5.1 Current Applications

5.1.1 Precision Agriculture

Precision agriculture is one of the key application areas for integrated GNSS RTK ceramic patch antennas. In precision agriculture, the goal is to optimize crop yields while minimizing the use of resources such as water, fertilizers, and pesticides. This requires accurate positioning of agricultural machinery, such as tractors, harvesters, and sprayers, to ensure that resources are applied only where they are needed.

Integrated GNSS RTK ceramic patch antennas are ideal for this application due to their compact size, lightweight design, and high precision. These antennas can be integrated into the navigation systems of agricultural machinery, providing centimeter - level positioning accuracy. For example, a tractor equipped with an integrated GNSS RTK ceramic patch antenna can follow a pre - defined path with an accuracy of less than 5 cm, ensuring that seeds are planted in straight rows and that fertilizers are applied evenly across the field.

In addition, these antennas can be used in unmanned aerial vehicles (UAVs) for agricultural monitoring and spraying. UAVs equipped with integrated GNSS RTK ceramic patch antennas can fly over fields with high precision, capturing images of crops to monitor their health and applying pesticides or fertilizers to specific areas. The lightweight design of the antenna ensures that the UAV can carry additional payloads, such as cameras or sprayers, and fly for longer periods.

5.1.2 Autonomous Driving

Autonomous driving is another important application area for integrated GNSS RTK ceramic patch antennas. Autonomous vehicles require accurate and reliable positioning to navigate safely on roads, avoid obstacles, and follow traffic rules. GNSS RTK technology, combined with other sensors such as lidar, radar, and cameras, provides the high - precision positioning required for autonomous driving.

Integrated GNSS RTK ceramic patch antennas are well - suited for this application due to their high integration level, excellent interference rejection, and compact size. These antennas can be integrated into the vehicle's navigation system, providing centimeter - level positioning accuracy even in challenging environments such as urban canyons. The multi - band capability of the antenna allows it to track signals from multiple GNSS constellations, ensuring that the vehicle has access to a sufficient number of satellites even when some signals are blocked by buildings or other obstacles.

The excellent interference rejection of the antenna is also critical in autonomous driving applications. Urban environments are filled with sources of electromagnetic interference, such as cellular towers, Wi - Fi hotspots, and other electronic devices. The integrated LNA and BPF in the antenna help to reject these interfering signals, ensuring that the vehicle's navigation system receives only the desired GNSS signals. This reduces the risk of positioning errors, which can lead to accidents.

5.1.3 Surveying and Mapping

Surveying and mapping is a traditional application area for GNSS RTK technology, and integrated GNSS RTK ceramic patch antennas are increasingly being used in this field. Surveyors and mappers require accurate positioning of points on the ground to create maps, measure land boundaries, and plan construction projects.

Integrated GNSS RTK ceramic patch antennas offer several advantages for surveying and mapping applications. Their compact size and lightweight design make them easy to carry and set up, even in remote areas. The high precision of the antenna ensures that surveyors can measure points with an accuracy of less than 1 cm, which is essential for creating detailed maps and plans.

In addition, these antennas can be integrated into portable surveying equipment, such as handheld GNSS receivers. Handheld receivers equipped with integrated GNSS RTK ceramic patch antennas allow surveyors to collect data quickly and efficiently, without the need for bulky and expensive equipment. This makes surveying and mapping more accessible to small businesses and individual professionals.

5.1.4 Consumer Electronics

The consumer electronics market is a growing application area for integrated GNSS RTK ceramic patch antennas. With the increasing demand for location - based services (LBS) in smartphones, wearables, and other consumer devices, there is a need for high - precision GNSS antennas that can fit into compact devices.

Integrated GNSS RTK ceramic patch antennas are ideal for this application due to their compact size, lightweight design, and cost - effectiveness. These antennas can be integrated into smartphones, providing centimeter - level positioning accuracy for applications such as augmented reality (AR), indoor navigation, and location - based gaming. For example, in AR applications, the high - precision positioning provided by the antenna allows users to overlay digital information onto the real world with greater accuracy, enhancing the user experience.

Wearable devices, such as smartwatches and fitness trackers, also benefit from integrated GNSS RTK ceramic patch antennas. These devices require small and lightweight antennas that can provide accurate positioning for fitness tracking, outdoor navigation, and emergency services. The cost - effectiveness of the antenna makes it possible to integrate high - precision GNSS RTK capabilities into affordable wearable devices, expanding the market for these products.

5.2 Future Trends

5.2.1 Further Miniaturization

One of the key future trends in integrated GNSS RTK ceramic patch antennas is further miniaturization. As consumer devices become smaller and more compact, there is a growing demand for antennas that can fit into even smaller form factors. This requires the development of new materials and design techniques to reduce the size of the antenna without sacrificing performance.

One promising approach to further miniaturization is the use of advanced ceramic materials with higher dielectric constants. Materials such as barium strontium titanate (BST) have dielectric constants that can be tuned by applying an electric field, allowing for the design of antennas with even smaller dimensions. In addition, the use of 3D printing technology for manufacturing ceramic substrates and patch elements may enable the creation of complex, compact antenna designs that are not possible with traditional manufacturing techniques.

Another approach to miniaturization is the integration of multiple antennas into a single module. For example, a single integrated module could include a GNSS RTK ceramic patch antenna, a cellular antenna, and a Wi - Fi antenna, reducing the overall size and weight of the device. This requires the development of advanced integration techniques to minimize interference between the different antennas.

5.2.2 Improved Bandwidth and Multi - Band Capabilities

As the number of GNSS constellations and frequency bands continues to grow, there is a need for integrated GNSS RTK ceramic patch antennas with improved bandwidth and multi - band capabilities. This requires the development of new design techniques to increase the bandwidth of the antenna and support a wider range of frequency bands.

One approach to improving bandwidth is the use of metamaterials. Metamaterials are artificial materials with unique electromagnetic properties that can be designed to enhance the performance of antennas. For example, metamaterial substrates can be used to increase the bandwidth of ceramic patch antennas by reducing surface wave losses and improving the radiation pattern.

Another approach to improving multi - band capabilities is the use of reconfigurable antennas. Reconfigurable antennas can change their operating frequency, polarization, or radiation pattern in response to external stimuli, such as an electric or magnetic field. This allows a single antenna to support multiple GNSS bands, reducing the size and complexity of the device. For example, a reconfigurable ceramic patch antenna could be designed to switch between the GPS L1, L2, and L5 bands, as well as the Galileo E1 and E5b bands, depending on the available satellite signals.

5.2.3 Enhanced Robustness to Environmental Factors

Future integrated GNSS RTK ceramic patch antennas will need to be more robust to environmental factors such as temperature changes, mechanical deformation, and electromagnetic interference. This requires the development of new materials and design techniques to improve the antenna's durability and performance in harsh environments.

In terms of temperature robustness, the development of ceramic materials with near - zero temperature coefficients of dielectric constant and thermal expansion will help to minimize the impact of temperature changes on the antenna's performance. In addition, the use of advanced temperature - compensation techniques, such as the integration of microelectromechanical systems (MEMS) devices into the antenna module, may enable real - time adjustment of the antenna's parameters to compensate for temperature variations.

To improve mechanical robustness, the use of ceramic - composite materials with increased strength and flexibility will be essential. These materials can withstand mechanical stress and deformation without affecting the performance of the antenna. In addition, the development of new packaging techniques, such as the use of flexible enclosures, will help to protect the antenna from mechanical damage in dynamic environments.

In terms of electromagnetic interference, the integration of advanced filtering and signal processing techniques into the antenna module will be critical. For example, the use of adaptive filters that can dynamically adjust their frequency response to reject interfering signals will help to improve the antenna's performance in high - interference environments. In addition, the development of new shielding materials, such as graphene - based composites, may provide better electromagnetic shielding than traditional materials, reducing the impact of external interference.

5.2.4 Integration with Artificial Intelligence (AI) and Machine Learning (ML)

The integration of artificial intelligence (AI) and machine learning (ML) techniques into integrated GNSS RTK ceramic patch antennas is another emerging trend. AI and ML can be used to optimize the antenna's performance in real - time, improve the accuracy of positioning, and reduce the impact of interference and environmental factors.

One application of AI and ML in antenna design is the optimization of the antenna's parameters, such as the size and shape of the patch element, the dielectric constant of the substrate, and the design of the matching network. By using ML algorithms to analyze large amounts of data on antenna performance, engineers can design antennas with improved performance and efficiency.

In addition, AI and ML can be used in the signal processing stage to improve the accuracy of positioning. For example, ML algorithms can be used to predict and compensate for multipath interference, which is a major source of positioning errors in GNSS RTK systems. By analyzing historical data on multipath patterns in different environments, the algorithm can predict the occurrence of multipath interference and adjust the positioning calculations accordingly.

AI and ML can also be used to optimize the power consumption of the antenna module. By analyzing the usage patterns of the device and the available satellite signals, the algorithm can adjust the gain of the LNA and the operation of the filter to minimize power consumption while maintaining the required performance. This is particularly important for battery - powered devices such as wearables and UAVs.

Conclusion

Integrated GNSS RTK ceramic patch antennas have emerged as a critical component in modern high - precision positioning systems, offering a unique combination of compact size, lightweight design, high integration level, and cost - effectiveness. These antennas have revolutionized a wide range of applications, from precision agriculture and autonomous driving to surveying and mapping, and consumer electronics, by providing centimeter - level positioning accuracy in a compact and affordable package.

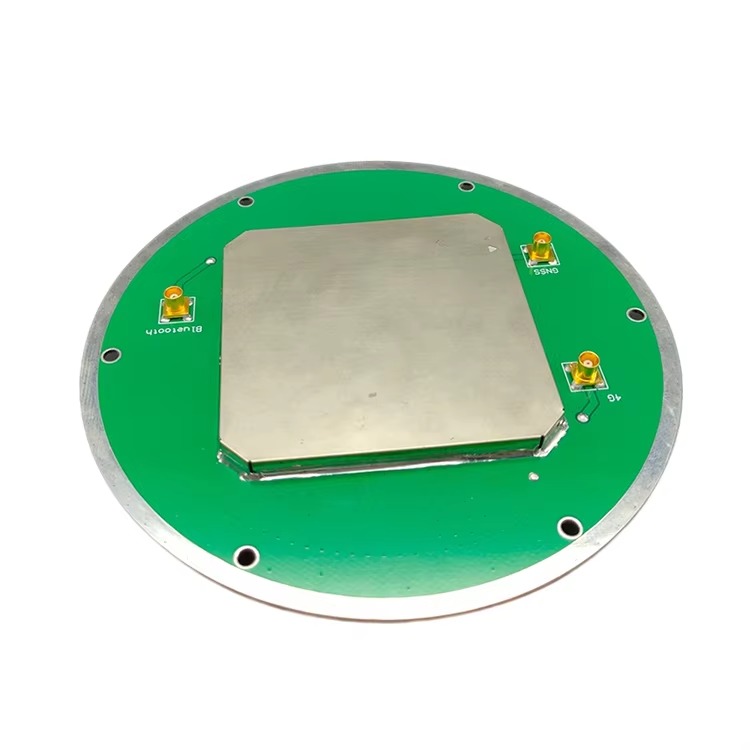

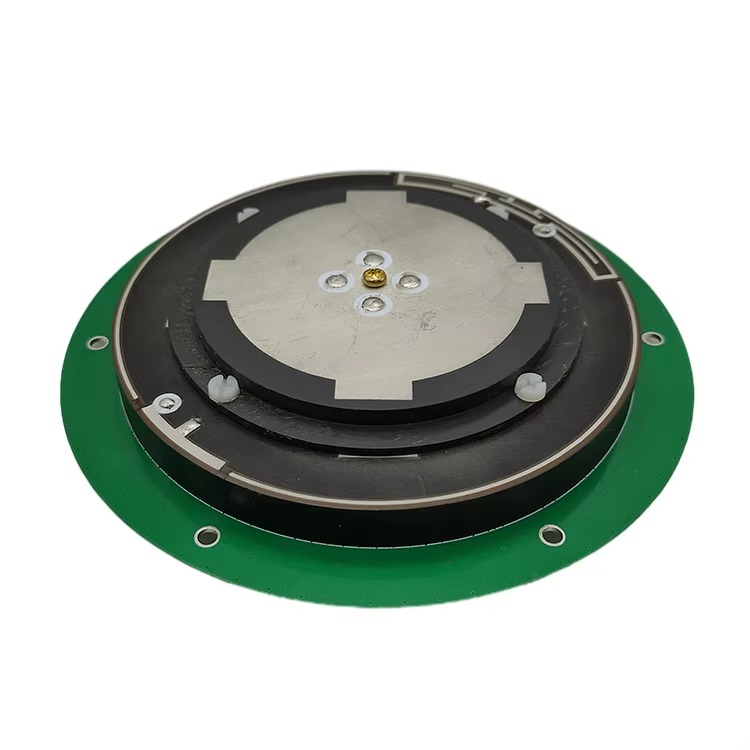

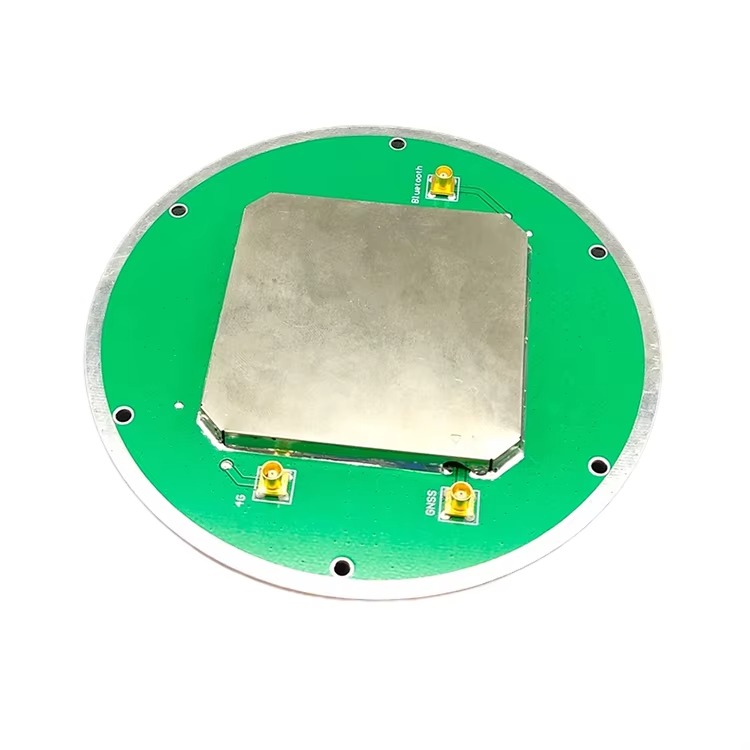

In this detailed exploration, we have examined the overview of integrated GNSS RTK ceramic patch antennas, including their role in GNSS RTK systems and the key characteristics that make them suitable for high - precision applications. We have also delved into the design and construction of these antennas, focusing on the selection of ceramic substrates, the design of patch elements, the integration of active and passive components, and the importance of enclosure and shielding.

The working principles of integrated GNSS RTK ceramic patch antennas have been thoroughly explained, covering signal reception and conversion, impedance matching, signal amplification and filtering, and the interaction with the RTK receiver. We have highlighted the critical role of each component, from the patch element that captures satellite signals to the LNA and BPF that ensure the signals are amplified and filtered for optimal processing by the receiver.

We have also analyzed the advantages and challenges of these antennas. The advantages, including compact size, high integration level, high performance in challenging environments, and cost - effectiveness, have made them a preferred choice for many applications. However, we have also acknowledged the challenges, such as limited bandwidth, sensitivity to mechanical deformation, temperature sensitivity, and cross - polarization interference, which need to be addressed to further improve the performance of these antennas.

Looking ahead, the future of integrated GNSS RTK ceramic patch antennas is promising, with several key trends emerging. Further miniaturization will enable these antennas to be integrated into even smaller devices, while improved bandwidth and multi - band capabilities will allow them to support the growing number of GNSS constellations and frequency bands. Enhanced robustness to environmental factors will make these antennas more suitable for harsh environments, and the integration of AI and ML techniques will optimize their performance and power consumption.

In conclusion, integrated GNSS RTK ceramic patch antennas have already made a significant impact on the field of high - precision positioning, and their importance is only set to grow in the coming years. As technology continues to advance, these antennas will play a crucial role in enabling new applications and improving the performance of existing ones, driving innovation in industries such as agriculture, automotive, surveying, and consumer electronics. With ongoing research and development, integrated GNSS RTK ceramic patch antennas will continue to evolve, overcoming current challenges and unlocking new possibilities for high - precision positioning.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)