the automotive GNSS antenna’s signal transmission system

At the heart of the automotive GNSS antenna’s signal transmission system is its coaxial cable, available in two configurations: LMR100 and RG58. These cables are chosen for their ability to deliver low-loss RF performance in a compact, flexible form factor—essential for routing within the tight confines of a vehicle’s interior or exterior.

LMR100, a high-performance coaxial cable, is designed for applications where signal integrity is paramount. It features a solid copper-clad aluminum center conductor, a foam polyethylene dielectric, and a tinned copper braid shield, all contributing to its low attenuation characteristics. At the GNSS L1 frequency (1575.42 MHz), LMR100 exhibits attenuation of approximately 0.6 dB per meter, ensuring that weak satellite signals (as low as -160 dBm) reach the receiver with minimal loss. This is particularly critical for automotive applications, where the antenna is often mounted on the roof or dashboard, requiring cable runs that can extend several meters to reach the navigation unit or telematics control module.

RG58, a more traditional coaxial cable, offers a balance of performance and cost-effectiveness. While its attenuation at 1575 MHz is slightly higher (around 1.0 dB per meter) compared to LMR100, it remains suitable for shorter cable runs common in many vehicles. RG58 features a stranded copper center conductor, a polyethylene dielectric, and a braided copper shield, providing reliable performance in moderate RF environments. For manufacturers prioritizing cost without sacrificing basic functionality, RG58 serves as a viable alternative, ensuring that GNSS signals are transmitted with sufficient integrity for most navigation and telematics needs.

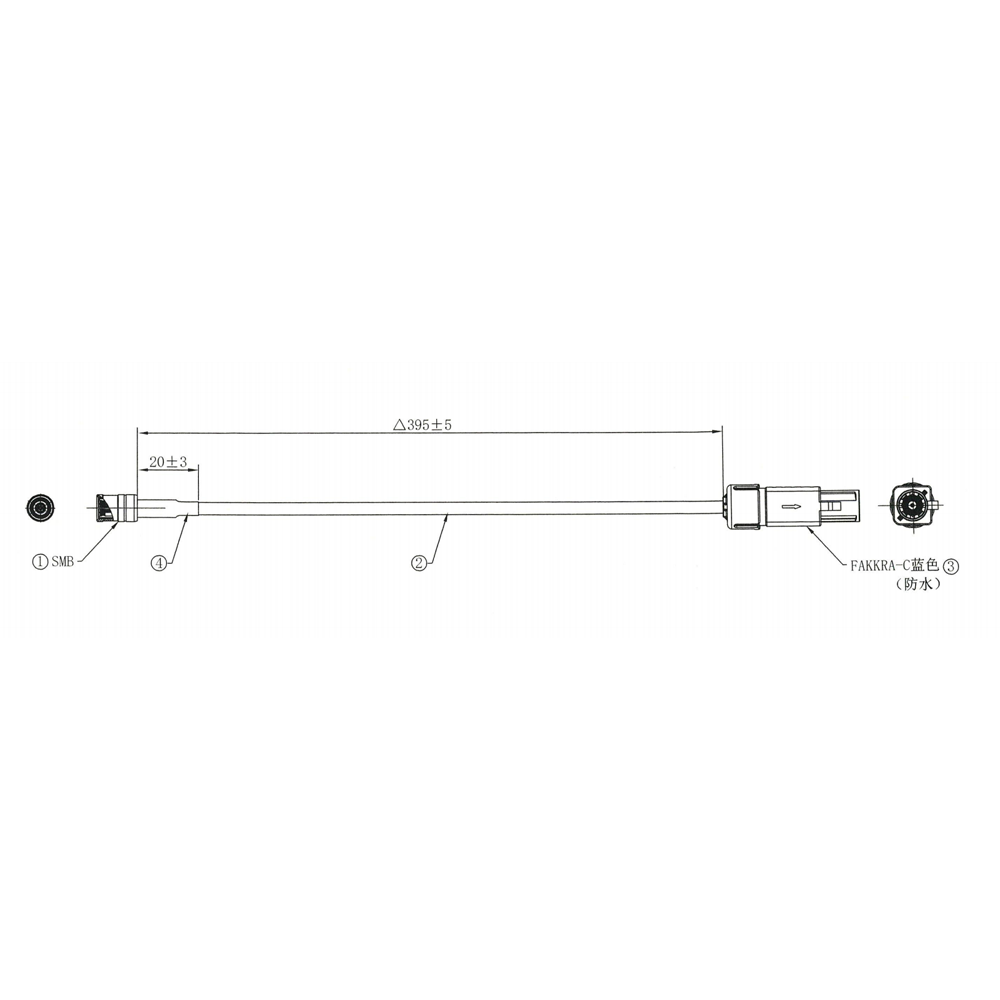

Both cable types share a cable length of 395 mm (approximately 15.5 inches), a dimension carefully chosen to balance flexibility and signal loss. This length is long enough to allow routing from the antenna’s typical mounting locations (e.g., roof, rear window, or dashboard) to the vehicle’s electronic control unit (ECU) while remaining short enough to minimize attenuation. In vehicles where longer runs are necessary, LMR100’s superior low-loss properties make it the preferred choice, ensuring that even with extended lengths, signal degradation remains within acceptable limits.

antenna’s connectivity

The antenna’s connectivity is defined by its dual connectors: Connector A (FAKRA-C Blue Male) and Connector B (SMB Female Pin), each serving a specific role in ensuring secure, interference-free signal transmission. FAKRA connectors, developed by the German automotive industry, have become the de facto standard for automotive RF applications due to their robust design, color-coding system, and keyed mating mechanism. The FAKRA-C Blue Male connector is specifically designated for GNSS applications, with its color and keying preventing incorrect mating with connectors intended for other RF systems (e.g., cellular, Wi-Fi, or AM/FM). This standardized approach reduces installation errors in manufacturing, ensuring that the antenna is connected to the correct port on the vehicle’s telematics module or navigation unit.

The FAKRA-C connector features a push-pull locking mechanism that provides a secure connection resistant to vibration—critical for automotive environments, where constant motion can loosen traditional threaded connectors. Its dielectric material is optimized for GNSS frequencies, ensuring stable impedance (50 ohms) and minimal insertion loss (typically less than 0.3 dB). Additionally, the FAKRA-C connector is designed to withstand the wide temperature fluctuations (-40°C to 85°C) common in vehicles, with materials that resist cracking or degradation under thermal stress.

Complementing the FAKRA-C connector is Connector B: SMB Female Pin, a compact, high-frequency connector used to interface with the antenna’s internal components (e.g., low-noise amplifier, LNA) or as a secondary connection point for auxiliary systems. SMB connectors are valued for their small size, making them ideal for integration into the antenna’s compact housing, and their snap-on locking mechanism, which ensures quick, secure mating during manufacturing. The female pin design provides a reliable electrical contact with the male counterpart, minimizing signal reflection and ensuring consistent impedance matching. For applications requiring secondary GNSS outputs (e.g., for both navigation and telematics), the SMB connector enables parallel signal distribution without significant loss, enhancing system flexibility.

Both connectors feature gold-plated contacts, a critical enhancement for ensuring long-term reliability in automotive environments. Gold plating provides excellent corrosion resistance, preventing oxidation that can degrade signal quality over time—particularly important in vehicles exposed to moisture, road salt, and humidity. The gold plating also reduces contact resistance, ensuring efficient signal transfer between the connector and its mating counterpart. In GNSS systems, where even minor resistance can introduce signal loss, this feature helps maintain the low-noise performance required to detect weak satellite signals.

antenna’s ability

The antenna’s ability to reject interference is enhanced by its shielding: Braided Tinned Copper, a multi-layered approach to blocking electromagnetic interference (EMI) and radio frequency interference (RFI). The braided shield, composed of tinned copper strands, forms a conductive barrier around the coaxial cable’s center conductor and dielectric, attenuating EMI from nearby vehicle systems such as engines, alternators, and electronic control modules. Tinned copper offers superior corrosion resistance compared to bare copper, ensuring that the shield maintains its conductivity even in harsh environments—an important consideration for vehicles operated in coastal areas or regions with heavy road salt use.

The braided shield provides 90-95% coverage of the cable, a level of protection sufficient to block most automotive EMI, which typically ranges from 100 kHz to 1 GHz. For higher-frequency interference (e.g., from cellular modems operating at 2 GHz), the shield’s tight braid density ensures attenuation levels exceeding 60 dB, preventing RFI from overwhelming the sensitive GNSS receiver. In electric and hybrid vehicles, where high-voltage systems can generate significant EMI, this shielding is particularly critical, ensuring that GNSS signals remain clear of noise that could cause positioning errors or signal loss.

The shield is electrically connected to the antenna’s ground plane and the vehicle’s chassis, creating a low-impedance path for interference to dissipate. This grounding strategy prevents EMI from reflecting back into the cable, further enhancing signal purity. For vehicles with advanced driver-assistance systems (ADAS) that rely on GNSS for lane-keeping and adaptive cruise control, this interference rejection is essential, as even minor positioning errors can compromise safety.

The antenna’s outer jacket color: Black serves both functional and aesthetic purposes. Functionally, the black jacket is typically made from UV-resistant polyethylene or PVC, protecting the cable from degradation caused by prolonged exposure to sunlight—critical for antennas mounted on the vehicle’s exterior (e.g., roof or rear window). UV resistance prevents the jacket from becoming brittle or cracking over time, ensuring that the shielding and internal conductors remain protected.

Aesthetically, the black color blends seamlessly with most vehicle exteriors and interiors, reducing visual intrusion. For antennas mounted in visible locations (e.g., on the dashboard or rear window), this subtlety enhances the vehicle’s design appeal, a key consideration for automotive manufacturers prioritizing interior aesthetics. The jacket also provides mechanical protection, resisting abrasion from routing through tight spaces (e.g., between door panels or under carpets) and ensuring the cable remains intact throughout the vehicle’s lifespan.

The automotive GNSS antenna is engineered to withstand extreme environmental conditions, as evidenced by its operating temperature range (-40°C to 85°C) and waterproof rating (Yes / IP67 Equivalent). The operating temperature range ensures reliable performance in climates ranging from the freezing cold of Siberian winters to the scorching heat of desert summers. In cold temperatures, the cable’s jacket and dielectric materials remain flexible, preventing cracking that could expose the conductors or shield. In high temperatures, the materials resist melting or deformation, maintaining the cable’s structural integrity and electrical performance.

The IP67-equivalent waterproof rating ensures that the antenna and its connectors are dust-tight and resistant to water immersion up to 1 meter for 30 minutes. This level of protection is critical for exterior-mounted antennas, which are exposed to rain, snow, and road spray. The waterproofing is achieved through gaskets and seals in the connectors and a water-resistant jacket, preventing moisture from entering the cable or antenna housing. Moisture ingress can cause corrosion of the conductors and shield, leading to increased signal loss or complete failure—risks that are mitigated by the IP67 rating, ensuring year-round reliability in all weather conditions.

Compliance with RoHS (Restriction of Hazardous Substances) standards underscores the antenna’s commitment to environmental responsibility and global regulatory compatibility. RoHS compliance ensures that the antenna is free from lead, mercury, cadmium, and other hazardous materials, making it suitable for sale in regions with strict environmental regulations, including the European Union, China, and California. This compliance is particularly important for automotive manufacturers operating in global markets, as it eliminates the need for region-specific antenna variants and simplifies supply chain management.

RoHS-compliant materials also contribute to the antenna’s durability, as they are often designed to withstand higher temperatures and chemical exposure compared to non-compliant alternatives. For example, the lead-free solder used in the connectors and internal components resists corrosion better than traditional lead-based solder, extending the antenna’s service life in harsh environments.

antenna’s internal design features

-

The antenna’s internal design features a single conductor (Number of Conductors: 1) composed of bare copper wire (Conductor Material: Bare Copper Wire), a configuration optimized for GNSS signal transmission. The single conductor serves as the center conductor of the coaxial cable, carrying the RF signal from the antenna’s radiating element to the receiver. Bare copper is chosen for its high electrical conductivity, minimizing signal loss and ensuring efficient transmission of weak GNSS signals. Unlike plated conductors, bare copper does not introduce additional resistance at the contact points, maintaining the low-noise performance required for GNSS applications.

The conductor’s material and design are complemented by the antenna’s internal components, including a low-noise amplifier (LNA) and band-pass filter. The LNA, typically with a noise figure below 1.5 dB, amplifies the weak satellite signals captured by the antenna’s radiating element (a ceramic patch optimized for RHCP, Right-Hand Circular Polarization, to match GNSS satellite signals). The band-pass filter suppresses out-of-band interference (e.g., from cellular or Wi-Fi signals), ensuring that only GNSS frequencies (1559–1610 MHz) reach the receiver. These components are integrated into a compact housing, often mounted on a metal ground plane that enhances radiation efficiency and provides additional shielding.

The automotive GNSS antenna’s functionality spans a wide range of critical vehicle systems, each relying on precise positioning and reliable signal reception:

Navigation Systems: The antenna provides real-time location data to in-car navigation units, enabling turn-by-turn directions, traffic updates, and points-of-interest search. Its ability to maintain signal lock in urban canyons (where tall buildings block satellite signals) and under dense foliage ensures that drivers receive accurate guidance in diverse environments.

Telematics and Connected Services: For fleet management, vehicle tracking, and remote diagnostics, the antenna enables precise location reporting, allowing fleet operators to monitor vehicle movements, optimize routes, and detect unauthorized use. In the event of an accident, the antenna’s GNSS data is used by emergency services (eCall) to dispatch assistance to the exact location, reducing response times.

Advanced Driver-Assistance Systems (ADAS): ADAS features such as adaptive cruise control, lane-keeping assist, and automated parking rely on GNSS data to determine the vehicle’s position relative to road markings, other vehicles, and obstacles. The antenna’s high precision and interference rejection ensure that these systems operate safely, even in complex traffic scenarios.

Autonomous Driving: For self-driving vehicles, which require centimeter-level positioning, the antenna works in conjunction with other sensors (LiDAR, radar) and differential GNSS (DGNSS) to provide absolute location data. Its low latency and high update rate (typically 10 Hz or higher) ensure that the vehicle’s control system has real-time positioning information to make split-second decisions.

Anti-Theft and Security: The antenna enables geofencing, allowing owners to set virtual boundaries and receive alerts if the vehicle enters or exits designated areas. In the event of theft, precise GNSS tracking helps law enforcement recover the vehicle quickly.

In real-world automotive environments, the antenna’s performance is tested against a unique set of challenges, from EMI generated by the vehicle’s own electronics to physical obstructions blocking satellite signals. In urban areas, where tall buildings reflect GNSS signals (causing multipath interference), the antenna’s RHCP polarization and band-pass filter help mitigate errors, ensuring positioning accuracy within 2–5 meters. On highways, where vehicles travel at high speeds, the antenna’s fast signal acquisition (typically <10 seconds) ensures that navigation remains continuous, even when passing through tunnels or under overpasses.

For electric vehicles (EVs), which generate more EMI due to their high-voltage battery systems, the antenna’s braided shielding and grounding strategy are critical, preventing interference from disrupting GNSS reception. In hybrid vehicles, which switch between internal combustion and electric modes, the antenna maintains consistent performance regardless of the power source, ensuring uninterrupted navigation and telematics.

In conclusion

-

In conclusion, the automotive GNSS antenna is a marvel of engineering that combines precision RF design with rugged durability to meet the demands of modern vehicles. Its LMR100/RG58 coaxial cable, FAKRA and SMB connectors, and braided shielding ensure reliable signal transmission, while its waterproofing, wide temperature range, and RoHS compliance make it suitable for global automotive markets. From basic navigation to autonomous driving, this antenna is a critical component enabling the connected, safe, and efficient vehicles of today and tomorrow. As automotive technology continues to advance, with a growing emphasis on connectivity and automation, the role of the GNSS antenna will only become more central, underscoring its importance in the future of transportation.

Language

Language

En

En Cn

Cn Korean

Korean

Home >

Home >

18665803017 (Macro)

18665803017 (Macro)