operation is the TM₁₀ mode. The resonant length (L) of the patch is approximately half the wavelength in the dielectric medium, which determines the central operating frequency. The formula is given by:

L ≈ c / (2f * √(ε_eff))

where c is the speed of light, f is the resonant frequency, and ε_eff is the effective dielectric constant of the substrate. This equation highlights why high-εr substrates shrink the antenna size. The patch radiates from its edges, where the fringing electric fields between the patch and the ground plane "leak" out into space. The radiation pattern is broad, typically directed perpendicular to the plane of the patch (broadside).

2. Achieving Circular Polarization:

GNSS satellites transmit RHCP signals to mitigate signal degradation caused by atmospheric effects like Faraday rotation and to ensure the signal can be received regardless of the satellite's orientation relative to the receiver. A standard patch radiator produces linear polarization. To convert this to circular polarization, the antenna must radiate two orthogonal electric field components of equal amplitude but with a 90-degree phase difference.

Custom patch antennas achieve this through deliberate design perturbations. The two most common methods are:

Single-Feed with Perturbation: A small physical distortion is introduced into the otherwise square patch—often a truncated corner, a diagonal slot, or a notch. This perturbation splits the natural resonant frequency of the patch into two orthogonal modes (e.g., along the x and y axes). By carefully sizing the perturbation, these two modes are tuned to have equal amplitudes and a 90-degree phase shift at the desired GNSS frequency, resulting in circular polarization. This is a simple and compact method.

Dual-Feed with Hybrid Coupler: Two separate feed points are located on the patch, positioned to excite two orthogonal modes. The feeds are supplied with signals of equal amplitude but with a precise 90-degree phase shift, which is typically provided by a external quadrature hybrid coupler circuit. This method offers superior axial ratio (purer circular polarization) and wider bandwidth but requires more space on the PCB for the feed network.

3. The Integrated Environment's Impact on Operation:

This is where the "integrated" and "custom" aspects profoundly affect the working principles. The antenna does not operate in free space; it operates in a complex environment that alters its behavior.

Ground Plane Effects: As mentioned, the finite size of the device's PCB ground plane causes currents to reflect from its edges. This interferes with the primary radiation, altering the radiation pattern. It can create nulls or "holes" in the coverage at certain angles, which could cause the receiver to lose lock on a satellite if it flies through that null. Custom design involves simulating the exact ground plane and often adding features like via fences or bezels to control edge diffraction.

Near-Field Coupling: Nearby components are not passive observers. A large battery is a lossy dielectric object that can detune the antenna's resonant frequency and absorb radiated energy, drastically reducing efficiency. A metal display shield can reflect signals, creating multipath interference where the receiver gets a direct signal and a reflected signal, corrupting the timing calculation. The custom design process involves strategically placing the antenna—often in a "clear zone" free of obstructions—and using EM simulation to model these interactions and reshape the antenna to compensate for them.

User Interaction (Hand Effect): In a smartphone or handheld device, the user's hand and head become part of the operational environment. The body is mostly water, which is highly lossy at GHz frequencies. It absorbs RF energy, blocks signals, and detunes the antenna. A robust custom design might incorporate tuning circuits or adaptive impedance matching networks that can sense the impedance shift caused by the hand and dynamically retune the antenna to maintain efficiency—a feature impossible with a standard antenna.

4. Phase Center and Precision Operation:

For standard positioning, the antenna's phase center—the virtual point from which the radiation seems to emanate—does not need to be perfectly stable. However, for high-precision applications using Real-Time Kinematic (RTK) or Precise Point Positioning (PPP) techniques, which rely on the phase of the carrier wave itself to achieve centimeter-level accuracy, a stable and well-known phase center is paramount. Any movement of the phase center with frequency or angle of arrival introduces errors. Custom high-precision GNSS antennas are meticulously designed to have a phase center that is as constant as possible across the entire operating band and across the upper hemisphere. This is achieved through symmetrical, balanced designs (like choked ring or dual-feed patches) and careful calibration.

In essence, the working principle of an integrated custom GNSS antenna extends beyond simple radiation. It is the principle of operating optimally within a hostile and complex electromagnetic environment, ensuring that the incredibly weak satellite signal is captured with maximum efficiency, minimal distortion, and the correct polarization to provide a reliable and accurate data stream to the receiver.

Working Principles

The operation of an integrated custom GNSS patch antenna is rooted in the fundamental principles of radiating electromagnetic waves, but its customized nature means its behavior is finely tuned for the specific task of receiving RHCP signals from medium Earth orbit (MEO) satellites.

1. Basic Resonance:

At its core, a patch antenna is a resonant cavity. The metal patch and the larger ground plane form two parallel conducting surfaces, and the substrate between them acts as the cavity's dielectric filler. The most fundamental mode of operation is the TM₁₀ mode. The resonant length (L) of the patch is approximately half the wavelength in the dielectric medium, which determines the central operating frequency. The formula is given by:

L ≈ c / (2f * √(ε_eff))

where c is the speed of light, f is the resonant frequency, and ε_eff is the effective dielectric constant of the substrate. This equation highlights why high-εr substrates shrink the antenna size. The patch radiates from its edges, where the fringing electric fields between the patch and the ground plane "leak" out into space. The radiation pattern is broad, typically directed perpendicular to the plane of the patch (broadside).

2. Achieving Circular Polarization:

GNSS satellites transmit RHCP signals to mitigate signal degradation caused by atmospheric effects like Faraday rotation and to ensure the signal can be received regardless of the satellite's orientation relative to the receiver. A standard patch radiator produces linear polarization. To convert this to circular polarization, the antenna must radiate two orthogonal electric field components of equal amplitude but with a 90-degree phase difference.

Custom patch antennas achieve this through deliberate design perturbations. The two most common methods are:

Single-Feed with Perturbation: A small physical distortion is introduced into the otherwise square patch—often a truncated corner, a diagonal slot, or a notch. This perturbation splits the natural resonant frequency of the patch into two orthogonal modes (e.g., along the x and y axes). By carefully sizing the perturbation, these two modes are tuned to have equal amplitudes and a 90-degree phase shift at the desired GNSS frequency, resulting in circular polarization. This is a simple and compact method.

Dual-Feed with Hybrid Coupler: Two separate feed points are located on the patch, positioned to excite two orthogonal modes. The feeds are supplied with signals of equal amplitude but with a precise 90-degree phase shift, which is typically provided by a external quadrature hybrid coupler circuit. This method offers superior axial ratio (purer circular polarization) and wider bandwidth but requires more space on the PCB for the feed network.

3. The Integrated Environment's Impact on Operation:

This is where the "integrated" and "custom" aspects profoundly affect the working principles. The antenna does not operate in free space; it operates in a complex environment that alters its behavior.

Ground Plane Effects: As mentioned, the finite size of the device's PCB ground plane causes currents to reflect from its edges. This interferes with the primary radiation, altering the radiation pattern. It can create nulls or "holes" in the coverage at certain angles, which could cause the receiver to lose lock on a satellite if it flies through that null. Custom design involves simulating the exact ground plane and often adding features like via fences or bezels to control edge diffraction.

Near-Field Coupling: Nearby components are not passive observers. A large battery is a lossy dielectric object that can detune the antenna's resonant frequency and absorb radiated energy, drastically reducing efficiency. A metal display shield can reflect signals, creating multipath interference where the receiver gets a direct signal and a reflected signal, corrupting the timing calculation. The custom design process involves strategically placing the antenna—often in a "clear zone" free of obstructions—and using EM simulation to model these interactions and reshape the antenna to compensate for them.

User Interaction (Hand Effect): In a smartphone or handheld device, the user's hand and head become part of the operational environment. The body is mostly water, which is highly lossy at GHz frequencies. It absorbs RF energy, blocks signals, and detunes the antenna. A robust custom design might incorporate tuning circuits or adaptive impedance matching networks that can sense the impedance shift caused by the hand and dynamically retune the antenna to maintain efficiency—a feature impossible with a standard antenna.

4. Phase Center and Precision Operation:

For standard positioning, the antenna's phase center—the virtual point from which the radiation seems to emanate—does not need to be perfectly stable. However, for high-precision applications using Real-Time Kinematic (RTK) or Precise Point Positioning (PPP) techniques, which rely on the phase of the carrier wave itself to achieve centimeter-level accuracy, a stable and well-known phase center is paramount. Any movement of the phase center with frequency or angle of arrival introduces errors. Custom high-precision GNSS antennas are meticulously designed to have a phase center that is as constant as possible across the entire operating band and across the upper hemisphere. This is achieved through symmetrical, balanced designs (like choked ring or dual-feed patches) and careful calibration.

In essence, the working principle of an integrated custom GNSS antenna extends beyond simple radiation. It is the principle of operating optimally within a hostile and complex electromagnetic environment, ensuring that the incredibly weak satellite signal is captured with maximum efficiency, minimal distortion, and the correct polarization to provide a reliable and accurate data stream to the receiver.

Advantages and Challenges

-

The adoption of an integrated custom GNSS patch antenna offers a compelling set of advantages over off-the-shelf solutions, but these benefits come with significant engineering challenges and costs that must be carefully weighed during product development.

Advantages:

Optimal Performance in Final Form: This is the paramount advantage. A custom antenna is designed, simulated, and tested within the context of the final product. This proactive approach neutralizes the negative effects of the device's own electronics, housing, and user interaction. The result is maximized efficiency, a stable radiation pattern, and reliable satellite acquisition and tracking that a generic antenna could never guarantee once placed inside a device.

Form Factor and Aesthetic Integration: Customization allows the antenna to conform to the available space, however irregular. Through techniques like LDS, the antenna can be molded into the device's bezel, housing, or any non-metallic surface, making it virtually invisible. This enables sleek, minimalist product designs without unsightly external antenna protrusions, which is critical for consumer electronics and automotive interiors.

Size Reduction and Miniaturization: By leveraging high-dielectric-constant materials and advanced geometries like fractals, custom antennas can be made extremely small while still functioning effectively. This is essential for the ongoing trend of miniaturization in IoT devices, wearables, and compact trackers.

Multi-Band and Multi-Function Capability: A single custom-designed antenna element can be engineered to cover multiple GNSS bands (L1, L2, L5), and can even be co-designed to support other wireless services like Bluetooth, Wi-Fi, or cellular (4G/5G) in a single integrated component. This reduces the number of separate antennas needed in a device, saving space, cost, and reducing RF interference.

Enhanced Robustness and Reliability: When an antenna is integrated via LDS or embedded into a housing, it is mechanically robust. It is less susceptible to damage from shock, vibration, or accidental mishandling compared to a solder-mounted standalone component that could break off its pads. Furthermore, its performance is consistent and guaranteed from unit to unit in mass production.

Challenges:

High Non-Recurring Engineering (NRE) Costs: The custom design process is expensive. It requires significant engineering time, access to expensive EM simulation software licenses, and the fabrication of multiple prototype iterations for testing in specialized anechoic chambers. These upfront costs can be prohibitive for low-volume products.

Design Complexity and Expertise: Successfully designing a custom integrated antenna requires rare and specialized expertise in RF and electromagnetics. It is a non-trivial task that involves navigating complex trade-offs between size, bandwidth, efficiency, and cost. A design error can lead to a non-functional product, costly respins of PCBs or molds, and significant project delays.

Longer Development Timeline: The cycle of design, simulation, prototyping, and testing is iterative and time-consuming. It can add weeks or months to a product's development schedule compared to simply selecting a pre-certified antenna from a catalog and soldering it onto a board.

Manufacturing and Yield Considerations: While the end assembly might be robust, the manufacturing process itself can introduce variability. For PCB-embedded antennas, inconsistencies in the laminate's dielectric constant or etching precision can slightly shift the resonant frequency. For LDS, the plating thickness and consistency can affect performance. Tight tolerances and rigorous quality control are needed to ensure high production yield and consistent performance across thousands of units.

Testing and Certification Complexity: Testing an integrated antenna is more difficult than testing a connectorized standalone unit. It requires radiated performance tests (TRP/TIS) of the entire device, which is more complex than conducted tests. Furthermore, any significant change to the device's PCB layout or housing late in the design process can detune the antenna, necessitating a partial re-design and re-testing.

In conclusion, the decision to pursue a custom integrated antenna is a strategic one. The advantages in performance, size, and integration are undeniable for high-volume or performance-critical applications. However, the associated costs, time, and complexity make it a solution that is best justified when the product's core functionality and market success depend on superior and reliable GNSS performance.

Applications and Future Trends

-

Integrated custom GNSS patch antennas have moved from being niche components to enablers of transformative technologies across diverse industries. Their ability to deliver reliable, high-fidelity positioning in constrained and challenging environments unlocks new capabilities and drives innovation.

Applications:

Consumer Electronics:

Smartphones and Tablets: This is the highest-volume application. Custom antennas are essential to achieve acceptable GPS performance while crammed between the battery, display, cameras, and metal chassis. They are often LDS antennas molded into the phone's plastic mid-frame or bezel.

Wearables: Smartwatches, fitness trackers, and personal locator beacons have extreme size constraints. Tiny ceramic or PCB-embedded custom patches are used to provide location tracking for fitness metrics and safety applications.

Automotive and Telematics:

Telematics Control Units (TCUs) and eCall: antennas are integrated into the roof liner, dashboard, or rear window to provide vehicle location for emergency services, stolen vehicle recovery, and usage-based insurance.

Advanced Driver-Assistance Systems (ADAS) and Autonomous Vehicles: High-precision positioning is a cornerstone of autonomy. Custom multi-band antennas with stable phase centers are integrated into the vehicle's roof or spoiler to receive correction data (for RTK) and provide centimeter-accurate localization, often fused with LiDAR, radar, and camera data.

Unmanned Aerial Vehicles (UAVs/Drones):

Drones for surveying, mapping, agriculture, and delivery rely on highly accurate GNSS for autonomous flight and precision landing. Custom, lightweight, and low-profile antennas are integrated into the drone's airframe to minimize drag and provide a clear view of the sky, often combining GNSS with other radio links.

Precision Agriculture and Surveying:

Agricultural machinery uses auto-steering systems guided by RTK-GNSS to plant, fertilize, and harvest with centimeter precision, reducing overlap and waste. Similarly, survey equipment requires the highest accuracy. These systems use large, ruggedized, custom-designed choke ring or dual-frequency patch antennas to mitigate multipath from the ground and ensure phase center stability.

Industrial IoT and Asset Tracking:

Tracking containers, machinery, and valuable assets across global supply chains requires robust, low-power GNSS modules. Custom antennas are integrated into ruggedized tags and trackers to survive harsh environments while providing reliable location data over cellular or satellite IoT networks.

Future Trends:

Tighter Integration and "Antenna as a Surface": The trend will continue towards deeper integration, where the antenna is not just in the device but is the device. Conductive inks, paint-on antennas, and advanced LDS processes will allow any non-metallic surface to become a functional radiator.

AI-Driven Antenna Design: Machine learning and artificial intelligence are beginning to be used to optimize antenna geometries. AI algorithms can explore millions of potential shape variations much faster than human engineers, arriving at highly efficient, non-intuitive designs optimized for specific constraints and performance goals.

Advanced Materials:

Metamaterials: Engineered materials with properties not found in nature could lead to super-compact antennas or ones with extraordinary beam-steering capabilities.

Low-Loss, Stable Polymers: New substrate materials with ultra-low loss tangents and dielectric constants stable across temperature and frequency will enable smaller, more efficient, and more reliable antennas.

Beamforming and Adaptive Antennas: To combat jamming and interference—a critical concern for safety-of-life applications—future custom antennas will incorporate multi-element arrays. Using techniques like controlled reception pattern antenna (CRPA) technology, these arrays can electronically form nulls in the direction of jammers while maximizing gain towards satellites. This will be key for autonomous vehicles and drones.

Multi-Function "System-on-Substrate" Antennas: The future will see a single integrated custom component that functions as a unified antenna for all of a device's wireless needs: GNSS, 5G (including mmWave), Wi-Fi 6E/7, UWB, and Bluetooth. This will require incredibly complex design but will be necessary for the ever-increasing connectivity demands of modern devices.

The future of integrated custom GNSS antennas is one of increasing intelligence, miniaturization, and multifunctionality, seamlessly blending into products to provide the ubiquitous and resilient positioning required by the next generation of connected and autonomous technology.

Conclusion

The journey from a basic patch antenna concept to a fully integrated custom GNSS solution epitomizes the evolution of modern electronic design. It is a transition from treating the antenna as a discrete, standalone component to recognizing it as an intrinsic, co-engineered element of a complete system. This paradigm shift is not merely optional but is increasingly mandatory for products where performance, size, reliability, and user experience are paramount competitive differentiators.

The overview established the critical role of these antennas in capturing faint satellite signals. The deep dive into design and construction revealed the intricate balance of materials science, electromagnetic theory, and mechanical engineering required to tailor the antenna to its environment. The discussion on working principles explained how customization manipulates fundamental physics to achieve circular polarization and overcome the deleterious effects of integration. The analysis of advantages and challenges provided a sobering reality check: the unparalleled performance and seamless integration come at a significant cost in expertise, time, and money, confining this approach to applications where the return on investment is clear.

Finally, the exploration of applications and future trends underscores that this technology is not static. It is a dynamic field driving and being driven by the most cutting-edge innovations in consumer electronics, autonomous systems, and the Internet of Things. The trends point towards even deeper integration, intelligent and adaptive systems, and the convergence of multiple radio services into a single, sophisticated aperture.

In conclusion, the integrated custom GNSS patch antenna is far more than a simple metal patch on a circuit board. It is the result of a sophisticated design process that acknowledges a simple truth: an antenna's performance is meaningless in isolation. Its true value is only realized when it is perfectly harmonized with the device it empowers. As our world becomes more connected and location-aware, the silent, hidden work of these custom-designed components will continue to be a foundational enabler of the technological advancements that define our future.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)