Applications

The built-in RTK GPS ceramic antenna has a wide range of applications across multiple industries. In the automotive industry, it is used in autonomous vehicles for precise positioning, enabling the vehicle to accurately navigate roads, detect obstacles, and follow traffic rules. In advanced driver - assistance systems (ADAS), it provides high - accuracy location data for functions such as lane - keeping assist and adaptive cruise control.

In precision agriculture, the antenna plays a vital role. Farmers can use RTK - enabled devices to precisely map fields, apply fertilizers and pesticides with high accuracy, and monitor crop growth. This not only improves crop yields but also reduces the use of chemicals, making agriculture more sustainable.

For surveying and mapping, the built-in RTK GPS ceramic antenna offers a more efficient and accurate alternative to traditional methods. Surveyors can quickly and accurately measure land boundaries, create detailed topographic maps, and monitor construction sites. In the construction industry, it helps in the precise placement of structures, ensuring that buildings and infrastructure are constructed according to design specifications.

In the drone industry, RTK - equipped drones are used for aerial photography, surveying, and delivery services. The high - accuracy positioning provided by the antenna allows drones to fly precise routes, capture high - quality images, and deliver packages to specific locations with greater reliability.

Future Trends

Looking ahead, several future trends are emerging for built-in RTK GPS ceramic antennas. One trend is the integration of multiple satellite navigation systems. In addition to GPS, other global navigation satellite systems (GNSS) such as GLONASS, Galileo, and BeiDou are becoming more prevalent. Future antennas are likely to be designed to receive signals from multiple GNSS simultaneously, providing more accurate and reliable positioning information, especially in challenging environments.

Another trend is the development of more compact and energy-efficient RTK systems. As technology advances, there will be a push to further miniaturize the RTK components while reducing power consumption. This will make it possible to integrate RTK GPS ceramic antennas into even smaller devices, such as wearable sensors and miniature drones.

The integration of artificial intelligence (AI) and machine learning (ML) with RTK systems is also an emerging trend. AI and ML algorithms can be used to optimize the RTK positioning process, improve signal processing, and handle complex environmental conditions more effectively. For example, AI can be used to predict and mitigate the effects of interference, enhancing the overall performance of the RTK GPS ceramic antenna.

There is also a growing interest in using RTK technology for indoor positioning. While traditional GPS is mainly for outdoor use, research is underway to adapt RTK principles for indoor environments, such as large warehouses, airports, and shopping malls. Built-in RTK GPS ceramic antennas may play a key role in this development, enabling accurate indoor positioning for applications like asset tracking and navigation within buildings.

Conclusion

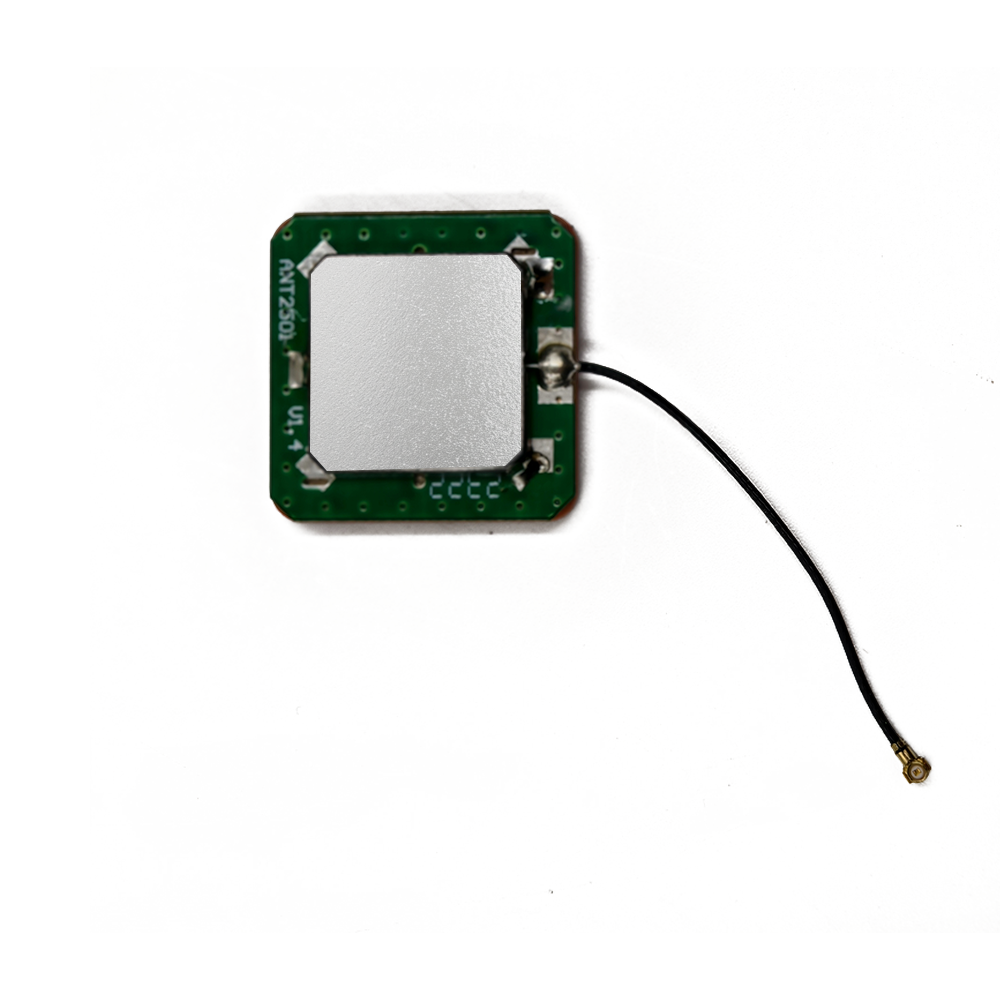

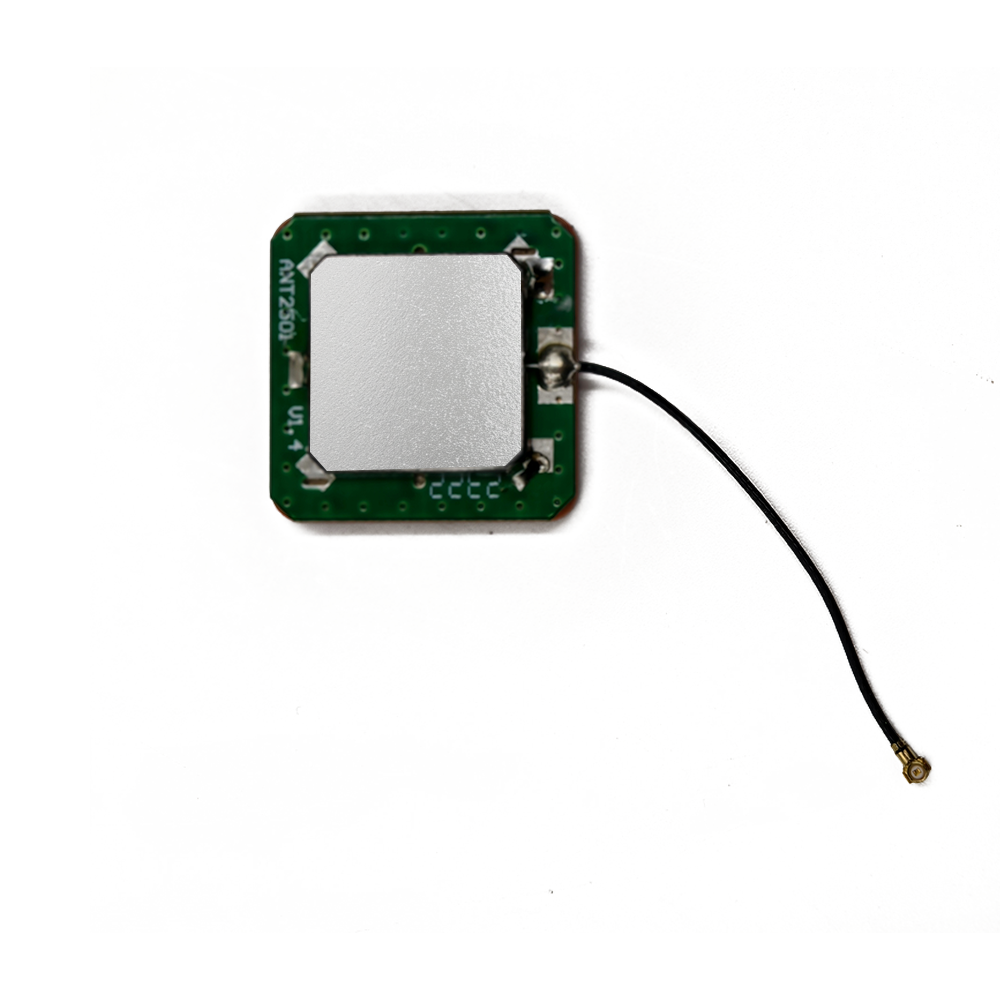

In conclusion, the built-in RTK GPS ceramic antenna represents a powerful combination of high - accuracy RTK positioning technology and the advantages of ceramic antenna materials. Its ability to provide centimeter - level accuracy, compact size, durability, and excellent integration capabilities has made it an essential component in various industries.

However, the challenges associated with the complexity of the RTK system, interference, environmental factors, and manufacturing consistency need to be addressed for further widespread adoption. Overcoming these challenges will require continuous research and development efforts from both academia and industry.

Looking to the future, with the emergence of trends such as multi - GNSS integration, miniaturization, the integration of AI and ML, and indoor positioning applications, the built-in RTK GPS ceramic antenna is poised to play an even more significant role in enabling accurate and reliable location - based services. As technology continues to evolve, these antennas will open up new possibilities for innovation and growth in a wide range of sectors, from transportation and agriculture to construction and beyond.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)