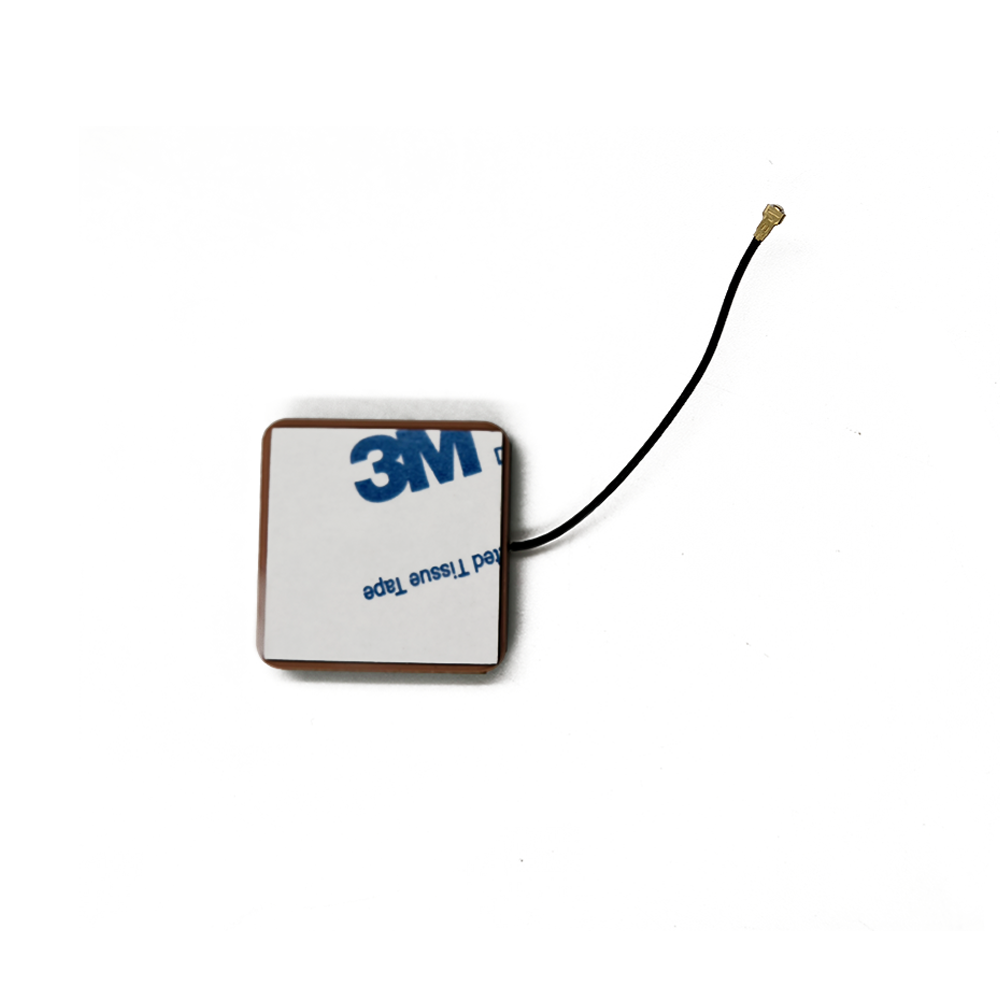

High - precision GNSS ceramic patch antennas find applications in a wide range of fields, and there are several exciting future trends on the horizon.

5.1 Current Applications

Autonomous Driving: In the automotive industry, high - precision GNSS ceramic patch antennas are crucial for autonomous driving. The accurate positioning provided by these antennas is essential for the vehicle to navigate safely, follow traffic lanes, and avoid collisions. Autonomous vehicles rely on real - time and highly precise location information to make decisions such as accelerating, braking, and turning. The use of multi - constellation and multi - band antennas in autonomous driving systems allows for more reliable positioning, even in challenging environments.

Precision Agriculture: Precision agriculture is another area where high - precision GNSS ceramic patch antennas are widely used. Farmers use these antennas to precisely control the application of fertilizers, pesticides, and water. By knowing the exact location of different areas in the field, farmers can optimize the use of resources, reducing waste and environmental impact while increasing crop yields. GNSS - enabled tractors and other agricultural equipment can be guided with high accuracy, ensuring efficient tilling, planting, and harvesting.

Surveying and Mapping: In the field of surveying and mapping, high - precision GNSS ceramic patch antennas are used to accurately measure the positions of points on the Earth's surface. Surveyors use these antennas to create detailed maps, establish property boundaries, and monitor land deformation. The centimeter - level accuracy provided by these antennas is essential for ensuring the reliability of the survey data.

Aerospace and Aviation: In aerospace and aviation, high - precision GNSS ceramic patch antennas are used for navigation and positioning. Aircraft rely on accurate GNSS signals to determine their position during takeoff, flight, and landing. These antennas also play a role in unmanned aerial vehicles (UAVs), enabling them to fly along pre - programmed routes with high precision.

5.2 Future Trends

Increased Integration with Other Technologies: In the future, high - precision GNSS ceramic patch antennas are likely to be more closely integrated with other technologies. For example, they may be combined with inertial navigation systems (INS) and sensors such as lidar and cameras in autonomous vehicles to provide even more accurate and reliable positioning information. The integration of GNSS with 5G and other wireless communication technologies may also open up new applications, such as real - time data transfer for remote monitoring and control.

Expansion of GNSS Constellations and Bands: New GNSS constellations are being developed, and existing ones are being expanded. This will provide more satellites and more frequency bands for high - precision GNSS ceramic patch antennas to receive signals from. The use of additional frequency bands can further improve the accuracy and reliability of the antennas by reducing errors due to ionospheric and tropospheric delays.

Improved Antenna Performance through Advanced Materials and Designs: Research into new ceramic materials and antenna designs is ongoing. Future high - precision GNSS ceramic patch antennas may be made from materials with even better electrical properties, allowing for further miniaturization and improved performance. Advanced designs, such as reconfigurable antennas that can adapt to different environmental conditions, may also become more prevalent.

Growth in New Applications: As the performance of high - precision GNSS ceramic patch antennas continues to improve and their cost decreases, new applications are likely to emerge. For example, in the Internet of Things (IoT) field, these antennas could be used to provide accurate location information for a wide range of connected devices, enabling applications such as asset tracking, smart city management, and environmental monitoring.

Conclusion

High - precision GNSS ceramic patch antennas have come a long way in their development and have become an essential component in many modern - day applications. Their ability to provide accurate positioning information, combined with advantages such as miniaturization, durability, and low power consumption, makes them highly valuable in fields ranging from autonomous driving to precision agriculture.

Despite the challenges they face, such as multipath interference and signal blockage, continuous research and development efforts are being made to address these issues. The future of high - precision GNSS ceramic patch antennas looks promising, with trends such as increased integration with other technologies, expansion of GNSS constellations and bands, and the development of advanced materials and designs set to drive further innovation.

From a technical perspective, the ongoing refinement of manufacturing processes—such as the optimization of ceramic co-firing techniques and the advancement of metallization methods—will continue to enhance the consistency and performance of these antennas. This, in turn, will reduce production costs, making high-precision GNSS ceramic patch antennas more accessible to a broader range of applications, including cost-sensitive sectors like consumer electronics and small-scale IoT devices.

In terms of industry impact, the role of these antennas in enabling critical technologies cannot be overstated. In autonomous driving, for example, as vehicles become more reliant on real-time, centimeter-level positioning to navigate complex urban environments, the reliability and accuracy of high-precision GNSS ceramic patch antennas will directly influence the safety and widespread adoption of self-driving systems. Similarly, in precision agriculture, the ability of these antennas to support variable-rate technology will contribute to sustainable farming practices, helping to address global challenges such as food security and environmental degradation.

Looking ahead, the integration of high-precision GNSS ceramic patch antennas with emerging technologies like artificial intelligence (AI) and machine learning (ML) presents exciting opportunities. AI-driven signal processing algorithms could further mitigate multipath interference and signal blockage, adapting in real time to changing environmental conditions. For instance, ML models could learn to identify and filter out interference patterns specific to urban canyons or dense forests, ensuring consistent positioning accuracy even in the most challenging scenarios.

Moreover, as the demand for seamless connectivity and location-based services grows, high-precision GNSS ceramic patch antennas will play a key role in the development of smart cities. From intelligent traffic management systems that rely on accurate vehicle positioning to optimize traffic flow, to asset tracking solutions that monitor the movement of goods in real time, these antennas will serve as the backbone of a more connected and efficient urban infrastructure.

It is also important to recognize the collaborative nature of advancements in this field. The success of high-precision GNSS ceramic patch antennas depends not only on innovations in antenna design and materials but also on progress in GNSS satellite technology, receiver hardware, and software algorithms. As satellite constellations like BeiDou-3 and Galileo expand their coverage and improve signal quality, and as receivers become more efficient at processing complex signals, the performance of these antennas will be further amplified.

In conclusion, high-precision GNSS ceramic patch antennas represent a critical intersection of materials science, electrical engineering, and satellite technology. Their evolution has been driven by the growing need for accurate, reliable, and compact positioning solutions across industries, and their future will be shaped by ongoing technological advancements and emerging application demands. As research continues to address existing challenges and unlock new capabilities, these antennas will remain indispensable tools in enabling the next generation of location-dependent technologies, contributing to a more precise, efficient, and connected world.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)