GNSS RTK technology operates by establishing a communication link between a reference station with a known position and a rover station (the unit requiring positioning). The reference station continuously receives satellite signals, processes them, and transmits correction data to the rover station. The rover station then uses this correction data to refine its own position calculations, eliminating most of the errors associated with satellite signal propagation, such as ionospheric and tropospheric delays. For this intricate process to yield accurate results, the antenna at both the reference and rover stations must be capable of receiving satellite signals with exceptional clarity, stability, and minimal distortion.

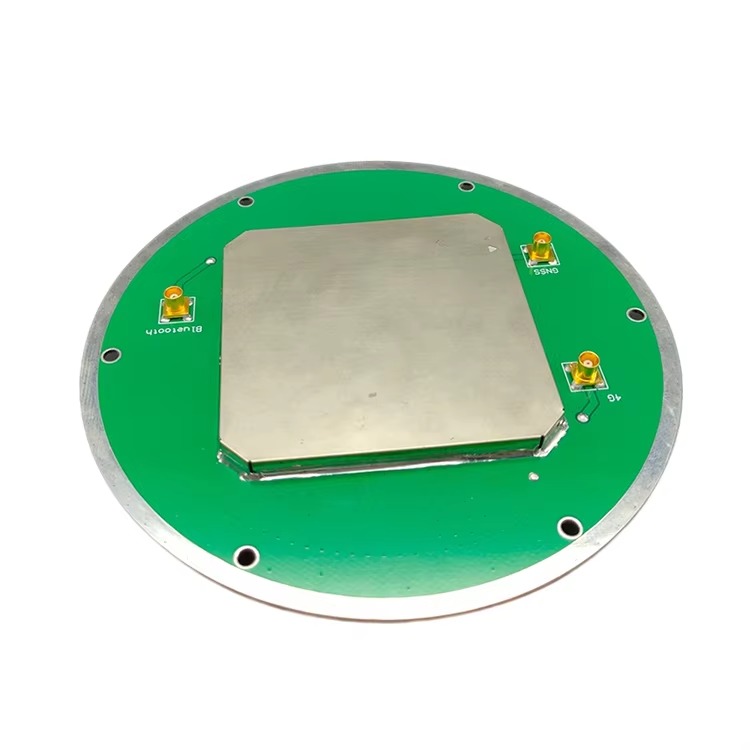

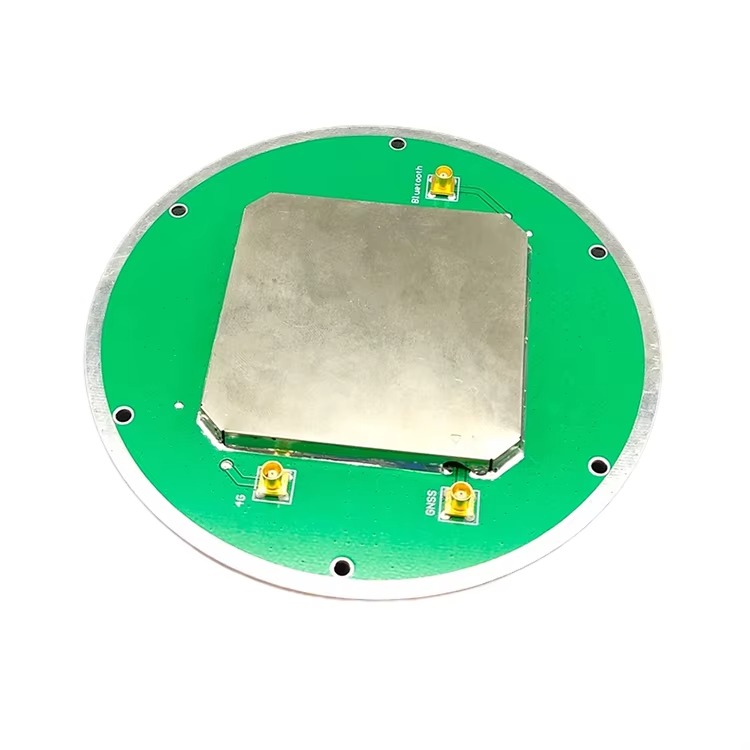

The ceramic patch antenna, also known as a microstrip patch antenna, is a planar antenna structure that has gained widespread adoption in GNSS RTK systems. Unlike traditional helical or dipole antennas, which often have bulkier designs, ceramic patch antennas are characterized by their low profile, lightweight construction, and excellent electrical performance. These attributes make them ideal for integration into a wide range of devices, from portable surveying equipment and unmanned aerial vehicles (UAVs) to autonomous vehicles and precision agricultural machinery.

One of the key advantages of ceramic patch antennas in GNSS RTK applications is their ability to maintain a stable phase center. The phase center is the point within the antenna from which the received satellite signals appear to originate. Any variation in the phase center can introduce significant errors into the position calculations, especially in high - precision RTK systems where even minute discrepancies can lead to meter - level inaccuracies. Ceramic patch antennas, when properly designed and manufactured, exhibit minimal phase center variation across different frequencies, elevation angles, and azimuth angles, ensuring consistent and reliable positioning results.

Another defining feature of high - precision GNSS RTK ceramic patch antennas is their wide frequency bandwidth. Modern GNSS systems, such as GPS (Global Positioning System), GLONASS (Globalnaya Navigatsionnaya Sputnikovaya Sistema), Galileo, and BeiDou, operate across multiple frequency bands. For example, GPS uses the L1 (1575.42 MHz), L2 (1227.60 MHz), and L5 (1176.45 MHz) bands, while BeiDou employs the B1 (1561.098 MHz), B2 (1207.14 MHz), and B3 (1268.52 MHz) bands. A high - quality ceramic patch antenna is designed to cover all these frequency bands simultaneously, enabling the receiver to track signals from multiple GNSS constellations. This multi - constellation and multi - frequency capability significantly improves the availability of satellite signals, even in challenging environments such as urban canyons or dense forests, where signal obstruction is common.

In addition to their electrical performance, ceramic patch antennas are also valued for their mechanical durability. The ceramic substrate, which forms the base of the antenna, is a robust material that can withstand harsh environmental conditions, including extreme temperatures, high humidity, and mechanical vibrations. This durability is particularly important for GNSS RTK applications that operate in outdoor settings, such as construction sites, agricultural fields, and remote surveying locations, where the antenna may be exposed to adverse weather and physical stress.

To fully appreciate the role of ceramic patch antennas in GNSS RTK systems, it is essential to understand the context of their use. In surveying and mapping, for instance, the ability to achieve centimeter - level accuracy is critical for creating detailed topographic maps, marking property boundaries, and ensuring the precise alignment of infrastructure projects. In precision agriculture, GNSS RTK - enabled equipment, equipped with ceramic patch antennas, allows farmers to apply fertilizers, pesticides, and irrigation with pinpoint accuracy, reducing waste and maximizing crop yields. In the field of autonomous vehicles, reliable high - precision positioning is a prerequisite for safe navigation, enabling the vehicle to detect obstacles, maintain lane position, and interact with other road users in real - time.

In summary, the high - precision GNSS RTK ceramic patch antenna is a vital component that enables the delivery of accurate, reliable, and real - time positioning data across a wide range of industries. Its unique combination of electrical performance, mechanical durability, and compact design makes it an indispensable technology in the modern world of location - based services. As GNSS technology continues to advance, and the demand for higher precision and greater reliability grows, the ceramic patch antenna is poised to play an even more significant role in shaping the future of positioning systems.

The design and construction of a high - precision GNSS RTK ceramic patch antenna are intricate processes that require careful consideration of numerous factors, including electrical performance, mechanical durability, and environmental compatibility. Each component of the antenna, from the ceramic substrate to the radiating patch and feed network, is designed to work in harmony to ensure optimal signal reception and conversion. In this section, we will delve into the key aspects of the design and construction of these antennas, exploring the materials used, the geometric considerations, and the manufacturing techniques employed.

2.1 Ceramic Substrate: The Foundation of Performance

The ceramic substrate is the backbone of the ceramic patch antenna, providing both mechanical support and electrical insulation for the radiating elements. The choice of ceramic material is critical, as it directly influences the antenna's electrical properties, such as its dielectric constant, loss tangent, and thermal stability.

2.1.1 Material Selection

The most commonly used ceramic materials for GNSS RTK antennas are alumina (Al₂O₃), zirconia (ZrO₂), and various ceramic - polymer composites. Alumina is a popular choice due to its high dielectric constant (typically in the range of 9 - 10), which allows for the miniaturization of the antenna. A higher dielectric constant means that the electromagnetic waves travel more slowly through the material, reducing the physical size of the antenna required to resonate at a given frequency. This miniaturization is particularly important for applications where space is limited, such as in portable devices or UAVs.

Zirconia, on the other hand, offers superior mechanical strength and thermal shock resistance compared to alumina. It has a dielectric constant of around 20 - 25, making it suitable for even smaller antenna designs. However, zirconia is more expensive than alumina, which limits its use to applications where mechanical durability is a top priority, such as in heavy - duty industrial equipment or automotive systems.

Ceramic - polymer composites, which combine ceramic particles with a polymer matrix (such as PTFE or epoxy), offer a balance between dielectric performance, mechanical flexibility, and cost. These composites can be tailored to have a specific dielectric constant by adjusting the ratio of ceramic to polymer, allowing for greater design flexibility. They also exhibit lower loss tangents than pure ceramics, which reduces signal attenuation and improves the antenna's efficiency.

2.1.2 Substrate Thickness and Dimensions

The thickness of the ceramic substrate is another critical design parameter. A thicker substrate generally results in a lower loss tangent and better radiation efficiency, but it also increases the overall size and weight of the antenna. For GNSS RTK applications, where compactness is often a requirement, the substrate thickness is typically kept between 0.5 mm and 3 mm. The dimensions of the substrate (length and width) are determined by the size of the radiating patch and the feed network, with sufficient margin to prevent edge effects from interfering with the antenna's performance.

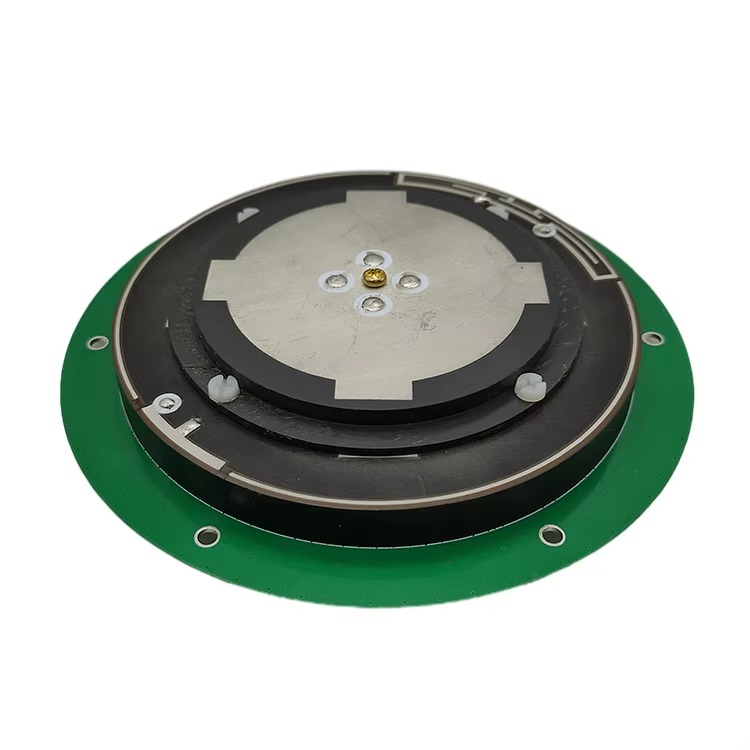

2.2 Radiating Patch: The Signal - Capturing Element

The radiating patch is the active component of the ceramic patch antenna, responsible for capturing satellite signals and converting them into electrical currents. The design of the patch, including its shape, size, and material, has a direct impact on the antenna's frequency response, gain, and polarization.

2.2.1 Patch Shape and Size

The most common shape for the radiating patch in GNSS RTK ceramic antennas is a rectangular or square geometry. This simple shape is easy to manufacture and provides a stable radiation pattern. The size of the patch is calculated based on the dielectric constant of the substrate and the desired operating frequency. The length (L) and width (W) of the patch can be approximated using the following formulas:

W = c / (2f₀√( (εᵣ + 1) / 2 ))

L = L₀ - 2ΔL

Where:

c is the speed of light in free space (3 × 10⁸ m/s)

f₀ is the center frequency of operation

εᵣ is the relative dielectric constant of the substrate

L₀ is the initial length (c / (2f₀√εᵣ))

ΔL is the extension of the patch length due to fringing fields (typically calculated using empirical formulas based on the substrate thickness and dielectric constant)

For multi - frequency GNSS applications, the patch may be designed with multiple resonant elements or a single broadband element. For example, a stacked patch design, where two or more patches are placed on top of each other with separate feed lines, can be used to cover multiple frequency bands. Alternatively, a single patch with a modified shape, such as a U - slot or a notched edge, can be designed to have a wider bandwidth, enabling it to operate across multiple GNSS bands.

2.2.2 Patch Material

The radiating patch is typically made of a highly conductive material, such as copper, silver, or gold. Copper is the most commonly used material due to its excellent electrical conductivity (5.96 × 10⁷ S/m) and relatively low cost. Silver and gold offer even higher conductivity (6.3 × 10⁷ S/m for silver and 4.52 × 10⁷ S/m for gold) but are more expensive, making them suitable for high - performance applications where maximum efficiency is required.

The patch is deposited onto the ceramic substrate using various manufacturing techniques, including screen printing, sputtering, and electroplating. Screen printing is a cost - effective method for large - scale production, where a thin layer of conductive ink (typically copper or silver) is printed onto the substrate through a stencil. Sputtering and electroplating, on the other hand, produce thinner and more uniform layers of metal, resulting in better electrical performance but higher manufacturing costs.

2.3 Feed Network: Delivering Signals to the Receiver

The feed network is responsible for transferring the electrical signals from the radiating patch to the GNSS receiver, while ensuring proper impedance matching and signal integrity. The design of the feed network is critical, as any mismatch or loss in the network can degrade the antenna's performance, leading to reduced gain and increased noise.

2.3.1 Feed Types

The most common feed configurations for ceramic patch antennas are the microstrip line feed and the coaxial probe feed.

Microstrip Line Feed: In this configuration, a narrow microstrip line is connected directly to one edge of the radiating patch. The microstrip line acts as a transmission line, carrying the signal from the patch to the receiver. The width of the microstrip line is designed to match the impedance of the patch (typically 50 ohms) to the impedance of the receiver, minimizing signal reflections. This feed type is simple to integrate into the antenna design and is well - suited for planar structures, making it ideal for compact GNSS RTK devices.

Coaxial Probe Feed: In a coaxial probe feed, a coaxial cable is used to feed the patch. The inner conductor of the cable is connected directly to the patch, while the outer conductor is connected to a ground plane beneath the ceramic substrate. This feed type offers better isolation between the feed line and the radiating elements, reducing electromagnetic interference (EMI). It is also more robust than the microstrip line feed, making it suitable for applications where mechanical stability is important. However, the coaxial probe feed can introduce additional losses due to the probe's inductance and capacitance, which must be carefully accounted for in the design.

2.3.2 Impedance Matching

Impedance matching is a critical aspect of the feed network design. The goal is to ensure that the impedance of the antenna (at the feed point) matches the impedance of the receiver (typically 50 ohms), maximizing the power transfer between the two. Any impedance mismatch will result in signal reflections, which can reduce the antenna's gain and introduce phase distortions.

To achieve impedance matching, various techniques can be employed, such as using a quarter - wavelength transformer, a stub matching network, or a tapered feed line. A quarter - wavelength transformer is a section of microstrip line with a specific impedance that is placed between the patch and the receiver. The length of the transformer is one - quarter of the wavelength at the center frequency, and its impedance is chosen to match the patch impedance to the receiver impedance. Stub matching networks, which consist of short or open - circuited microstrip stubs, can also be used to adjust the impedance of the feed line, compensating for any mismatch.

2.4 Ground Plane: Enhancing Radiation Performance

The ground plane is a conductive layer placed beneath the ceramic substrate, opposite the radiating patch. It serves several important functions, including reflecting electromagnetic waves back towards the patch, improving the antenna's radiation efficiency, and providing a reference for the electrical signals.

2.4.1 Ground Plane Design

The size of the ground plane is a critical design parameter. A larger ground plane generally results in a more directional radiation pattern and higher gain, but it also increases the overall size of the antenna. For GNSS RTK applications, where a wide beamwidth is often required to track satellites at low elevation angles, the ground plane is typically designed to be slightly larger than the radiating patch. A common rule of thumb is to make the ground plane at least λ/4 larger than the patch in all directions, where λ is the wavelength of the operating frequency.

The ground plane is usually made of the same conductive material as the radiating patch, such as copper or silver. It can be deposited onto the back of the ceramic substrate using the same manufacturing techniques as the patch, ensuring good adhesion and electrical conductivity. In some cases, the ground plane may be extended beyond the substrate to provide additional shielding against EMI, which is particularly important in high - precision applications where noise can degrade positioning accuracy.

2.5 Enclosure and Environmental Protection

High - precision GNSS RTK ceramic patch antennas are often used in harsh outdoor environments, where they are exposed to rain, snow, dust, extreme temperatures, and mechanical vibrations. To ensure long - term reliability and performance, the antenna must be protected by a robust enclosure.

2.5.1 Enclosure Materials

The enclosure is typically made of a durable material such as plastic (e.g., ABS, polycarbonate) or metal (e.g., aluminum, stainless steel). Plastic enclosures are lightweight, cost - effective, and offer good resistance to corrosion. They can also be molded into complex shapes, allowing for easy integration into various devices. Metal enclosures, on the other hand, provide better shielding against EMI and are more resistant to mechanical impact. However, they are heavier and more expensive than plastic enclosures, making them suitable for applications where ruggedness is a top priority.

2.5.2 Weatherproofing and Sealing

To protect the antenna from moisture and dust, the enclosure must be properly sealed. This is typically achieved using gaskets made of rubber or silicone, which are placed between the enclosure and the antenna's base. The gaskets create a tight seal that prevents water and dust from entering the enclosure, even in extreme weather conditions. In addition, the enclosure may be coated with a waterproof material, such as polyurethane, to further enhance its resistance to moisture.

The antenna's feed connector, which is used to connect the antenna to the receiver, is another critical point of entry for moisture and dust. To prevent this, the connector is often equipped with a waterproof seal, such as an O - ring, and may be rated to meet international standards for ingress protection (IP), such as IP67 or IP68. An IP67 rating means that the connector is dust - tight and can withstand immersion in water up to 1 meter for 30 minutes, while an IP68 rating allows for immersion in water at greater depths for longer periods.

2.6 Manufacturing Processes: Ensuring Precision and Consistency

The manufacturing of high - precision GNSS RTK ceramic patch antennas requires strict quality control and advanced manufacturing techniques to ensure that each antenna meets the required performance specifications. The key manufacturing steps include substrate fabrication, patch deposition, feed network integration, and assembly.

2.6.1 Substrate Fabrication

The ceramic substrate is typically manufactured using a powder metallurgy process. The ceramic powder (e.g., alumina, zirconia) is mixed with a binder material (e.g., polyvinyl alcohol) to form a paste, which is then pressed into the desired shape using a hydraulic press. The pressed substrate is then sintered in a high - temperature furnace (typically at temperatures between 1500°C and 1700°C) to densify the material and improve its mechanical and electrical properties. After sintering, the substrate is polished to achieve a smooth surface, which is essential for the proper deposition of the radiating patch.

2.6.2 Patch and Feed Network Deposition

The radiating patch and feed network are deposited onto the ceramic substrate using one of several techniques, including screen printing, sputtering, or electroplating.

Screen Printing: This is the most common technique for large - scale production. A stencil with the desired pattern of the patch and feed network is placed over the substrate, and a conductive ink (e.g., copper or silver paste) is forced through the stencil using a squeegee. The substrate is then heated in an oven to cure the ink, forming a solid conductive layer. Screen printing is cost - effective and can be used to produce complex patterns, but it may result in slight variations in the thickness and conductivity of the patch, which can affect the antenna's performance.

Sputtering: Sputtering is a physical vapor deposition (PVD) technique that involves bombarding atarget material (e.g., copper or silver) with high - energy ions in a vacuum chamber. This causes atoms from the target to be ejected (sputtered) and deposited onto the ceramic substrate, forming a thin, uniform conductive layer. Sputtering offers excellent control over the thickness and composition of the patch, resulting in consistent electrical performance. However, it is a slower and more expensive process than screen printing, making it suitable for high - precision, low - volume production.

Electroplating: Electroplating involves immersing the ceramic substrate in an electrolyte solution containing ions of the desired metal (e.g., copper, gold). An electric current is applied to the substrate, causing the metal ions to deposit onto the surface, forming the radiating patch and feed network. Electroplating produces a thick, highly conductive layer with good adhesion to the substrate. It is often used for applications where high conductivity and durability are critical, such as in automotive or industrial environments. However, electroplating requires a conductive seed layer to be deposited on the substrate first, adding an extra manufacturing step.

2.6.3 Assembly and Testing

After the patch and feed network are deposited, the antenna undergoes assembly and testing to ensure it meets the required performance specifications. The assembly process involves attaching the feed connector to the feed network, mounting the ceramic substrate onto a ground plane (if not already integrated), and enclosing the antenna in its protective housing.

Testing is a critical step in the manufacturing process, as it verifies the antenna's electrical performance, mechanical durability, and environmental resistance. Key tests include:

Return Loss Measurement: This test measures the amount of signal reflected back from the antenna, indicating the quality of impedance matching. A return loss of less than - 10 dB is typically required for GNSS RTK applications, meaning that more than 90% of the signal is transmitted to the receiver.

Gain and Radiation Pattern Measurement: The gain of the antenna is measured in an anechoic chamber, which is a room designed to absorb electromagnetic waves, eliminating reflections. The antenna is mounted on a rotating platform, and its response to signals from different angles is measured to determine the radiation pattern. For GNSS RTK applications, a gain of 2 - 5 dBi and a wide beamwidth (typically 60 - 90 degrees in elevation) are desired to track satellites at low elevation angles.

Phase Center Stability Measurement: The phase center stability is measured by comparing the phase of the received signal at different points on the antenna's surface. This test ensures that the phase center remains stable across different frequencies, elevation angles, and azimuth angles, minimizing positioning errors.

Environmental Testing: The antenna is subjected to a series of environmental tests to verify its durability. These tests include temperature cycling (exposing the antenna to extreme temperatures ranging from - 40°C to + 85°C), humidity testing (exposing the antenna to high humidity levels), vibration testing (subjecting the antenna to mechanical vibrations), and waterproof testing (immersing the antenna in water to verify its IP rating).

To understand how a high - precision GNSS RTK ceramic patch antenna operates, it is essential to explore the fundamental principles of electromagnetic wave reception, signal conversion, and phase center stability. These principles work together to ensure that the antenna captures satellite signals accurately and efficiently, enabling the GNSS RTK system to deliver centimeter - level positioning accuracy.

3.1 Electromagnetic Wave Reception

GNSS satellites orbit the Earth at an altitude of approximately 20,000 km, transmitting electromagnetic waves in the L - band frequency range (1 - 2 GHz). These waves travel through the atmosphere, encountering ionospheric and tropospheric delays, before reaching the Earth's surface. The ceramic patch antenna is designed to capture these weak signals (typically - 130 to - 160 dBm) and convert them into usable electrical signals.

The radiating patch of the ceramic patch antenna acts as a resonant structure, tuned to the frequency of the GNSS signals. When an electromagnetic wave from a satellite reaches the patch, it induces an alternating electric field across the patch and the ground plane. This electric field causes electrons in the conductive patch to oscillate, generating an alternating current (AC) in the feed network.

The ceramic substrate plays a crucial role in this process, as its dielectric constant determines the speed at which the electromagnetic wave travels through the antenna. A higher dielectric constant slows down the wave, reducing the physical size of the patch required to resonate at the desired frequency. This miniaturization is essential for integrating the antenna into compact devices, such as UAVs or portable surveying equipment.

3.2 Polarization: Matching Satellite Signals

GNSS satellites transmit signals with right - hand circular polarization (RHCP). This means that the electric field of the wave rotates in a clockwise direction as it travels through space. To efficiently receive these signals, the ceramic patch antenna must also be designed to receive RHCP signals.

The polarization of the ceramic patch antenna is determined by its geometry and feed configuration. For a rectangular patch, RHCP can be achieved by exciting two orthogonal modes (e.g., the TM₁₀ and TM₀₁ modes) with a 90 - degree phase difference. This is typically done using a dual - feed configuration, where two feed lines are connected to the patch at right angles, each providing a signal with a 90 - degree phase shift. Alternatively, a single feed with a phase - shifting network can be used to generate the required phase difference.

Matching the polarization of the antenna to that of the satellite signals is critical for maximizing signal reception. If the antenna is linearly polarized or has the wrong circular polarization (left - hand circular polarization, LHCP), it will only receive a fraction of the satellite signal, leading to reduced gain and increased noise.

3.3 Signal Conversion and Amplification

The alternating current generated in the radiating patch is extremely weak, typically in the microampere range. To make this signal usable by the GNSS receiver, it must be converted into a voltage signal and amplified.

The feed network of the antenna acts as a transformer, converting the high - impedance signal from the patch (typically several hundred ohms) to a low - impedance signal (50 ohms) that is compatible with the receiver. This impedance transformation is achieved through the use of matching networks, such as quarter - wavelength transformers or stub networks, as discussed in Section 2.3.2.

Once the signal is matched to the receiver's impedance, it is transmitted to a low - noise amplifier (LNA) integrated into the antenna or the receiver. The LNA amplifies the weak signal while adding minimal noise, typically having a noise figure of 1 - 2 dB. This is critical for maintaining the signal - to - noise ratio (SNR) of the received signal, which directly affects the accuracy of the GNSS RTK system.

3.4 Phase Center Stability: Ensuring Positioning Accuracy

As mentioned earlier, the phase center of the antenna is the point from which the received satellite signals appear to originate. For high - precision GNSS RTK applications, the phase center must remain stable across different frequencies, elevation angles, and azimuth angles. Any variation in the phase center can introduce errors into the position calculations, as the receiver assumes that all signals are received from a single point.

The phase center stability of a ceramic patch antenna is determined by its design and manufacturing quality. A well - designed patch antenna with a uniform substrate, precise patch dimensions, and symmetric feed configuration will have minimal phase center variation. The use of a high - dielectric - constant substrate also helps to reduce phase center variation, as it concentrates the electromagnetic fields within the substrate, reducing the influence of edge effects.

To further improve phase center stability, some ceramic patch antennas use a choke ring design. A choke ring is a series of concentric rings etched into the ground plane around the patch. These rings act as a filter, absorbing surface waves that can cause phase variations. Choke rings are particularly effective in reducing phase center variation at low elevation angles, where surface waves are more prevalent.

-

High - precision GNSS RTK ceramic patch antennas offer a range of advantages that make them well - suited for high - precision positioning applications. However, they also face several challenges that must be addressed to ensure optimal performance. In this section, we will explore these advantages and challenges in detail.

4.1 Advantages

4.1.1 Compact Size and Low Profile

One of the most significant advantages of ceramic patch antennas is their compact size and low profile. The use of a high - dielectric - constant ceramic substrate allows the antenna to be miniaturized, with dimensions typically ranging from 10 mm × 10 mm to 50 mm × 50 mm. This makes them ideal for integration into small devices, such as UAVs, portable surveying equipment, and wearable devices, where space is limited.

The low profile of ceramic patch antennas (typically 1 - 5 mm thick) also makes them suitable for mounting on flat surfaces, such as the roof of a car, the wing of a UAV, or the body of a surveying instrument. This reduces wind resistance and mechanical stress, improving the durability and reliability of the device.

4.1.2 High Phase Center Stability

As discussed earlier, phase center stability is critical for high - precision GNSS RTK applications. Ceramic patch antennas, when properly designed and manufactured, exhibit excellent phase center stability, with variations typically less than 1 mm across different frequencies, elevation angles, and azimuth angles. This ensures that the position calculations are not affected by phase errors, enabling centimeter - level positioning accuracy.

4.1.3 Wide Frequency Bandwidth

Modern GNSS systems operate across multiple frequency bands, and a high - quality ceramic patch antenna can be designed to cover all these bands simultaneously. For example, a single ceramic patch antenna can cover the GPS L1/L2/L5 bands, GLONASS G1/G2 bands, Galileo E1/E5a/E5b bands, and BeiDou B1/B2/B3 bands. This multi - frequency capability allows the receiver to track signals from multiple GNSS constellations, improving the availability and accuracy of the positioning system.

The wide frequency bandwidth of ceramic patch antennas is achieved through various design techniques, such as stacked patches, U - slot patches, or notched patches. These designs allow the antenna to resonate at multiple frequencies, ensuring that it can receive signals from all relevant GNSS bands.

4.1.4 Good Mechanical Durability

The ceramic substrate used in these antennas is a robust material that can withstand harsh environmental conditions. Ceramic is resistant to extreme temperatures (ranging from - 40°C to + 85°C), high humidity, and mechanical vibrations, making it suitable for outdoor applications. The conductive patch and feed network, typically made of copper or silver, are also resistant to corrosion, ensuring long - term reliability.

In addition, the protective enclosure of the antenna, made of plastic or metal, provides further protection against physical damage and environmental factors. This durability is particularly important for applications such as construction, agriculture, and mining, where the antenna may be exposed to rough handling and adverse weather conditions.

4.1.5 Low Cost and High Volume Production

Ceramic patch antennas can be manufactured using cost - effective techniques such as screen printing, which is suitable for high - volume production. The materials used (e.g., alumina ceramic, copper) are also relatively inexpensive, making ceramic patch antennas more affordable than other high - precision antenna types, such as helical or phased array antennas.

This low cost and high - volume production capability make ceramic patch antennas ideal for mass - market applications, such as consumer electronics, automotive navigation systems, and precision agriculture equipment.

4.2 Challenges

4.2.1 Limited Gain and Beamwidth

Compared to other antenna types, such as helical or parabolic antennas, ceramic patch antennas have relatively low gain (typically 2 - 5 dBi) and a narrower beamwidth (typically 60 - 90 degrees in elevation). This can limit their performance in areas with poor satellite visibility, such as urban canyons or dense forests, where signals from low - elevation satellites may be blocked.

To address this challenge, some ceramic patch antennas use a high - gain design, such as a stacked patch or a patch array. A stacked patch antenna consists of multiple patches stacked on top of each other, increasing the gain by 1 - 2 dBi. A patch array consists of multiple patches arranged in a grid, further increasing the gain and beamwidth. However, these designs increase the size and cost of the antenna, making them less suitable for compact applications.

4.2.2 Sensitivity to Environmental Factors

While ceramic patch antennas are durable, they are still sensitive to certain environmental factors, such as temperature variations and electromagnetic interference (EMI).

Temperature variations can cause the ceramic substrate to expand or contract, changing its dielectric constant and the dimensions of the radiating patch. This can shift the antenna's resonant frequency, reducing its performance. To mitigate this, manufacturers use temperature - stable ceramic materials, such as alumina or zirconia, and design the antenna to have a wide frequency bandwidth, ensuring that it remains resonant even with temperature - induced frequency shifts.

EMI from other electronic devices, such as radios, cell phones, or power lines, can also interfere with the satellite signals received by the antenna. This can increase the noise floor, reducing the SNR and degrading the positioning accuracy. To reduce EMI, ceramic patch antennas are often enclosed in a metal housing, which acts as a shield. In addition, the feed network is designed to filter out unwanted signals, ensuring that only GNSS signals are transmitted to the receiver.

4.2.3 Multipath Interference

Multipath interference occurs when satellite signals reach the antenna via multiple paths, such as direct and reflected paths. This can cause the received signal to be distorted, leading to errors in the position calculations. Ceramic patch antennas are susceptible to multipath interference, particularly in urban environments where signals can be reflected off buildings, walls, or other structures.

To reduce multipath interference, various techniques are used, such as:

Choke Ring Design: As mentioned earlier, a choke ring etched into the ground plane can absorb surface waves, reducing the impact of reflected signals.

Low - Elevation Nulling: Some antennas are designed to have a null (a reduction in gain) at low elevation angles, where multipath interference is more prevalent. This reduces the reception of reflected signals, improving the accuracy of the positioning system.

Signal Processing Algorithms: The GNSS receiver can use signal processing algorithms, such as the Least Squares method or Kalman filtering, to detect and eliminate multipath signals. However, these algorithms add complexity to the receiver and may increase power consumption.

4.2.4 Manufacturing Tolerances

The performance of a ceramic patch antenna is highly dependent on its manufacturing tolerances. Even small variations in the dimensions of the patch, the thickness of the substrate, or the conductivity of the patch material can significantly affect the antenna's gain, impedance matching, and phase center stability.

To address this challenge, manufacturers use advanced manufacturing techniques, such as laser cutting or precision molding, to ensure that the antenna components meet tight tolerances. In addition, each antenna undergoes rigorous testing to verify its performance, ensuring that only those that meet the required specifications are shipped to customers. However, these measures increase the cost and complexity of the manufacturing process.

-

5.1 Applications

High - precision GNSS RTK ceramic patch antennas are used in a wide range of applications that require centimeter - level positioning accuracy. Their compact size, low profile, and high performance make them ideal for use in various industries, including surveying and mapping, agriculture, automotive, and aerospace.

5.1.1 Surveying and Mapping

In surveying and mapping, accurate positioning is essential for creating detailed topographic maps, marking property boundaries, and aligning infrastructure projects. GNSS RTK systems equipped with ceramic patch antennas are widely used in this field, as they can provide centimeter - level accuracy in real - time.

Surveyors use portable GNSS RTK receivers with integrated ceramic patch antennas to collect data points in the field. The antenna's compact size and low profile make it easy to carry, while its high phase center stability ensures that the data points are accurate. The multi - frequency capability of the antenna allows the receiver to track signals from multiple GNSS constellations, improving the availability of satellite signals even in remote areas.

In addition to land surveying, ceramic patch antennas are also used in hydrographic surveying, where they are mounted on boats or ships to map the ocean floor. The antenna's waterproof enclosure and durability make it suitable for use in marine environments.

5.1.2 Precision Agriculture

Precision agriculture is a rapidly growing field that uses technology to optimize crop production and reduce waste. GNSS RTK systems with ceramic patch antennas are used to guide agricultural machinery, such as tractors, harvesters, and sprayers, with pinpoint accuracy.

Farmers use GNSS RTK - enabled tractors to plow, plant, and harvest crops in straight lines, reducing overlap and increasing efficiency. The ceramic patch antenna, mounted on the roof of the tractor, provides centimeter - level positioning accuracy, ensuring that the machinery follows the desired path. The multi - frequency capability of the antenna allows the receiver to track signals even in areas with dense vegetation, where satellite visibility may be limited.

In addition, GNSS RTK systems are used to create variable - rate application maps, which allow farmers to apply fertilizers, pesticides, and irrigation based on the specific needs of each area of the field. This reduces the use of chemicals and water, lowering costs and minimizing environmental impact.

5.1.3 Autonomous Vehicles

Autonomous vehicles rely on high - precision positioning systems to navigate safely and efficiently. GNSS RTK systems with ceramic patch antennas are a key component of these positioning systems, providing centimeter - level accuracy in real - time.

The ceramic patch antenna is mounted on the roof of the autonomous vehicle, where it can receive signals from multiple GNSS constellations. The antenna's compact size and low profile make it suitable for integration into the vehicle's design, while its high phase center stability ensures that the positioning data is accurate. The multi - frequency capability of the antenna allows the receiver to track signals even in urban environments, where buildings and other structures can block satellite signals.

In combination with other sensors, such as lidar, cameras, and radar, the GNSS RTK system provides the autonomous vehicle with a comprehensive understanding of its environment, enabling it to make informed decisions about navigation and obstacle avoidance.

5.1.4 Aerospace and Defense

In the aerospace and defense industry,high - precision positioning is critical for a wide range of applications, including satellite navigation, missile guidance, and unmanned aerial systems (UAS). Ceramic patch antennas are well - suited for these applications due to their compact size, high performance, and durability.

In satellite navigation systems, ceramic patch antennas are used in both satellites and ground stations. On satellites, the antennas are mounted on the exterior of the spacecraft, where they receive and transmit signals to and from the ground. The compact size and low weight of ceramic patch antennas are essential for reducing the overall weight and volume of the satellite, which lowers launch costs. The high phase center stability of the antennas ensures that the satellite's position can be accurately determined, enabling precise orbit control.

In missile guidance systems, ceramic patch antennas are used to provide real - time positioning data to the missile's guidance system. The antenna's high precision and fast response time allow the missile to navigate to its target with extreme accuracy. The durability of the antenna is also critical, as it must withstand the high acceleration forces and extreme temperatures experienced during missile launch and flight.

UAS, also known as drones, are widely used in the aerospace and defense industry for reconnaissance, surveillance, and combat missions. Ceramic patch antennas are integrated into UAS to provide high - precision positioning data, enabling the drone to navigate to specific locations and perform its mission with accuracy. The compact size and low profile of the antenna make it suitable for integration into the drone's airframe, while its multi - frequency capability allows it to track signals from multiple GNSS constellations, ensuring reliable positioning even in remote or hostile environments.

5.2 Future Trends

As technology continues to advance, the demand for higher precision, smaller size, and greater functionality in GNSS RTK systems is expected to grow. This will drive the development of new and improved ceramic patch antennas with enhanced performance characteristics. In this section, we will explore some of the key future trends in the development of high - precision GNSS RTK ceramic patch antennas.

5.2.1 Enhanced Multi - Constellation and Multi - Frequency Support

With the continued expansion of GNSS constellations, such as the completion of Galileo and the expansion of BeiDou, future ceramic patch antennas will need to support an even wider range of frequencies and constellations. This will require the development of new antenna designs that can resonate at multiple frequencies simultaneously, while maintaining high performance across all bands.

One promising approach is the use of metamaterials in the antenna design. Metamaterials are artificial materials with unique electromagnetic properties that are not found in nature. By incorporating metamaterials into the ceramic substrate or radiating patch, it is possible to design antennas with a wider frequency bandwidth and improved performance. For example, metamaterial - based antennas can be designed to have a negative dielectric constant, which allows them to resonate at multiple frequencies without increasing the size of the antenna.

Another approach is the use of advanced signal processing techniques to enhance the antenna's multi - frequency capability. For example, adaptive filtering algorithms can be used to separate signals from different frequency bands, improving the antenna's ability to track multiple GNSS constellations simultaneously.

5.2.2 Miniaturization and Integration

The trend towards miniaturization of electronic devices is expected to continue, driving the development of even smaller ceramic patch antennas. This will require the use of new materials and manufacturing techniques to reduce the size of the antenna without sacrificing performance.

One promising material for miniaturization is low - temperature co - fired ceramic (LTCC) technology. LTCC allows multiple ceramic layers to be stacked and fired at a low temperature, enabling the integration of passive components, such as capacitors and inductors, into the antenna substrate. This reduces the overall size of the antenna system, making it suitable for integration into microelectronic devices, such as wearable sensors and Internet of Things (IoT) devices.

Another approach to miniaturization is the use of 3D printing technology. 3D printing allows the creation of complex antenna geometries that are difficult or impossible to manufacture using traditional techniques. This can be used to design smaller, more efficient ceramic patch antennas with unique radiation patterns and performance characteristics.

In addition to miniaturization, future ceramic patch antennas will be more tightly integrated with other components of the GNSS RTK system, such as the receiver, LNA, and signal processing unit. This integration will reduce the overall size and weight of the system, improve signal integrity, and lower power consumption. For example, the antenna and LNA can be integrated into a single package, reducing the length of the transmission line between them and minimizing signal loss.

5.2.3 Improved Environmental Resistance

As GNSS RTK systems are increasingly used in harsh environments, such as extreme temperatures, high humidity, and corrosive atmospheres, future ceramic patch antennas will need to have even greater environmental resistance. This will require the development of new materials and protective coatings that can withstand these harsh conditions.

One area of research is the use of advanced ceramic materials, such as silicon carbide (SiC) and aluminum nitride (AlN), which have superior thermal and chemical stability compared to traditional ceramic materials. SiC has a high melting point (2730°C) and excellent corrosion resistance, making it suitable for use in high - temperature and corrosive environments. AlN has a high thermal conductivity, which allows it to dissipate heat more effectively, reducing the impact of temperature variations on the antenna's performance.

Another approach is the development of new protective coatings, such as diamond - like carbon (DLC) coatings. DLC coatings have excellent hardness, wear resistance, and chemical stability, making them ideal for protecting the antenna from physical damage and environmental corrosion. These coatings can be applied to the surface of the ceramic substrate and radiating patch, improving the antenna's durability and lifespan.

5.2.4 Artificial Intelligence (AI) - Enabled Performance Optimization

The integration of AI into GNSS RTK systems is expected to revolutionize the performance of ceramic patch antennas. AI algorithms can be used to optimize the antenna's performance in real - time, adapting to changing environmental conditions and improving the accuracy and reliability of the positioning system.

One application of AI is in the optimization of the antenna's radiation pattern. AI algorithms can analyze the satellite signal environment and adjust the antenna's radiation pattern to maximize the reception of desired signals and minimize the impact of interference. For example, if the antenna is in an urban environment with a lot of multipath interference, the AI algorithm can adjust the radiation pattern to focus on direct signals from high - elevation satellites, reducing the impact of reflected signals.

Another application of AI is in the prediction and mitigation of environmental effects on the antenna's performance. AI algorithms can analyze historical data on temperature, humidity, and other environmental factors, and predict how these factors will affect the antenna's resonant frequency, gain, and phase center stability. The algorithm can then adjust the antenna's parameters, such as the bias voltage of the LNA or the capacitance of the matching network, to compensate for these effects, ensuring that the antenna maintains optimal performance.

5.2.5 Energy Harvesting Integration

With the growing demand for low - power and self - powered electronic devices, future ceramic patch antennas may be integrated with energy harvesting systems. Energy harvesting systems can convert ambient energy, such as solar energy, electromagnetic energy, or thermal energy, into electrical energy, which can be used to power the antenna and other components of the GNSS RTK system.

For example, a ceramic patch antenna could be integrated with a solar cell, which converts sunlight into electrical energy. The solar cell could be mounted on the surface of the antenna's enclosure, providing a continuous source of power for the antenna's LNA and other electronic components. This would eliminate the need for batteries, reducing the size and weight of the system and increasing its lifespan.

Another approach is the integration of electromagnetic energy harvesting systems. These systems can capture electromagnetic energy from the surrounding environment, such as radio waves or Wi - Fi signals, and convert it into electrical energy. This could be particularly useful in urban environments, where there is a high density of electromagnetic signals.

Conclusion

High - precision GNSS RTK ceramic patch antennas have emerged as a critical component in a wide range of applications that require centimeter - level positioning accuracy. Their unique combination of compact size, low profile, high phase center stability, wide frequency bandwidth, and good mechanical durability makes them well - suited for use in surveying and mapping, precision agriculture, autonomous vehicles, and aerospace and defense.

In this in - depth exploration, we have examined the design and construction of ceramic patch antennas, including the selection of materials for the substrate, radiating patch, and feed network, as well as the manufacturing processes used to produce these antennas. We have also explored the working principles of ceramic patch antennas, including electromagnetic wave reception, polarization matching, signal conversion and amplification, and phase center stability.

Furthermore, we have discussed the advantages and challenges of ceramic patch antennas, highlighting their compact size, high phase center stability, and low cost, as well as their limited gain and beamwidth, sensitivity to environmental factors, and susceptibility to multipath interference. We have also explored the wide range of applications of these antennas and the key future trends in their development, including enhanced multi - constellation and multi - frequency support, miniaturization and integration, improved environmental resistance, AI - enabled performance optimization, and energy harvesting integration.

As technology continues to advance, the performance of high - precision GNSS RTK ceramic patch antennas will continue to improve, enabling new and innovative applications in various industries. The development of new materials, manufacturing techniques, and signal processing algorithms will allow these antennas to meet the growing demand for higher precision, smaller size, and greater functionality in GNSS RTK systems.

In conclusion, high - precision GNSS RTK ceramic patch antennas are a vital technology that will play a key role in the future of positioning and navigation systems. Their ability to provide accurate, reliable, and real - time positioning data will continue to drive innovation in a wide range of industries, improving efficiency, reducing costs, and enhancing safety. As we look to the future, it is clear that ceramic patch antennas will remain at the forefront of GNSS RTK technology, enabling new possibilities and transforming the way we live, work, and travel.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)