the core of this antenna’s design

At the core of this antenna’s design is its IPX connectivity, a feature that aligns perfectly with the miniaturization demands of RTK-enabled devices. IPX (U.FL) connectors are among the smallest RF interfaces available, measuring just 3mm in diameter, making them ideal for built-in applications where space is a premium. Unlike bulkier connectors such as SMA, which can dominate the footprint of small devices, IPX connectors allow the antenna to be integrated into tight spaces—whether on a drone’s flight controller PCB or inside a compact industrial sensor. The push-pull locking mechanism of IPX connectors ensures a secure, vibration-resistant connection, a critical attribute for RTK systems where even momentary signal loss can disrupt centimeter-level positioning.

Beyond space efficiency, IPX connectors maintain exceptional electrical performance, with insertion loss typically below 0.3 dB at GNSS frequencies. This low loss is vital for RTK, as the carrier-phase signals used for high-precision calculations are extremely weak—often 20-30 dB weaker than the code-phase signals used in standard GPS. By minimizing signal degradation, the IPX interface ensures that the antenna’s output retains the phase integrity required for RTK algorithms to resolve position errors down to centimeters. For OEMs integrating RTK into small devices, the IPX connector’s compatibility with standard GNSS modules simplifies design, reducing the need for custom hardware and accelerating time-to-market.

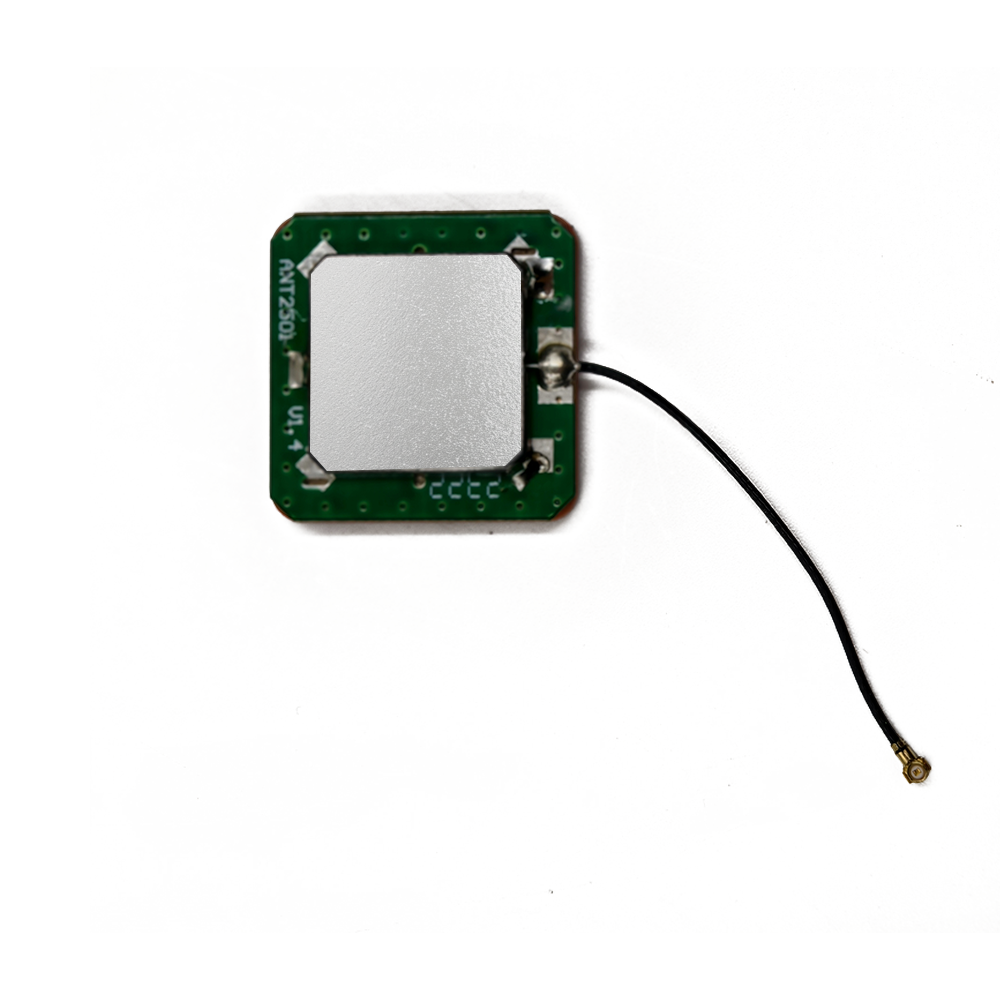

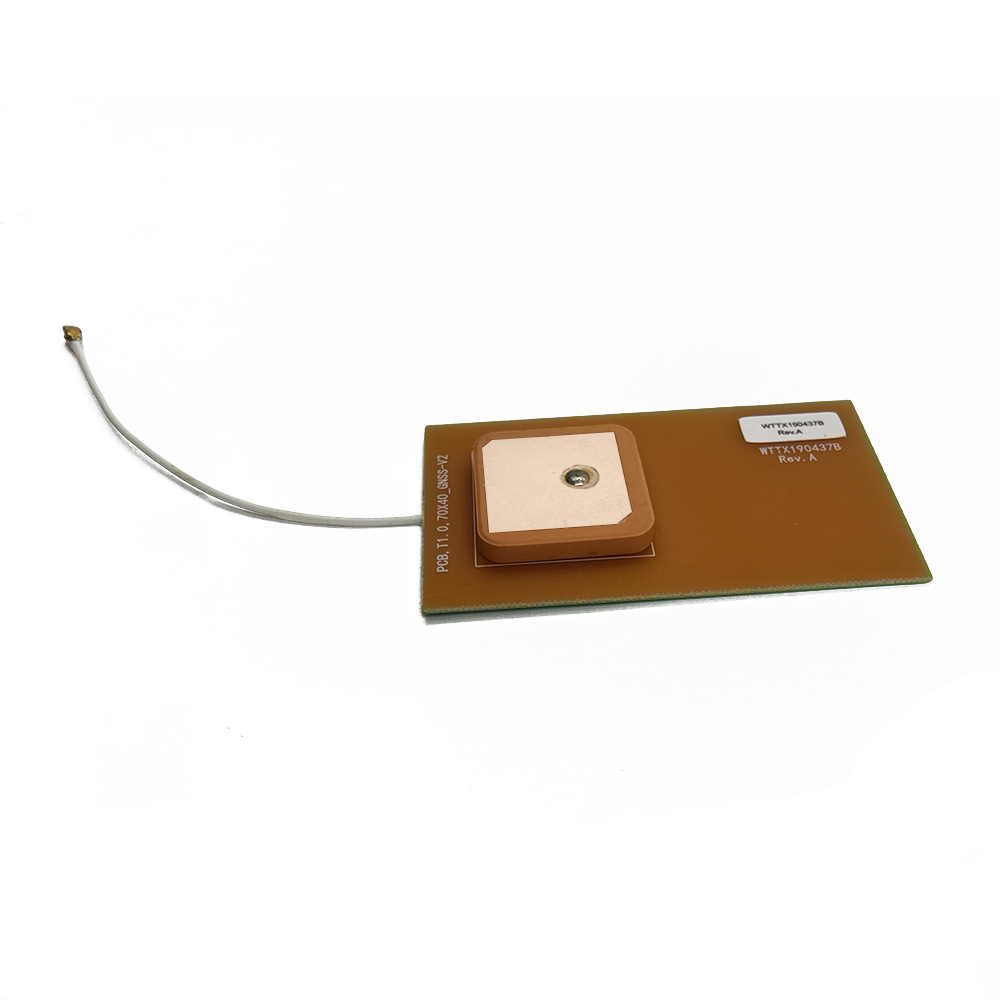

The antenna’s material composition—ceramic paired with a PCB (FR4)—is a masterclass in balancing performance and compactness. Ceramic is the cornerstone of its efficiency, boasting a high dielectric constant (20-40) that allows the antenna to resonate at GNSS frequencies within a tiny footprint. The dielectric constant reduces the wavelength of RF signals, enabling the antenna to achieve optimal performance at 1575 MHz (GPS L1) and 1602 MHz (GLONASS G1) despite its 25x25mm size. This miniaturization is critical for built-in RTK applications, where the antenna must coexist with processors, batteries, and other components without compromising accuracy.

The FR4 PCB serves dual roles: as a structural base and a precision ground plane. FR4, a glass-reinforced epoxy laminate, provides mechanical stability to withstand manufacturing stresses and operational vibrations, ensuring consistent performance across device lifetimes. As a ground plane, it shapes the antenna’s radiation pattern, focusing energy upward toward the sky to maximize satellite signal reception while minimizing interference with internal electronics. This directional focus is particularly important for RTK, as it reduces multipath errors caused by signals reflecting off nearby surfaces—a common issue in embedded environments. The PCB also facilitates seamless integration of the IPX connector and coaxial cable, ensuring that the antenna can be mass-produced with tight tolerances, a necessity for maintaining RTK precision across production runs.

The antenna employs linear polarization, a deliberate choice optimized for the fixed orientations of built-in RTK applications. Unlike circular polarization, which excels in dynamic environments where the antenna’s orientation changes (e.g., handheld devices), linear polarization delivers superior efficiency when aligned with incoming satellite signals. In RTK systems, the antenna is typically mounted in a fixed position—whether on a drone’s frame, a robot’s chassis, or a sensor’s enclosure—allowing for precise calibration during installation. This alignment ensures that the antenna captures maximum signal strength from satellites, a critical factor for RTK’s carrier-phase measurements, which rely on strong, stable signals to resolve centimeter-level differences.

Linear polarization also simplifies the antenna’s design, reducing phase noise and improving signal purity—key attributes for RTK. While circular polarization introduces slight phase variations that can complicate carrier-phase tracking, linear polarization provides a more stable reference, enabling the receiver to lock onto satellite signals with greater precision. For OEMs, this translates to more reliable RTK performance in fixed-mount applications, from agricultural sensors mapping crop health to robotic arms navigating factory floors with sub-centimeter accuracy.

The antenna operates within a frequency band

The antenna operates within a frequency band of 1560-1602 MHz, a range carefully selected to cover the core frequencies of major GNSS constellations essential for RTK:

GPS L1 (1575.42 MHz): The primary civilian frequency, offering global coverage and serving as the backbone of most RTK systems.

BeiDou B1 (1561.098 MHz): Enhances coverage in the Asia-Pacific region, adding redundancy and improving satellite visibility in challenging environments.

GLONASS G1 (1602 MHz): Strengthens performance in high-latitude regions, where GPS signals may be weaker, ensuring global RTK reliability.

This multi-constellation support is a cornerstone of RTK accuracy, as it increases the number of visible satellites, reduces the risk of signal blockages, and enables cross-constellation error correction. For example, in urban canyons where GPS signals are obstructed by skyscrapers, BeiDou or GLONASS signals captured by the antenna can maintain RTK lock, ensuring uninterrupted high-precision positioning. This versatility makes the antenna suitable for global applications, from European smart cities to Asian logistics hubs.

The antenna delivers a typical gain of 1.5 dB, a specification that reflects its efficiency in converting received signal energy into usable power for RTK processing. While this gain may seem modest compared to larger external RTK antennas (which often offer 5-8 dB gain), it is optimized for the antenna’s compact size and built-in constraints. Excessive gain in small antennas can narrow the radiation pattern, limiting reception from low-elevation satellites—a critical drawback in RTK, where all available satellites contribute to positioning accuracy. The 1.5 dB gain ensures a broad radiation pattern, allowing the antenna to capture signals from satellites across elevations as low as 10 degrees, which is essential for maintaining RTK lock in urban or forested environments.

This gain is achieved through meticulous design of the ceramic patch’s dimensions and its interaction with the FR4 ground plane. The ceramic’s high dielectric constant focuses energy without overcome narrowing the beam, while the ground plane ensures that radiation is directed upward, minimizing absorption by the device’s housing. In RTK terms, this translates to a higher number of tracked satellites and more robust carrier-phase measurements, both of which are critical for achieving centimeter-level accuracy.

The antenna’s VSWR (Voltage Standing Wave Ratio) specifications—2.0 at 1575 MHz and 3.5 at 1602 MHz—reflect its optimized performance across its frequency band. VSWR measures how efficiently the antenna transfers energy to the receiver, with lower values indicating better matching. At 1575 MHz (GPS L1), a VSWR of 2.0 is excellent, ensuring that over 90% of the received signal is transferred to the RTK receiver with minimal reflection. This is critical for preserving the integrity of GPS L1 signals, which are the primary input for most RTK systems.

At 1602 MHz (GLONASS G1), the higher VSWR of 3.5 is acceptable given GLONASS’s supplementary role in many RTK setups. This tradeoff allows the antenna to maintain a compact size while still providing functional GLONASS reception, ensuring that the system can leverage multiple constellations when needed. For RTK, which relies on redundant satellite data to resolve ambiguities, this balance between GPS performance and multi-constellation support is essential.

With an impedance of 50 ohms, the antenna adheres to the industry standard for RF systems, ensuring seamless compatibility with RTK receivers, GNSS modules, and coaxial cables. Impedance matching is critical for RTK, as mismatched impedances can cause signal reflections that corrupt the carrier-phase measurements used for high-precision positioning. A 50-ohm impedance is universally adopted in GNSS and RTK hardware, allowing the antenna to integrate with off-the-shelf receivers from leading manufacturers. This compatibility simplifies the design process for OEMs, enabling them to pair the antenna with proven RTK chipsets without custom matching networks—a key advantage in reducing development time and costs.

The antenna’s operating temperature range of -20°C to +85°C and storage temperature range of -20°C to +65°C ensure reliable performance in the diverse environments where RTK systems are deployed. From freezing agricultural fields to sun-baked construction sites, the antenna’s components are engineered to withstand extreme temperatures without degradation. The ceramic patch’s dielectric properties remain stable across this range, preventing shifts in resonant frequency that could disrupt RTK lock. The FR4 PCB and IPX connector also resist thermal stress, ensuring mechanical integrity even after repeated temperature cycles.

This temperature resilience is particularly important for built-in RTK antennas, which are often enclosed in device housings where heat from processors or batteries can raise internal temperatures. By maintaining performance up to 85°C, the antenna ensures that RTK accuracy is preserved even in high-power devices such as drone flight controllers or industrial robots operating in warm environments.

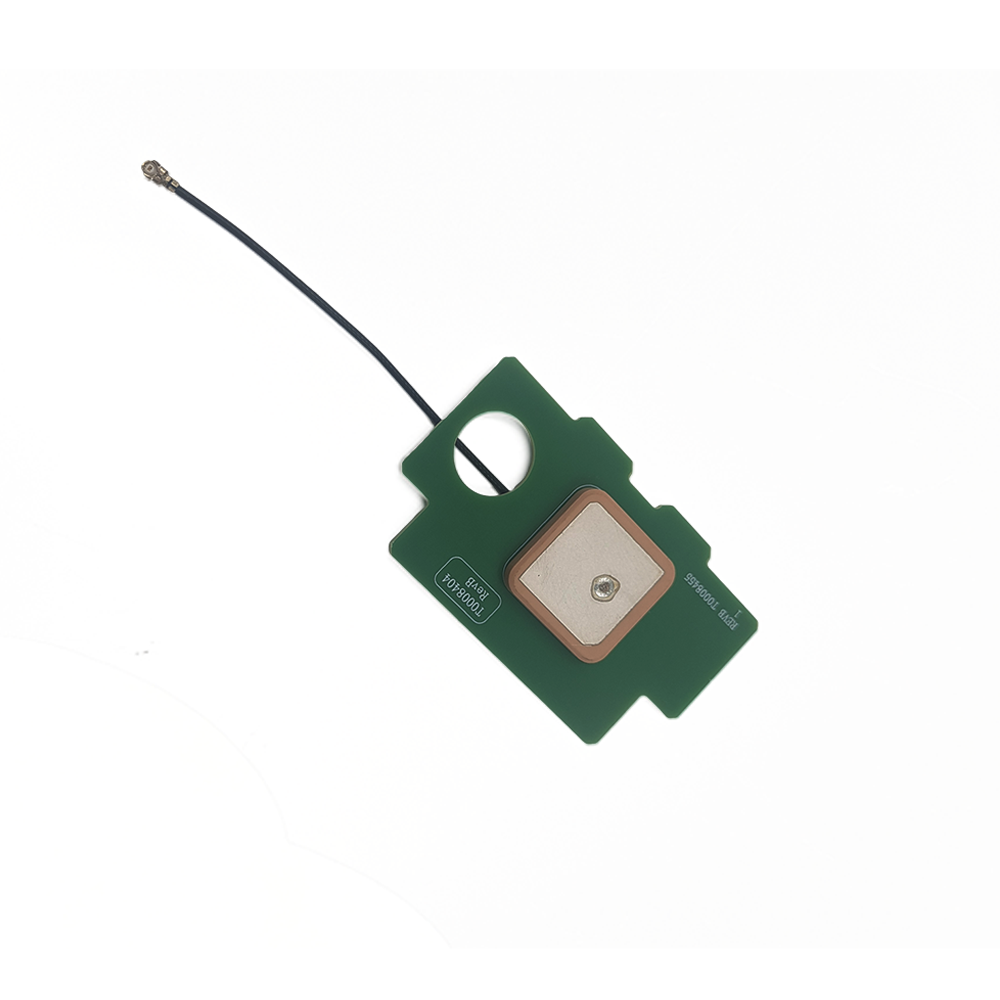

With a size of 25 x 25 x 4mm, the antenna sets a new standard for miniaturized RTK technology. This compact footprint allows it to be integrated into devices where traditional RTK antennas—often 50mm or larger in diameter—would be impractical. For example, in a compact drone designed for precision agriculture, the antenna fits within the drone’s body without increasing drag or weight, preserving flight time while enabling centimeter-level mapping. In a wearable RTK tracker for surveyors, the small size ensures comfort without sacrificing accuracy.

The 4mm thickness is equally critical, allowing the antenna to be embedded in slim devices such as tablet-based field mapping tools or IoT sensors mounted on infrastructure. Despite its size, the antenna’s design ensures that the ceramic patch has sufficient surface area to maintain the radiation efficiency required for RTK, proving that high precision does not have to come at the cost of form factor.

The antenna is equipped with an RF1.37mm coaxial cable, 100mm in length, a design that balances flexibility and signal integrity for RTK applications. The 1.37mm diameter cable is thin enough to be routed through the tight spaces of embedded devices, avoiding interference with other components while ensuring a direct path from the antenna to the RTK receiver. The 100mm length is carefully chosen to minimize signal loss—critical for RTK, where even 0.5 dB of additional loss can reduce the number of trackable satellites.

The cable’s braided copper shield provides 90%+ coverage, protecting the weak GNSS signals from electromagnetic interference (EMI) generated by nearby electronics such as motors, displays, or processors. EMI is a significant threat to RTK performance, as it can corrupt carrier-phase measurements and introduce positioning errors. By shielding the signal path, the cable ensures that the RTK receiver receives a clean input, enabling it to resolve ambiguities and maintain centimeter-level accuracy.

applications

The antenna is designed for applications including navigation modules, GNSS receivers, and OEM use, reflecting its versatility in high-precision systems. In navigation modules for autonomous robots, the antenna provides the raw signal data needed for real-time path correction, ensuring that the robot stays within centimeter-level tolerance of its intended route. In GNSS receivers for surveying equipment, it enables portable, backpack-mounted systems that deliver the same accuracy as traditional tripod-mounted setups.

For OEM use, the antenna’s compact size and standardized interface make it an ideal drop-in component for high-volume production. Manufacturers of drones, agricultural machinery, and smart infrastructure sensors can integrate the antenna without extensive redesign, leveraging its IPX connector and 50-ohm impedance to pair with existing RTK modules. This reduces development costs and accelerates the launch of new RTK-enabled products.

The antenna also supports OEM/ODM services, allowing customization to meet specific device requirements. This includes options for longer or shorter cables, alternative connectors (such as MHF4), or modified PCB layouts to fit unique form factors. For example, a manufacturer of precision drilling equipment may require a 200mm cable to route the antenna to an optimal position on the drill’s frame, while a developer of miniaturized surveying tools may need a custom PCB footprint to fit the antenna into a palm-sized device. This flexibility ensures that the antenna can adapt to the unique constraints of any RTK application.

The built-in GNSS RTK antenna finds practical use in a range of cutting-edge applications, each leveraging its compact size and high precision:

Precision Agriculture: Drones and ground robots equipped with the antenna map crop health, apply fertilizers, and plant seeds with centimeter-level accuracy. The antenna’s small size allows it to be integrated into lightweight drones, extending flight time while ensuring that treatment areas are covered precisely.

Industrial Robotics: Factory robots use the antenna to navigate assembly lines with sub-centimeter precision, ensuring that components are aligned correctly during manufacturing. The antenna’s linear polarization and stable gain pattern make it ideal for the fixed orientations of robotic arms and autonomous guided vehicles (AGVs).

Surveying and Mapping: Portable surveying tools, such as tablet-based systems, use the antenna to capture high-precision location data in the field. The antenna’s compact size makes these tools lightweight and easy to carry, while its RTK capabilities ensure that measurements meet industry standards for accuracy.

Smart Infrastructure: Sensors mounted on bridges, railways, and buildings use the antenna to monitor structural movement with millimetric precision. The antenna’s temperature resilience ensures reliable performance in outdoor environments, enabling long-term data collection for infrastructure health assessment.

Autonomous Drones: Delivery drones and inspection UAVs rely on the antenna for precise navigation, ensuring that they can land on small targets or inspect infrastructure with pinpoint accuracy. The antenna’s small size and low weight reduce drag, extending flight range while maintaining RTK lock.

In conclusion

-

In conclusion, the Built-in GNSS RTK Antenna represents a breakthrough in miniaturized high-precision positioning, proving that centimeter-level accuracy can be achieved in even the smallest devices. Its IPX connectivity and compact 25x25x4mm size enable seamless integration into drones, robots, and sensors, while its ceramic-PCB construction ensures durability and efficiency. The antenna’s linear polarization, multi-constellation frequency coverage, and temperature resilience make it suitable for diverse RTK applications, from agriculture to industrial automation. With support for OEM/ODM customization, it offers flexibility for manufacturers seeking to push the boundaries of what’s possible with embedded RTK technology. As the demand for compact, high-precision positioning grows, this antenna will play a pivotal role in enabling the next generation of RTK-enabled devices, ensuring that accuracy and miniaturization can coexist.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)